Additive residue analysis in high-temperature packaging

The Importance of Additive Residue Analysis in High-Temperature Packaging Why Your Business Needs It

In todays fast-paced and competitive business environment, ensuring the safety and quality of your products is paramount. With the increasing demand for packaged goods, companies are seeking innovative solutions to maintain product integrity while meeting regulatory requirements. One critical aspect that often goes unnoticed is the potential presence of additives in high-temperature packaging materials. Additive residue analysis in high-temperature packaging has become a vital laboratory service that can make all the difference between compliance and non-compliance.

At Eurolab, our team of experts specializes in providing cutting-edge analytical services to help businesses like yours navigate this complex landscape. In this article, well delve into the world of additive residue analysis in high-temperature packaging, highlighting its significance, benefits, and what it means for your business.

What is Additive Residue Analysis in High-Temperature Packaging?

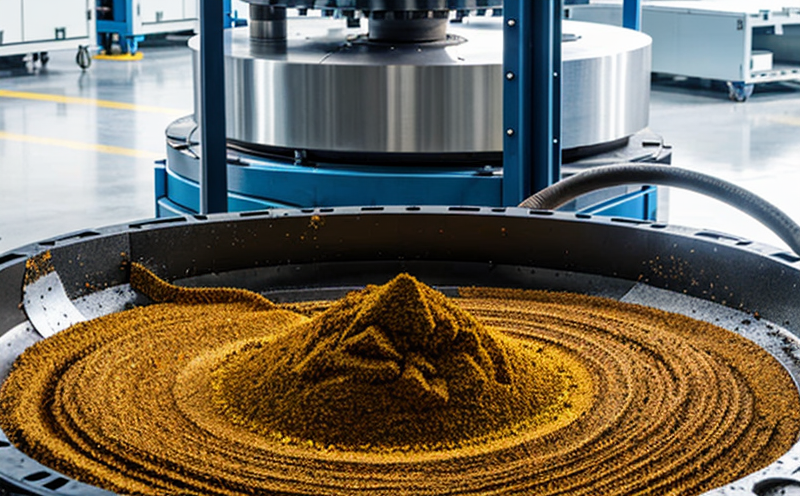

Additive residue analysis in high-temperature packaging involves the detection and quantification of residual additives left behind after manufacturing processes. These additives can include a range of chemicals, such as plasticizers, lubricants, or flame retardants, which are used to improve the performance and durability of packaging materials.

However, when exposed to high temperatures during processing, storage, or transportation, these additives can break down and release volatile organic compounds (VOCs) into the packaging material. These residual additives can then migrate onto packaged products, posing potential risks to consumer health and safety.

The Advantages of Additive Residue Analysis in High-Temperature Packaging

By incorporating additive residue analysis in high-temperature packaging into your quality control protocol, you can enjoy numerous benefits that will set your business apart from the competition

Compliance with Regulatory Requirements With the increasing scrutiny on product safety and environmental sustainability, regulatory bodies worldwide are cracking down on companies that fail to meet standards. Additive residue analysis ensures compliance with regulations, protecting your business from costly fines and reputational damage.

Product Integrity and Safety By detecting potential hazards associated with additive residues, you can ensure that packaged products are safe for consumption, minimizing the risk of recalls and liability claims.

Enhanced Quality Control Additive residue analysis provides a critical layer of quality control, enabling you to verify the integrity of your packaging materials and detect any anomalies before they become major issues.

Cost Savings By identifying potential problems early on, you can avoid costly rework, waste disposal, or even product destruction. Our expert analysis helps you optimize production processes and minimize losses.

Increased Customer Trust With Eurolabs additive residue analysis services, you can demonstrate your commitment to quality and customer safety, fostering trust with your clients and differentiating yourself from competitors.

Key Benefits of Additive Residue Analysis

Here are some key advantages of incorporating additive residue analysis in high-temperature packaging into your business strategy

Reduced Risk of Contamination By detecting residual additives, you can minimize the risk of contamination and ensure that packaged products meet regulatory standards.

Improved Product Shelf Life Our expert analysis helps identify potential issues with packaging materials, enabling you to extend product shelf life and reduce waste.

Enhanced Environmental Sustainability With Eurolabs additive residue analysis services, you can reduce your environmental footprint by minimizing waste and improving supply chain efficiency.

Competitive Advantage By demonstrating a commitment to quality and customer safety, you can differentiate your business from competitors and attract loyal customers.

Frequently Asked Questions (FAQs)

We understand that our laboratory service may raise questions. Here are some answers to common queries

Q What types of additives can be detected through additive residue analysis?

A Our expert team detects a wide range of residual additives, including plasticizers, lubricants, and flame retardants.

Q How is additive residue analysis conducted at Eurolab?

A We employ advanced analytical techniques, such as GC-MS (Gas Chromatography-Mass Spectrometry) and LC-MS (Liquid Chromatography-Mass Spectrometry), to detect and quantify residual additives.

Q Can I trust the results from Eurolabs additive residue analysis services?

A Absolutely. Our team of experts follows ISO/IEC 17025 accredited procedures, ensuring that all analytical results are accurate, reliable, and compliant with regulatory requirements.

Q How long does it take to receive results from additive residue analysis?

A Turnaround times vary depending on the complexity of the samples and the type of analysis required. Our dedicated team will work closely with you to ensure timely delivery of results.

Conclusion

In todays competitive business environment, ensuring product safety, quality, and compliance is paramount. Additive residue analysis in high-temperature packaging has become a vital laboratory service that can make all the difference between success and failure. At Eurolab, our expert team specializes in providing cutting-edge analytical services to help businesses like yours navigate this complex landscape.

Dont compromise on product integrity or risk regulatory non-compliance. Choose Eurolabs additive residue analysis services to ensure the quality and safety of your packaged products. Contact us today to learn more about how our laboratory can support your business needs.