Assessing the Impact of ESD on PCB Layouts

Assessing the Impact of ESD on PCB Layouts A Critical Laboratory Service for Ensuring Board Reliability

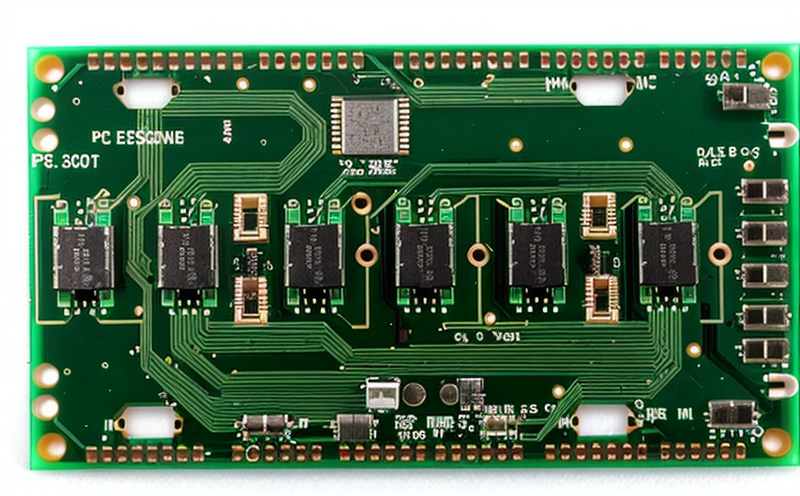

In todays fast-paced electronics industry, designing and manufacturing Printed Circuit Boards (PCBs) is a complex process that requires meticulous attention to detail. One critical factor that can make or break a PCBs performance is Electrostatic Discharge (ESD), a sudden flow of electricity that can damage sensitive components and compromise the entire boards reliability. To mitigate this risk, Eurolab offers a specialized laboratory service Assessing the Impact of ESD on PCB Layouts. In this article, we will delve into the importance of this service, its key benefits, and address frequently asked questions to help businesses understand why it is an essential tool for ensuring board reliability.

What is ESD and Why is it a Concern?

ESD is a common phenomenon that occurs when there is a transfer of static electricity between two objects. In the context of PCBs, ESD can be caused by various factors such as human contact, metal tools, or even environmental conditions like humidity and temperature fluctuations. When an ESD event occurs, it can lead to damage to sensitive components, including microcontrollers, memory chips, and other integrated circuits.

If left unchecked, ESD can result in a range of issues, from minor component failure to complete board destruction. This not only leads to costly repairs but also impacts product quality, reliability, and customer satisfaction. In fact, according to industry estimates, ESD-related failures account for up to 30 of all PCB failures.

The Advantages of Assessing the Impact of ESD on PCB Layouts

Eurolabs laboratory service is specifically designed to identify potential ESD risks and provide actionable recommendations to mitigate them. Here are some key benefits of using this service

Improved Board Reliability By assessing the impact of ESD on your PCB layout, our experts can help you design boards that are resistant to static electricity, ensuring a significant reduction in component failures.

Reduced Costs Identifying and addressing ESD-related issues early on can save businesses thousands of dollars in repair costs and lost productivity.

Increased Productivity With a reliable board design, manufacturers can streamline their production processes, reducing the risk of rework and improving overall efficiency.

Enhanced Quality Control Our laboratory service ensures that your PCBs meet strict quality standards, giving you peace of mind and confidence in your products.

Compliance with Industry Standards Eurolabs ESD assessment services ensure that your boards comply with industry standards and regulations, reducing the risk of non-compliance and associated penalties.

Key Benefits

Customized Solutions Our expert engineers work closely with you to understand your specific requirements and develop tailored solutions to address ESD-related issues.

State-of-the-Art Equipment We utilize cutting-edge equipment and technology to simulate real-world ESD scenarios, providing accurate and reliable results.

Expert Analysis Our experienced team provides thorough analysis of your PCB layout, identifying potential ESD risks and recommending corrective actions.

Fast Turnaround Time We understand the importance of timely delivery, ensuring that our reports are completed quickly without compromising on accuracy or quality.

Frequently Asked Questions

Q How does Eurolabs Assessing the Impact of ESD on PCB Layouts service work?

A Our expert engineers will review your PCB design and layout to identify potential ESD risks. We use state-of-the-art equipment to simulate real-world ESD scenarios, providing accurate and reliable results.

Q What types of PCBs can be assessed for ESD impact?

A Eurolabs laboratory service is suitable for a wide range of PCB designs, including high-speed digital boards, analog circuits, and mixed-signal boards.

Q How long does the assessment process take?

A Our turnaround time is typically 2-4 weeks, depending on the complexity of the project and the volume of work.

Q Can I trust Eurolabs ESD assessment results?

A Absolutely! Our team consists of experienced engineers with a deep understanding of ESD-related issues. We guarantee accurate and reliable results that you can rely on to make informed design decisions.

Q What if I have specific requirements or questions about the assessment process?

A Please dont hesitate to contact us. Our expert engineers are always available to discuss your project requirements, address any questions or concerns, and provide guidance throughout the assessment process.

Conclusion

In todays competitive electronics market, ensuring board reliability is crucial for businesses looking to maintain customer satisfaction, quality standards, and profitability. Eurolabs Assessing the Impact of ESD on PCB Layouts laboratory service provides a critical tool for designers and manufacturers to identify and mitigate potential ESD-related issues. By leveraging our expertise and state-of-the-art equipment, you can design boards that are resistant to static electricity, reducing component failures and associated costs.

Dont compromise your products reliability and performance. Trust Eurolabs ESD assessment service to ensure that your PCBs meet the highest standards of quality and safety. Contact us today to learn more about our laboratory services and how we can help you achieve board reliability excellence!