The Importance of Bending Strength Test Ensuring Your Materials Can Withstand the Test

In todays fast-paced manufacturing industry, businesses are constantly seeking ways to improve product quality, reduce costs, and increase customer satisfaction. One crucial aspect that often gets overlooked is the physical properties of materials used in production. This is where Eurolab comes in a leading provider of laboratory services that can help you assess the strength and durability of your materials through our Bending Strength Test.

What is Bending Strength Test?

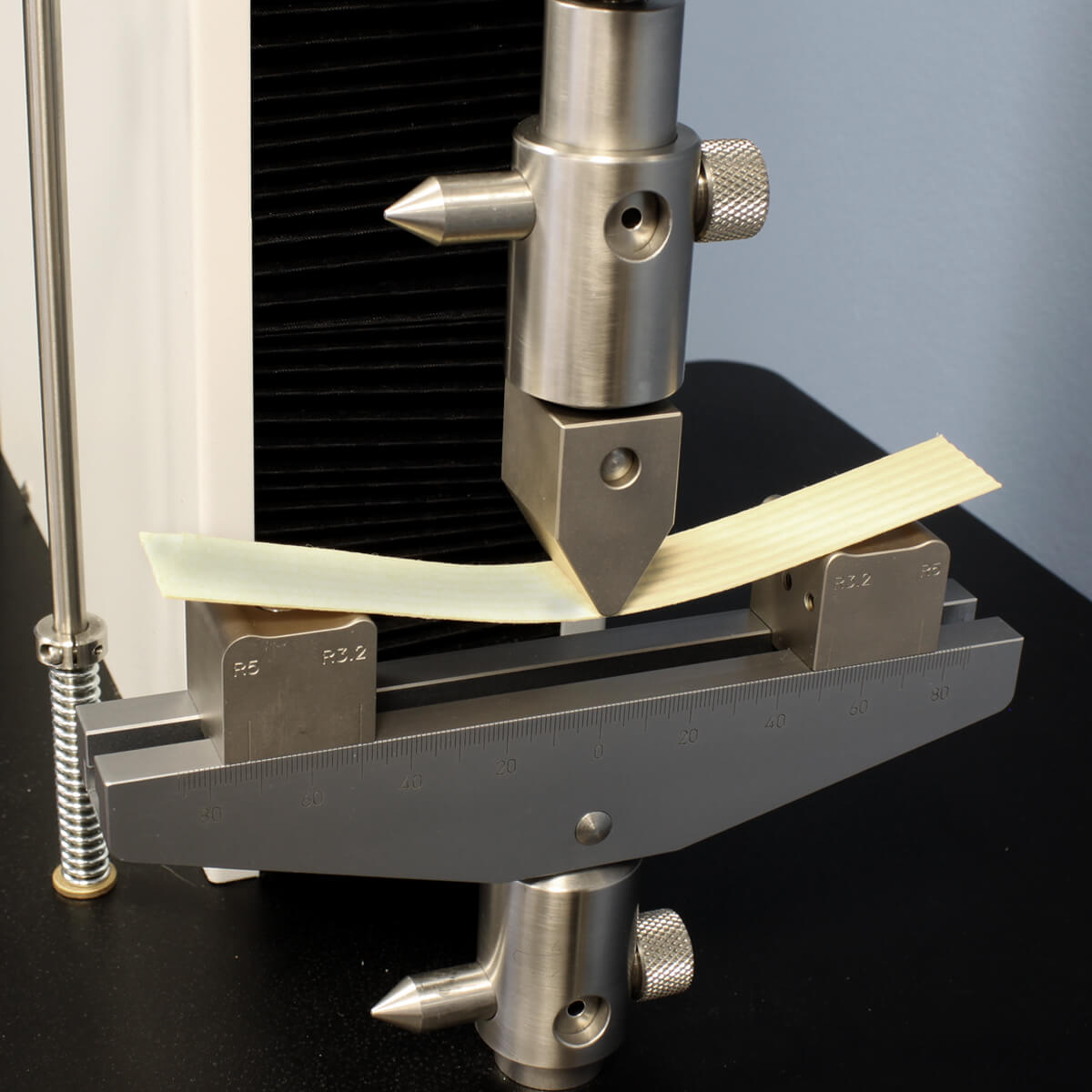

Bending Strength Test, also known as flexural strength test or three-point bending test, is a widely used method to determine the maximum stress a material can withstand without failing. Its an essential evaluation that helps manufacturers identify the mechanical properties of their products and make informed decisions about material selection, design optimization, and production processes.

In simple terms, Bending Strength Test measures how well your materials can resist deformation under external forces. This test is usually performed on samples taken from various parts of a product to ensure uniformity and consistency in quality.

Why is Bending Strength Test essential for businesses?

The benefits of using Bending Strength Test are numerous, and heres why its an indispensable tool for companies across various industries

Improved Product Quality By assessing the mechanical properties of materials, manufacturers can identify potential issues before they reach production, ensuring higher quality products that meet customer expectations.

Reduced Costs Conducting Bending Strength Test helps avoid costly mistakes associated with material failures, reducing waste, and minimizing losses due to rework or scrap.

Enhanced Safety Materials that undergo this test are less likely to fail catastrophically, posing a risk to human life and safety. Companies can rest assured that their products will perform as expected in various operating conditions.

Competitive Advantage A thorough understanding of material properties gives manufacturers an edge over competitors who may not have conducted similar tests. This enables companies to create innovative products with superior performance characteristics.

Benefits for Specific Industries

The advantages of Bending Strength Test are not limited to a single industry; rather, its a versatile tool that benefits various sectors

Aerospace and Defense Materials used in aircraft and defense equipment must exhibit exceptional strength-to-weight ratios. Eurolabs Bending Strength Test helps ensure compliance with stringent regulations and standards.

Automotive and Transportation Manufacturers of car parts, bike frames, or other vehicle components rely on our testing services to guarantee the reliability and safety of their products.

Construction and Building Materials Testing materials used in construction ensures that they can withstand environmental factors like weathering, temperature fluctuations, and load variations.

Key Benefits for Companies

Eurolabs Bending Strength Test offers numerous benefits for companies seeking to optimize product quality, reduce costs, and stay ahead of the competition

Increased Efficiency By identifying potential issues early on, manufacturers can streamline production processes, reducing downtime and increasing overall efficiency.

Better Material Selection Our testing services enable companies to choose materials that meet their specific requirements, ensuring optimal performance and minimizing material waste.

Compliance with Regulations Eurolabs Bending Strength Test helps ensure compliance with industry-specific regulations and standards, mitigating the risk of fines, recalls, or reputation damage.

QA Section

We understand you may have some questions about our Bending Strength Test services. Here are some frequently asked questions to help you better comprehend what we offer

Q What types of materials can be tested using Bending Strength Test?

A Eurolabs Bending Strength Test can be performed on a wide range of materials, including metals (aluminum, steel, titanium), plastics, composites, and ceramics.

Q How long does the testing process take?

A The duration of our Bending Strength Test is relatively short, typically taking anywhere from 30 minutes to several hours, depending on the material type and test requirements.

Q What are the advantages of outsourcing this testing service to Eurolab?

A By partnering with Eurolab, companies can leverage our expertise, state-of-the-art equipment, and experienced personnel to ensure accurate results and faster turnaround times.

Q Can I trust Eurolabs results?

A Absolutely! Our team follows strict quality control procedures and adheres to industry-standard protocols to guarantee the reliability of our test results.

-

Testing the ability of materials in toys to withstand bending without breaking or cracking

-

Evaluating the structural integrity of toys under bending stress, ensuring that they do not deform easily

-

Simulating real-world play to assess whether toys with flexible parts maintain their shape after bending

-

Ensuring that toys with bendable features, such as soft plastic or rubber parts, resist permanent deformation

-

Verifying the strength of toy components, such as limbs, joints, or handles, against excessive bending forces

-

Testing materials used in toys to ensure they have adequate flexibility while maintaining durability

-

Ensuring that toys with elastic or flexible components do not break when bent or twisted during play

-

Testing whether toys retain their functionality after being bent or deformed during typical usage

-

Verifying that toys designed for bending or flexing return to their original shape after being manipulated

-

Ensuring that toys with materials such as foam, plastic, or rubber remain intact when subjected to bending forces

-

Simulating the repeated bending or flexing of toys to test long-term durability and resistance to wear

-

Testing the bending strength of toys designed for older children to ensure they can handle more intense play

-

Verifying that toys with multiple bendable parts do not weaken or break under repeated play

-

Testing toys with adjustable parts to ensure their bending points remain functional over time

-

Ensuring that the toy’s design maintains strength in areas likely to experience bending forces, like handles or limbs

-

Verifying that bending does not affect the safety or usability of toys, particularly those with sharp or moving parts

-

Testing for durability in toys that require bending or compression as part of their interactive features

-

Assessing toys for any potential risk of injury from sharp bends that could create hazardous edges

-

Ensuring that the materials used in toys can handle sudden or extreme bending without failure

-

Verifying that toys with soft materials or stuffing do not lose their shape after bending or pressing

-

Testing toys with reinforced parts to ensure they do not break under bending or twisting pressure

-

Ensuring that toys with moveable or flexible features provide enough resistance to bending without loss of form