Coating thickness measurement using X-ray fluorescence

Accurate Coating Thickness Measurement Unlocking Business Efficiency with X-ray Fluorescence

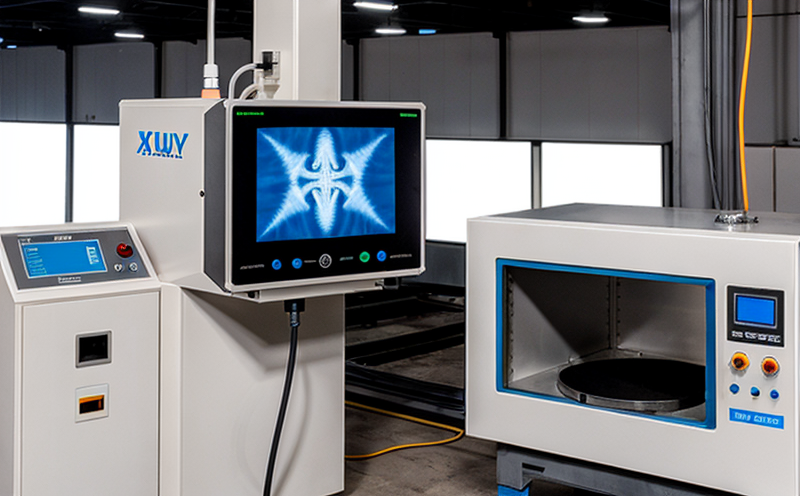

In todays fast-paced industrial landscape, precision and reliability are crucial for businesses to stay ahead of the competition. One critical aspect that often gets overlooked is the measurement of coating thickness, which can significantly impact product quality, performance, and overall operational efficiency. Coating thickness measurement using X-ray fluorescence (XRF) is a laboratory service provided by Eurolab that enables companies to accurately determine the thickness of coatings on various materials with unprecedented precision.

What is Coating Thickness Measurement using X-ray Fluorescence?

X-ray fluorescence (XRF) is an advanced analytical technique used to measure the elemental composition and coating thickness of materials. In the context of coating thickness measurement, XRF uses a beam of high-energy X-rays to excite the atoms in the materials surface layer. As these excited atoms return to their ground state, they emit secondary X-rays that are characteristic of the elements present in the sample. By analyzing these emitted X-rays, scientists can accurately determine the thickness and composition of the coating.

Why is Coating Thickness Measurement using X-ray Fluorescence Essential for Businesses?

The significance of accurate coating thickness measurement cannot be overstated. Here are some compelling reasons why businesses need to adopt this laboratory service

Enhanced Product Quality Accurate coating thickness measurements enable manufacturers to ensure that their products meet the required specifications, resulting in higher-quality outputs.

Improved Operational Efficiency By eliminating the need for destructive testing methods, XRF-based coating thickness measurement saves time and reduces costs associated with material wastage and re-work.

Increased Reliability The high precision of XRF-based measurements ensures consistent results, reducing the likelihood of errors and improving overall product reliability.

Advantages of Coating Thickness Measurement using X-ray Fluorescence

Here are some key benefits of using Eurolabs XRF-based coating thickness measurement service

Non-Destructive Testing XRF is a non-invasive technique that does not damage the sample, making it an ideal choice for testing sensitive materials.

High Precision XRF offers accuracy levels of up to 1 or better, depending on the specific application and instrument used.

Rapid Analysis XRF-based measurements are significantly faster than traditional methods, enabling businesses to accelerate their production processes.

Multi-Element Analysis XRF can detect multiple elements simultaneously, providing a comprehensive understanding of the materials composition.

Key Applications for Coating Thickness Measurement using X-ray Fluorescence

Eurolabs XRF-based coating thickness measurement service has a wide range of applications across various industries, including

Automotive and Aerospace Accurate coating thickness measurements are critical in ensuring the quality and performance of vehicle coatings and aerospace components.

Electronics and Semiconductors XRF is used to measure the thickness of thin films and coatings on electronic components, such as printed circuit boards and semiconductor wafers.

Medical Devices Coating thickness measurement using XRF ensures that medical devices meet strict regulatory requirements for biocompatibility and performance.

Frequently Asked Questions (FAQs)

What types of materials can be analyzed using XRF?

XRF can analyze a wide range of materials, including metals, alloys, ceramics, glasses, and polymers.

How does XRF compare to other coating thickness measurement techniques?

XRF offers higher accuracy and precision compared to traditional methods, such as eddy current testing or visual inspection.

Can XRF be used for coatings thicker than 100 microns?

Yes, XRF can measure coatings of any thickness, including those exceeding 100 microns.

How long does the analysis process take?

XRF-based measurements are typically completed within minutes, depending on the instrument and sample complexity.

Conclusion

Coating thickness measurement using X-ray fluorescence is a game-changing laboratory service that provides unparalleled accuracy and precision in determining the thickness of coatings on various materials. By adopting this technology, businesses can enhance product quality, improve operational efficiency, and increase reliability. Eurolabs expertise and state-of-the-art equipment ensure that customers receive high-quality results with minimal turnaround time.

Dont compromise on your businesss success due to inaccurate coating thickness measurements. Partner with Eurolab today to experience the benefits of XRF-based coating thickness measurement for yourself.