Unlocking Reliability The Critical Importance of Cable Harness Testing in Todays Competitive Market

In todays fast-paced world of electronics and technology, the reliability of products has become an essential aspect for businesses to stay ahead of the competition. With increasingly complex designs and rapidly evolving technologies, ensuring that electronic components function flawlessly is more crucial than ever. This is where Cable Harness Testing comes into play a laboratory service provided by Eurolab that helps manufacturers validate the integrity of their cable harnesses.

What is Cable Harness Testing?

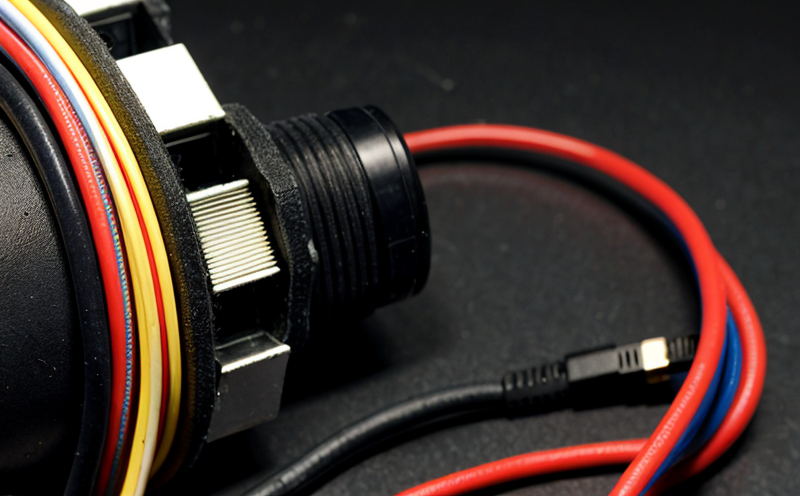

A cable harness, also known as a wire harness or loom, is an assembly of cables and wires used to connect electronic components within a device. Its a critical component in many modern products, including vehicles, medical devices, industrial machinery, and consumer electronics. However, the reliability and performance of a product are only as good as its weakest link and for many manufacturers, that link is the cable harness.

Cable Harness Testing is a thorough examination of the cable harness to ensure it meets or exceeds industry standards. This process involves evaluating various parameters such as electrical continuity, insulation resistance, temperature range, vibration resistance, and more. By subjecting the cable harness to rigorous testing conditions, Eurolabs laboratory services enable manufacturers to identify potential issues before they cause costly delays, recalls, or even product failures.

The Advantages of Cable Harness Testing

Using Cable Harness Testing can bring numerous benefits to businesses, including

Improved Product Reliability By identifying and addressing potential issues early on, manufacturers can ensure their products meet the highest standards of reliability.

Reduced Warranty Claims Products that pass rigorous testing are less likely to experience failures, resulting in lower warranty claims and associated costs.

Enhanced Safety Features Cable Harness Testing helps identify potential electrical shock hazards or thermal runaway risks, ensuring products are safer for users.

Increased Efficiency Manufacturers can reduce the time spent on troubleshooting and debugging by catching issues during testing rather than after product release.

Compliance with Regulations By adhering to industry standards and regulations, manufacturers can avoid costly fines and penalties associated with non-compliance.

Competitive Advantage Companies that prioritize Cable Harness Testing demonstrate their commitment to quality and reliability, setting them apart from competitors.

Risk Mitigation Identifying potential issues before product release reduces the risk of recalls, reputational damage, and financial losses.

How Does Eurolabs Cable Harness Testing Service Work?

Eurolabs comprehensive Cable Harness Testing service includes

Initial Consultation Discuss your cable harness testing requirements with our expert team to understand your specific needs.

Testing Protocol Development Our experts will develop a tailored testing plan that meets industry standards and regulations.

Sampling and Preparation Well ensure the cable harness samples are properly prepared for testing, following strict quality control procedures.

Thorough Testing Our state-of-the-art equipment and expert technicians will conduct rigorous testing to evaluate electrical continuity, insulation resistance, temperature range, vibration resistance, and more.

Detailed Reporting Well provide a comprehensive report outlining test results, highlighting any issues or areas for improvement.

Frequently Asked Questions about Cable Harness Testing

Q What types of products require Cable Harness Testing?

A Products that contain cable harnesses, such as vehicles, medical devices, industrial machinery, and consumer electronics.

Q Why is Cable Harness Testing essential for businesses?

A Ensures product reliability, reduces warranty claims, enhances safety features, increases efficiency, ensures compliance with regulations, and provides a competitive advantage.

Q What parameters are typically tested in Cable Harness Testing?

A Electrical continuity, insulation resistance, temperature range, vibration resistance, and more.

Q Can Eurolabs Cable Harness Testing service be customized to meet specific requirements?

A Yes, our expert team will develop a tailored testing plan that meets industry standards and regulations.

Q What kind of equipment does Eurolab use for Cable Harness Testing?

A We utilize state-of-the-art equipment to ensure accurate and reliable test results.

Conclusion

In todays fast-paced world, manufacturers must prioritize product reliability and safety above all else. By partnering with Eurolabs Cable Harness Testing service, businesses can unlock the full potential of their products while minimizing risks associated with electrical failures, recalls, and reputational damage. Dont risk your reputation on faulty cable harnesses contact us today to learn more about our comprehensive laboratory services.

Unlocking Reliability The Critical Importance of Cable Harness Testing in Todays Competitive Market

Eurolab is committed to helping businesses succeed by providing expert testing solutions that ensure product reliability and safety. With our state-of-the-art equipment, tailored testing plans, and expert technicians, were the perfect partner for manufacturers looking to improve their products and gain a competitive edge.

At Eurolab, we understand the importance of Cable Harness Testing in todays market. Our comprehensive laboratory services enable manufacturers to

Identify potential issues early on

Ensure compliance with industry standards and regulations

Reduce warranty claims and associated costs

Enhance safety features and user experience

Increase efficiency and productivity

Dont wait until its too late contact us today to learn more about our Cable Harness Testing service and take the first step towards unlocking your products full potential.