Cohesion balance in high-performance adhesives

Achieving Optimal Cohesion Balance in High-Performance Adhesives Unlocking Enhanced Productivity and Efficiency

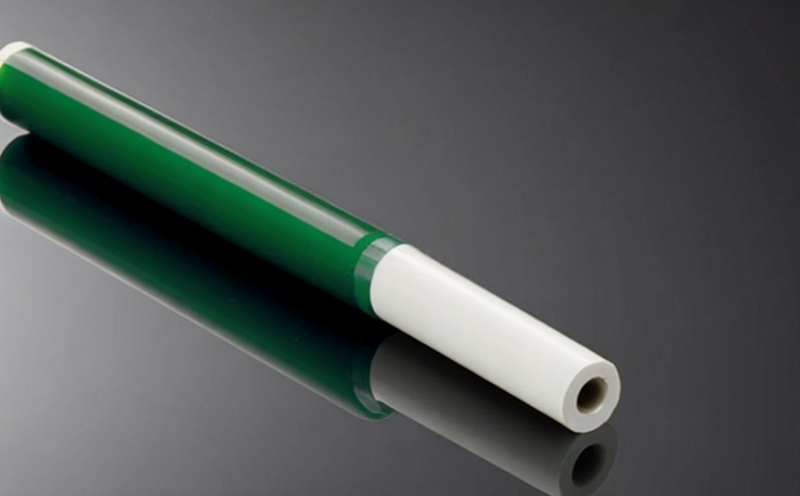

In the world of advanced materials science, cohesion balance plays a critical role in ensuring the exceptional performance of high-performance adhesives. These specialized adhesives are designed to bond even the most challenging materials with unparalleled strength and durability. However, achieving optimal cohesion balance is no easy feat, requiring precise control over the adhesives molecular structure and chemical composition.

At Eurolab, our team of expert scientists and engineers have dedicated themselves to developing cutting-edge laboratory services that cater to the needs of businesses seeking to optimize their adhesive performance. One such service is our Cohesion Balance analysis for high-performance adhesives. This comprehensive evaluation helps manufacturers refine their formulations, ensuring that their products meet the highest standards of quality and reliability.

What is Cohesion Balance in High-Performance Adhesives?

Cohesion balance refers to the equilibrium between an adhesives internal bonding forces (cohesion) and its external bonding forces (adhesion). In high-performance adhesives, achieving a balanced cohesion allows for optimal bonding performance, while an imbalance can lead to reduced strength, durability, and overall effectiveness.

Why is Cohesion Balance Essential for Businesses?

In todays competitive market, businesses that rely on high-performance adhesives to manufacture products require exceptional bonding performance. A well-balanced cohesion ensures that

Optimized Bonding Strength Adheres materials with unparalleled bond strength, reducing the risk of product failure and associated costs.

Enhanced Durability Extends product lifespan by minimizing the impact of environmental factors such as temperature fluctuations and moisture exposure.

Increased Efficiency Reduces processing times and energy consumption, resulting in lower production costs and improved productivity.

Improved Safety Ensures products meet regulatory requirements and are free from potential hazards, such as toxic chemical leachates.

Benefits of Using Cohesion Balance Analysis

By leveraging our Cohesion Balance analysis service, manufacturers can

Refine Formulations Identify areas for improvement in their adhesive formulations, allowing them to create tailored solutions that meet specific application demands.

Optimize Manufacturing Processes Adjust production parameters and schedules to accommodate optimized adhesive performance, reducing waste and energy consumption.

Enhance Product Performance Achieve products with improved bonding strength, durability, and resistance to environmental stressors.

Gain Competitive Advantage Differentiate their products from competitors by demonstrating exceptional bonding capabilities.

How Does Cohesion Balance Analysis Work?

Our comprehensive analysis involves

Sample Preparation Clients provide high-performance adhesive samples for evaluation.

Instrumentation We employ state-of-the-art equipment, such as atomic force microscopes and spectroscopy tools, to analyze the adhesives molecular structure and chemical composition.

Data Analysis Our team of experts interprets the data to identify areas where cohesion balance can be improved.

Formulation Optimization Based on the analysis results, we recommend tailored formulation adjustments for optimal cohesion balance.

QA Section

Q What types of high-performance adhesives can benefit from Cohesion Balance analysis?

A Our service is suitable for a wide range of high-performance adhesives, including epoxy, polyurethane, acrylic, and silicone-based products.

Q How long does the analysis process take?

A The duration depends on the complexity of the adhesive formulation and the number of samples submitted. Typically, results are available within 2-4 weeks.

Q Can Cohesion Balance analysis help with troubleshooting adhesive performance issues?

A Yes! Our analysis can identify areas for improvement in existing formulations, helping manufacturers troubleshoot performance issues and optimize their products.

Q What kind of data support can I expect from the analysis results?

A We provide detailed reports that include graphical representations of the adhesives molecular structure, chemical composition, and cohesion balance metrics. This information enables clients to refine their formulations and make informed decisions about product development.

Conclusion

In todays fast-paced manufacturing environment, businesses rely on high-performance adhesives to produce products with exceptional bonding capabilities. Achieving optimal cohesion balance is crucial for ensuring these products meet the highest standards of quality and reliability. By leveraging Eurolabs comprehensive Cohesion Balance analysis service, manufacturers can refine their adhesive formulations, optimize manufacturing processes, and gain a competitive advantage in the market.

Dont compromise on product performance trust Eurolab to provide expert guidance and cutting-edge laboratory services for your high-performance adhesive needs. Contact us today to learn more about our Cohesion Balance analysis and how it can help take your products to the next level!