Abrasion Testing on Curved Surfaces

The Importance of Abrasion Testing on Curved Surfaces Ensuring Product Reliability and Safety

In todays fast-paced business world, companies are under constant pressure to produce high-quality products that meet the demands of their customers while maintaining a competitive edge in the market. One crucial aspect of ensuring product reliability and safety is conducting thorough testing and evaluation procedures. Among these tests, Abrasion Testing on Curved Surfaces stands out as an essential service for businesses looking to verify the durability and performance of their products.

What is Abrasion Testing on Curved Surfaces?

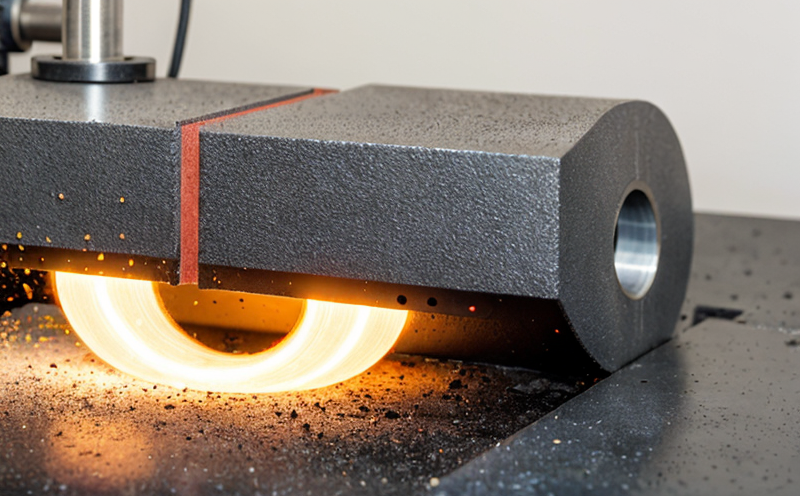

Abrasion Testing on Curved Surfaces is a specialized laboratory service designed to assess the wear resistance of curved surfaces on various materials. This test evaluates how well a material can withstand abrasive forces, such as friction or erosion, which can cause wear and tear on its surface. By subjecting the sample to controlled abrasion conditions, our expert technicians at Eurolab can determine the materials ability to maintain its shape and functionality under various environmental factors.

The Advantages of Abrasion Testing on Curved Surfaces

Abrasion Testing on Curved Surfaces offers numerous benefits for businesses looking to ensure product reliability and safety. Some of the key advantages include

Improved Product Reliability By testing the wear resistance of curved surfaces, companies can identify potential weaknesses in their products and make informed decisions about design modifications or material substitutions.

Enhanced Safety Features Abrasion Testing on Curved Surfaces helps prevent accidents caused by faulty or worn-out parts, ultimately reducing liability risks for businesses.

Increased Product Lifespan By evaluating the durability of curved surfaces, companies can optimize their products lifespan and reduce maintenance costs.

Compliance with Industry Standards Our expert technicians at Eurolab ensure that all Abrasion Testing on Curved Surfaces is conducted in accordance with relevant industry standards and regulations.

Key Benefits of Using Abrasion Testing on Curved Surfaces

Some key benefits of using Abrasion Testing on Curved Surfaces include

Comprehensive Analysis Our comprehensive analysis provides a thorough understanding of the materials wear resistance, enabling informed decision-making.

Customizable Test Conditions We can tailor test conditions to simulate specific environmental factors, such as temperature or humidity, to accurately reflect real-world usage scenarios.

Rapid Turnaround Times Our state-of-the-art facilities and experienced technicians enable fast turnaround times without compromising on quality.

QA Frequently Asked Questions about Abrasion Testing on Curved Surfaces

Q What types of materials can be tested using Abrasion Testing on Curved Surfaces?

A Various materials, including metals, polymers, ceramics, and composites, can be tested for their wear resistance on curved surfaces.

Q Why is Abrasion Testing on Curved Surfaces essential for businesses?

A Abrasion Testing on Curved Surfaces helps ensure product reliability and safety by identifying potential weaknesses in materials and preventing accidents caused by worn-out parts.

Q How do you conduct Abrasion Testing on Curved Surfaces at Eurolab?

A Our expert technicians use specialized equipment to subject the sample to controlled abrasion conditions, simulating real-world usage scenarios. The test results are then analyzed and reported in detail.

Q Can I customize the testing parameters to suit my specific needs?

A Yes, we can tailor test conditions to simulate specific environmental factors or usage scenarios. Our experienced technicians will work closely with you to ensure that all testing meets your requirements.

Why Choose Eurolab for Abrasion Testing on Curved Surfaces?

At Eurolab, our team of expert technicians is dedicated to providing high-quality laboratory services, including Abrasion Testing on Curved Surfaces. With years of experience in the industry and access to state-of-the-art facilities, we can offer

Comprehensive Analysis Our thorough analysis provides a comprehensive understanding of the materials wear resistance.

Customizable Test Conditions We tailor test conditions to simulate specific environmental factors or usage scenarios.

Rapid Turnaround Times Fast turnaround times without compromising on quality.

By choosing Eurolab for Abrasion Testing on Curved Surfaces, businesses can ensure product reliability and safety while reducing liability risks. Dont compromise on the quality of your products trust our expert technicians to deliver accurate and reliable results.