Assessing the compatibility of composite materials with aggressive chemicals used in industrial applications

Assessing Compatibility Ensuring Industrial Success with Eurolabs Expertise

In todays fast-paced industrial landscape, manufacturers are constantly seeking innovative materials and solutions to drive efficiency, productivity, and profitability. Among the vast array of options available, composite materials have emerged as a preferred choice due to their exceptional strength-to-weight ratio, durability, and versatility. However, one crucial aspect often overlooked is the compatibility of these materials with aggressive chemicals commonly used in industrial processes.

What is Assessing Compatibility?

Assessing the compatibility of composite materials with aggressive chemicals refers to the process of evaluating how a material will react when exposed to harsh substances, such as acids, bases, solvents, or oxidizing agents. This evaluation helps manufacturers determine whether their chosen material can withstand the rigors of industrial applications without compromising its integrity or performance.

Why is Assessing Compatibility Essential?

The consequences of incompatibility between composite materials and aggressive chemicals can be devastating for businesses. Damage to equipment, product contamination, reduced lifespan, and even environmental hazards are just a few potential outcomes. To mitigate these risks, manufacturers must assess the compatibility of their chosen materials before integrating them into industrial processes.

Key Benefits of Assessing Compatibility with Eurolab

Our laboratory service at Eurolab is designed to provide accurate and reliable assessments of composite material compatibility. By choosing our expert services, you can

Ensure product quality and reliability Avoid potential damage to equipment and products caused by incompatibility between materials and chemicals.

Reduce downtime and maintenance costs Minimize the risk of production interruptions due to material failures or damage.

Increase employee safety Protect your workforce from exposure to hazardous substances by selecting compatible materials.

Meet regulatory requirements Comply with industry standards and environmental regulations by choosing materials that meet specified chemical resistance levels.

Optimize material selection Make informed decisions about material choice based on our comprehensive assessments, reducing the likelihood of costly mistakes.

Enhance product lifespan Select materials that can withstand the harshest industrial conditions, extending the life of your products.

How Does Eurolabs Assessing Compatibility Service Work?

Our team of experienced chemists and engineers utilizes advanced laboratory equipment to subject composite materials to a range of aggressive chemicals. We conduct thorough assessments, including

Chemical exposure Materials are exposed to various concentrations and types of chemicals under controlled conditions.

Visual inspection Materials are visually inspected for signs of degradation or damage.

Mechanical testing Samples are subjected to mechanical stress to evaluate their integrity after chemical exposure.

QA Frequently Asked Questions

Q What types of composite materials can be assessed?

A Eurolabs experts assess a wide range of composite materials, including polymers, carbon fibers, glass fibers, and hybrid composites.

Q How long does the assessment process take?

A The duration of the assessment depends on the complexity of the test protocol. Our team will provide you with a detailed timeline after discussing your specific requirements.

Q What types of chemicals are commonly tested for compatibility?

A Eurolab assesses the compatibility of composite materials with common industrial chemicals, including acids (e.g., hydrochloric acid), bases (e.g., sodium hydroxide), solvents (e.g., acetone), and oxidizing agents (e.g., hydrogen peroxide).

Q Can you provide certification or documentation for compliance?

A Yes, Eurolab provides detailed reports outlining the test results, including any observed effects of chemical exposure on the material. We also offer certification to support regulatory requirements.

Conclusion

In todays competitive industrial landscape, manufacturers must prioritize quality and reliability above all else. By assessing the compatibility of composite materials with aggressive chemicals, businesses can minimize risks, optimize material selection, and ensure product quality. Trust Eurolabs expert services to guide you through this critical process, safeguarding your operations and protecting your bottom line.

-

Testing chemical resistance of materials in various industrial environments

-

Evaluating how different materials react when exposed to specific chemicals

-

Assessing the long-term compatibility of materials with various chemical substances

-

Determining how chemicals affect the physical properties of metals, plastics, and ceramics

-

Simulating material failure under different chemical exposures in manufacturing processes

-

Evaluating the impact of chemical exposure on material integrity in harsh environments

-

Ensuring that chemical formulations do not compromise the strength or performance of materials

-

Assessing compatibility with materials used in packaging, coatings, and containers

-

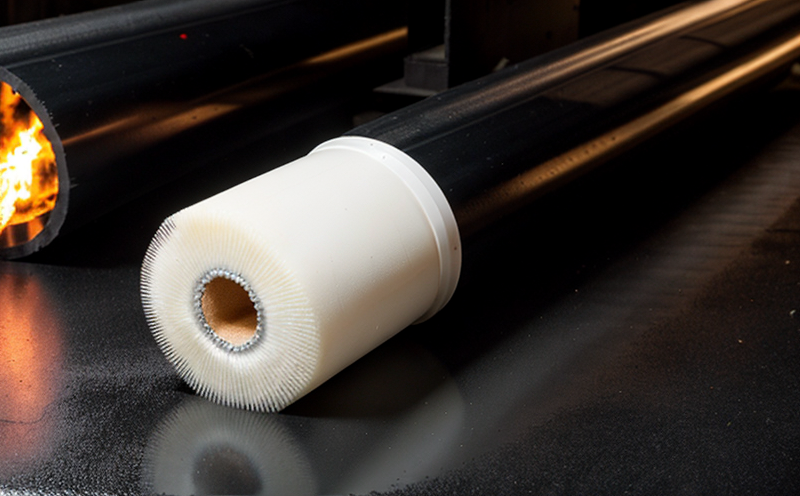

Testing the impact of aggressive chemicals on seals, gaskets, and other critical components

-

Evaluating the interaction between different chemicals and materials used in consumer products

-

Testing the effect of chemical exposure on elastomers and rubber materials

-

Ensuring that chemicals do not cause degradation or corrosion of equipment, pipelines, or tanks

-

Simulating different chemical exposure scenarios to determine material suitability and durability

-

Testing materials for compatibility with chemicals at different temperatures, pressures, and conditions

-

Evaluating chemical interactions between two or more substances and their effect on material properties

-

Testing the compatibility of materials used in the automotive, aerospace, and medical industries with chemicals

-

Determining the best material choices for applications involving aggressive chemical environments

-

Testing the effects of chemical exposure on surface finishes, including coatings and plating

-

Ensuring the safe use of chemicals in consumer goods by testing material compatibility for health and safety

-

Evaluating the stability of materials over time when exposed to chemicals in manufacturing and storage

-

Determining the performance of coatings and films when exposed to various chemicals used in industrial processes