Assessing the resistance of coatings to high-velocity impacts and abrasives

Assessing the Resistance of Coatings to High-Velocity Impacts and Abrasives Ensuring Durability and Performance

In todays fast-paced industrial landscape, coatings play a vital role in protecting surfaces from wear and tear, corrosion, and damage caused by environmental factors. However, even the most robust coatings can be susceptible to high-velocity impacts and abrasives, which can compromise their integrity and lead to costly repairs or replacements. To mitigate this risk, Eurolab offers a comprehensive laboratory service that assesses the resistance of coatings to high-velocity impacts and abrasives.

What is Assessing the Resistance of Coatings to High-Velocity Impacts and Abrasives?

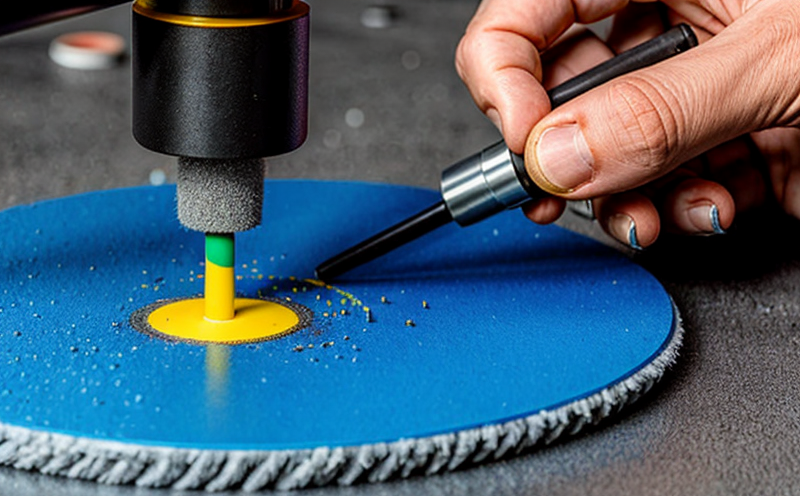

Assessing the resistance of coatings to high-velocity impacts and abrasives involves subjecting coated samples to controlled conditions that simulate real-world scenarios. This laboratory service employs advanced testing equipment and methodologies to evaluate the coatings ability to withstand various forms of mechanical stress, including

High-velocity impacts (e.g., bullets, shrapnel)

Abrasion (e.g., sandblasting, chemical etching)

The primary objective of this assessment is to determine whether the coating meets specific performance standards or regulations. By evaluating the coatings resistance to high-velocity impacts and abrasives, businesses can ensure that their products meet or exceed industry requirements for durability and reliability.

Why is Assessing the Resistance of Coatings to High-Velocity Impacts and Abrasives Essential?

The importance of assessing coatings resistance to high-velocity impacts and abrasives cannot be overstated. Some key reasons why this laboratory service is crucial include

Cost Savings By identifying potential weaknesses in coating performance, businesses can avoid costly repairs or replacements due to premature wear and tear.

Enhanced Product Reliability Regular assessments ensure that coatings meet or exceed industry standards for durability and reliability, promoting customer satisfaction and loyalty.

Reduced Liability Demonstrating compliance with regulatory requirements through regular assessments reduces the risk of liability claims related to product failure.

Competitive Advantage Companies that prioritize coating performance can differentiate themselves from competitors, driving market share and revenue growth.

Key Benefits of Assessing Coatings Resistance

Here are some key benefits of assessing coatings resistance to high-velocity impacts and abrasives

Improved Coating Selection By understanding the performance characteristics of various coatings, businesses can select the most suitable materials for their applications.

Enhanced Product Design Regular assessments inform product design decisions, enabling companies to optimize coating selection and application techniques.

Reduced Material Waste Minimizing material waste through targeted coating selection reduces costs and minimizes environmental impact.

Increased Customer Satisfaction Demonstrating commitment to quality and performance fosters trust between businesses and their customers.

How Does Eurolabs Laboratory Service Work?

Eurolabs laboratory service employs state-of-the-art equipment and methodologies to evaluate coatings resistance to high-velocity impacts and abrasives. The process typically involves the following steps

Sample Preparation Coated samples are carefully prepared for testing, taking into account any relevant industry standards or regulations.

High-Velocity Impact Testing Samples are subjected to controlled high-velocity impacts using specialized equipment (e.g., ballistic testing machines).

Abrasion Testing Samples undergo abrasion testing using various methods (e.g., sandblasting, chemical etching).

Data Analysis and Reporting Results from both tests are analyzed and presented in a comprehensive report detailing the coatings performance.

QA Frequently Asked Questions

Here are some frequently asked questions about Eurolabs laboratory service

Q What types of coatings can be tested?

A Eurolabs laboratory service evaluates various types of coatings, including paint, powder coatings, and liquid coatings.

Q How long does the testing process typically take?

A The duration of testing depends on the specific requirements of each project, but typical test durations range from a few days to several weeks.

Q What are the advantages of outsourcing coating performance assessments?

A Outsourcing coating performance assessments allows businesses to leverage specialized expertise and equipment, ensuring accuracy and reliability in their results.

Conclusion

Assessing the resistance of coatings to high-velocity impacts and abrasives is a critical component of any businesss quality control strategy. Eurolabs comprehensive laboratory service provides companies with the insights they need to optimize coating performance, reduce costs, and enhance product reliability. By partnering with Eurolab, businesses can ensure that their products meet or exceed industry standards for durability and performance.

Dont risk compromising your products integrity due to inadequate coating performance. Contact Eurolab today to learn more about our laboratory service and how we can help you assess the resistance of coatings to high-velocity impacts and abrasives.