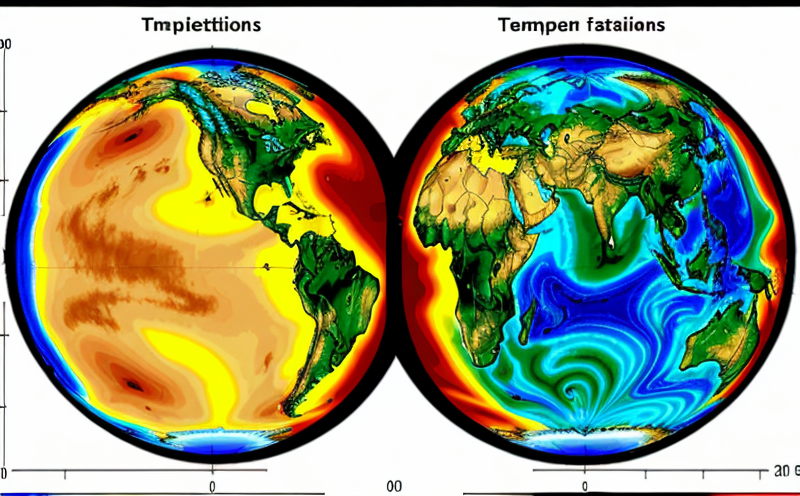

Distortion Due to Temperature Variations

Understanding Distortion Due to Temperature Variations A Crucial Service for Businesses

As a manufacturer or supplier of materials, youre likely no stranger to the importance of quality control and assurance in your production processes. However, theres one critical factor that often gets overlooked, yet has significant implications for the integrity of your products temperature variations. Distortion due to temperature variations is a laboratory service provided by Eurolab that helps businesses like yours mitigate the effects of temperature fluctuations on their materials.

What is Distortion Due to Temperature Variations?

Distortion due to temperature variations refers to the physical changes that occur in materials when they are exposed to extreme temperatures. These changes can manifest as dimensional shifts, warping, or cracking, compromising the structural integrity and performance of your products. In industries such as aerospace, automotive, construction, and manufacturing, distortion due to temperature variations is a major concern.

Why is Distortion Due to Temperature Variations Essential for Businesses?

In todays competitive market, companies cannot afford to produce subpar products that may fail to meet quality standards or specifications. Distortion due to temperature variations can lead to costly recalls, rework, and even litigation. By understanding the effects of temperature on your materials, you can

Ensure compliance with industry regulations Many industries have specific standards for material testing and certification. Eurolabs distortion due to temperature variations service helps ensure that your products meet these requirements.

Reduce production costs Avoiding costly rework and recalls saves time and resources, allowing you to focus on producing high-quality products efficiently.

Enhance product performance By understanding how temperature affects your materials, you can optimize their properties and behavior under various conditions.

Advantages of Using Distortion Due to Temperature Variations

Eurolabs distortion due to temperature variations service offers numerous benefits for businesses

Key Benefits

Accurate Material Testing Our laboratory uses state-of-the-art equipment and expert technicians to perform precise testing, providing you with reliable data on material behavior under different temperatures.

Customized Solutions We tailor our services to meet your specific needs, whether youre looking for standard or non-standard testing protocols.

Rapid Turnaround Time Our experienced team ensures prompt results, allowing you to make informed decisions quickly and get back to production.

Expert Consultation Our team of experts provides valuable insights into material behavior, helping you optimize your products performance.

Advantages for Specific Industries

Distortion due to temperature variations affects various industries differently. Here are some specific benefits for a few key sectors

Aerospace Industry Ensure compliance with stringent regulations and standards for materials used in aircraft construction.

Automotive Industry Test the durability and performance of materials under extreme temperatures, ensuring safe and reliable operation on the road.

Construction Industry Verify that building materials can withstand temperature fluctuations without compromising their structural integrity.

Additional Benefits

Eurolabs distortion due to temperature variations service also offers

Peace of Mind Knowing that your products meet quality standards gives you confidence in their performance and reliability.

Competitive Edge By prioritizing material testing, you can differentiate yourself from competitors and establish a reputation for excellence.

Frequently Asked Questions

Q What types of materials are tested for distortion due to temperature variations?

A Our laboratory tests various materials, including metals, alloys, plastics, composites, and ceramics.

Q How do I prepare my samples for testing?

A Contact our team to discuss your specific needs and receive guidance on sample preparation.