Component fatigue testing to simulate long-term usage of vehicle parts over time

Simulating Long-Term Usage Unlocking the Secrets of Component Fatigue Testing with Eurolab

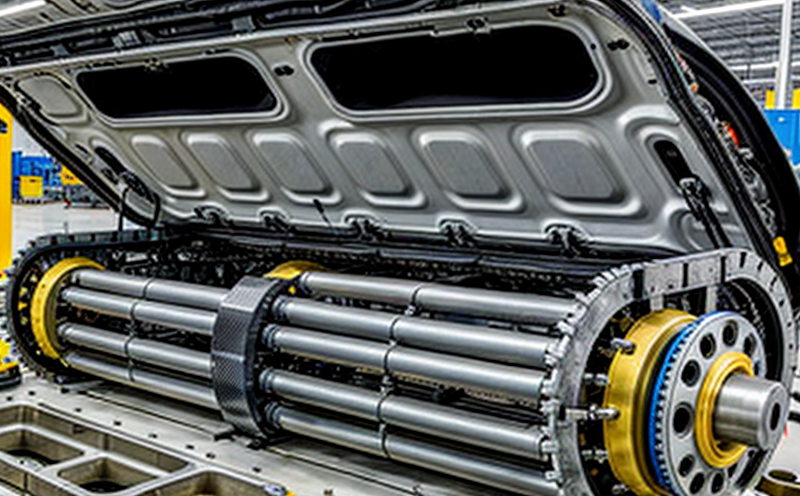

In todays fast-paced automotive industry, manufacturers are constantly seeking innovative ways to improve vehicle performance, reliability, and safety. One crucial aspect that often goes unnoticed is the long-term durability of critical components. Over time, repeated stress and strain can lead to wear and tear, potentially causing catastrophic failures on the road. This is where Component Fatigue Testing comes in a sophisticated laboratory service provided by Eurolab that simulates real-world usage conditions to predict component lifespan.

In this comprehensive article, well delve into the world of Component Fatigue Testing, exploring its benefits, applications, and the advantages of partnering with Eurolab for accelerated testing solutions. By the end of this journey, youll understand why this laboratory service is an indispensable tool for businesses aiming to ensure the longevity and reliability of their products.

What is Component Fatigue Testing?

Component Fatigue Testing is a laboratory-based method that subject critical vehicle components to controlled stress cycles, replicating real-world usage patterns. This simulation process helps identify potential weaknesses and predict component lifespan under various operating conditions. By analyzing test results, manufacturers can optimize design improvements, enhance performance, and reduce the likelihood of costly failures.

Why is Component Fatigue Testing Essential for Businesses?

Partnering with Eurolab to perform Component Fatigue Testing provides numerous benefits for businesses

Improved Product Reliability By simulating long-term usage conditions, you can pinpoint potential weaknesses and optimize component design.

Enhanced Performance Our testing services help fine-tune components for optimal performance under various operating conditions.

Reduced Risk of Failures With a deeper understanding of component lifespan, youll minimize the risk of costly failures on the road.

Compliance with Industry Regulations Component Fatigue Testing ensures your products meet or exceed industry standards and regulations.

Key Benefits of Component Fatigue Testing

Here are some key benefits of using Eurolabs Component Fatigue Testing services

Cost Savings By identifying potential issues early, you can avoid costly redesigns, retesting, and manufacturing delays.

Increased Efficiency Our expert team provides detailed reports and recommendations to streamline your design process.

Competitive Advantage Partnering with a renowned laboratory like Eurolab sets your business apart from competitors in the industry.

How Does Component Fatigue Testing Work?

Our state-of-the-art facility is equipped with cutting-edge equipment, allowing us to simulate real-world usage conditions for various vehicle components. Our expert engineers perform the following steps

Component Preparation We carefully prepare and clean each component according to your specifications.

Test Setup Our team sets up the testing equipment to replicate the desired operating conditions.

Testing and Data Collection The component is subjected to controlled stress cycles, and data is collected in real-time.

Data Analysis Our expert engineers analyze test results to identify potential weaknesses and predict component lifespan.

QA Section Your Component Fatigue Testing Questions Answered

Q What types of components can be tested using this method?

A We test a wide range of vehicle components, including engines, transmissions, brakes, suspension systems, and more.

Q How long does the testing process typically take?

A The duration of testing varies depending on the component type and desired simulation parameters. Our team will work closely with you to determine the optimal testing schedule.

Q Can I observe or participate in the testing process?

A While we encourage collaboration, our facility is designed for safety reasons. However, our expert engineers will provide regular updates and discuss test results with you during scheduled meetings.

Q How do you ensure data accuracy and reliability?

A Our laboratory adheres to strict quality control protocols, ensuring that all testing equipment is calibrated regularly and operated by experienced personnel.

Conclusion

In the fast-paced world of automotive manufacturing, businesses must continually adapt to evolving industry standards. By leveraging Eurolabs Component Fatigue Testing services, youll gain a competitive edge in developing reliable, high-performance products. Dont let uncertainty about component lifespan hold you back partner with us today and unlock the secrets of long-term usage conditions.

At Eurolab, we pride ourselves on delivering expert guidance and support throughout your testing journey. Our team is committed to helping businesses like yours achieve optimal product reliability, performance, and safety. Join us in shaping a safer, more efficient future for the automotive industry.