The Importance of Capacity Verification Why Your Business Needs It to Stay Ahead

In todays fast-paced and highly competitive business landscape, companies are constantly striving to optimize their operations and improve efficiency. One crucial aspect that often gets overlooked is the verification of laboratory equipment capacity. This critical process, known as Capacity Verification, ensures that your laboratory equipment is functioning within its optimal parameters, providing accurate results, and maintaining regulatory compliance.

At Eurolab, we specialize in providing top-notch laboratory services, including Capacity Verification. Our team of expert technicians and scientists understand the significance of this process and are dedicated to helping businesses like yours navigate the complexities of laboratory testing.

In this article, well delve into the world of Capacity Verification, exploring its benefits, importance, and why its an essential service for your business. Whether youre a seasoned laboratory professional or just starting out, our comprehensive guide will walk you through the ins and outs of Capacity Verification and demonstrate how Eurolab can help you achieve peak performance.

What is Capacity Verification?

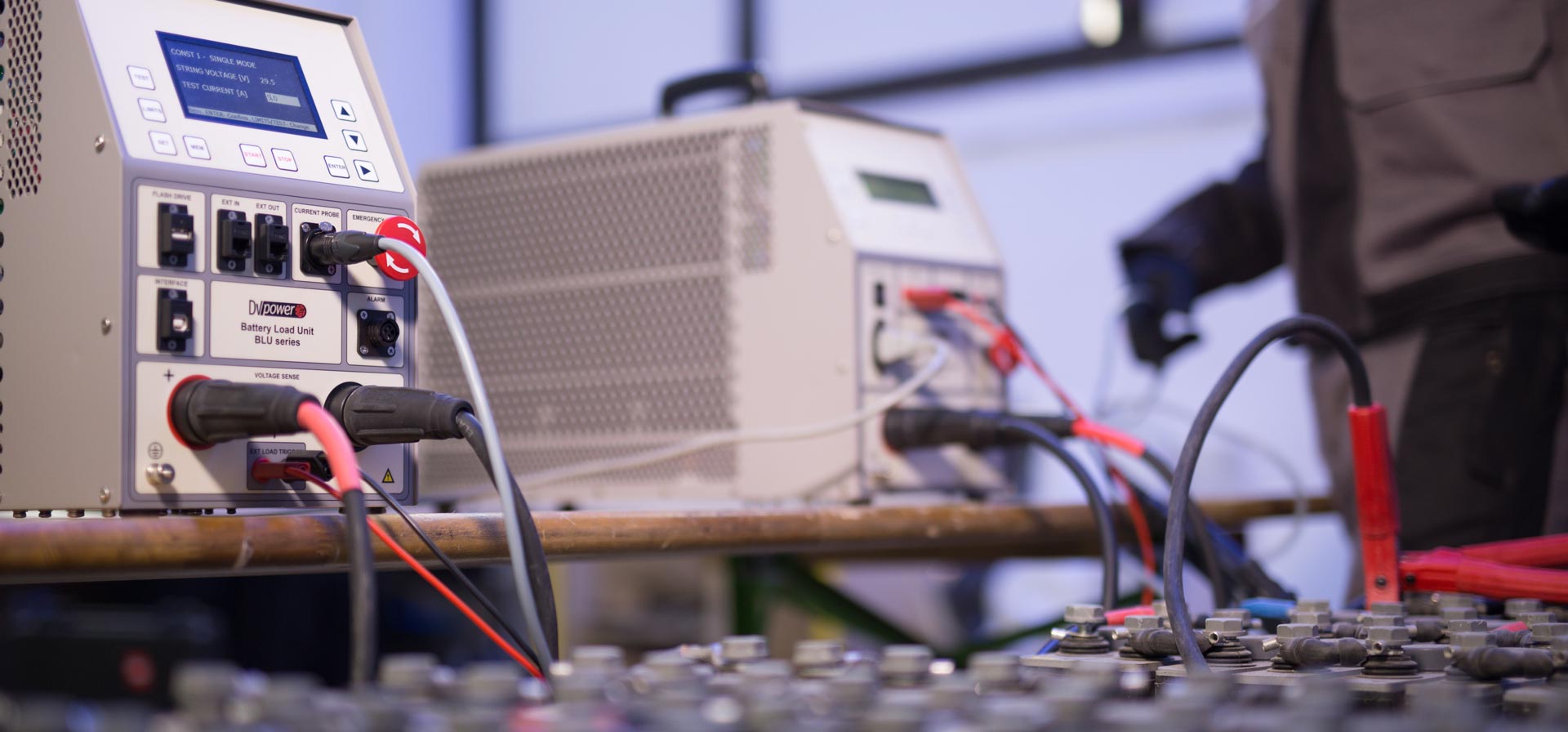

Capacity Verification is a laboratory service that ensures your equipment is operating at its maximum capacity. This involves testing the performance of various instruments, such as spectrometers, chromatography systems, and mass analyzers, to verify their accuracy, precision, and throughput. By conducting regular Capacity Verifications, you can

Ensure regulatory compliance

Maintain instrument calibration

Optimize workflow efficiency

Improve data quality

Advantages of Using Capacity Verification Services

The benefits of using Capacity Verification services are numerous and far-reaching. Here are just a few of the key advantages of partnering with Eurolab

Improved Data Quality Regular Capacity Verifications ensure that your equipment is producing accurate results, reducing errors and enhancing data integrity.

Enhanced Regulatory Compliance By verifying instrument capacity, you can demonstrate compliance with industry standards and regulations, minimizing the risk of non-compliance penalties.

Increased Efficiency Optimized instrument performance enables faster turnaround times, improved workflow efficiency, and reduced costs associated with equipment maintenance and replacement.

Cost Savings Regular Capacity Verifications can help prevent costly equipment failures, reducing downtime and minimizing expenses related to repair or replacement.

Extended Equipment Life Properly maintained instruments last longer, reducing the need for premature replacements and extending your laboratorys overall lifespan.

Accreditation and Certification By maintaining a record of Capacity Verifications, you can demonstrate to accreditation bodies that your equipment is compliant with industry standards.

How Does Eurolabs Capacity Verification Service Work?

Our expert technicians will work closely with your team to develop a tailored Capacity Verification program that meets the unique needs of your laboratory. This involves

Instrument Selection Well identify the relevant instruments for testing and create a customized schedule for Capacity Verification.

Preparation and Testing Our skilled technicians will prepare each instrument for testing, conducting thorough calibrations and performance verifications as needed.

Data Analysis Well collect and analyze data from each test, providing detailed reports on instrument performance, accuracy, and precision.

Reporting and Recommendations After completing the Capacity Verification process, well provide a comprehensive report outlining our findings and recommendations for optimizing instrument performance.

Frequently Asked Questions (FAQs)

Weve compiled a list of commonly asked questions about Capacity Verification to help you better understand this critical laboratory service

What is the purpose of Capacity Verification?

How often should I conduct Capacity Verifications on my laboratory equipment?

Which types of instruments require Capacity Verification?

Can I perform Capacity Verifications in-house, or do I need to outsource to a third-party provider like Eurolab?

What are the costs associated with Capacity Verification services?

Conclusion

Capacity Verification is an essential service for businesses that rely on laboratory equipment to ensure accuracy, precision, and regulatory compliance. By partnering with Eurolabs expert team, you can rest assured that your instruments are operating at their maximum capacity, reducing errors, improving data quality, and minimizing costs.

Whether youre seeking to optimize workflow efficiency, improve data integrity, or maintain regulatory compliance, our comprehensive Capacity Verification service is designed to meet the unique needs of your laboratory. Contact us today to learn more about how Eurolab can help you achieve peak performance in your laboratory.