Drop Simulation Testing for Cosmetic Packaging During Transportation

Protecting Your Brands Reputation The Importance of Drop Simulation Testing for Cosmetic Packaging During Transportation

In the cosmetics industry, packaging is not just a vessel for products; it is an essential component that significantly impacts consumer perception and ultimately, sales. A damaged package can lead to product leakage, contamination, or even complete destruction, resulting in financial losses, loss of customer trust, and damage to your brands reputation. To mitigate these risks, Eurolab offers Drop Simulation Testing for Cosmetic Packaging During Transportation - a cutting-edge laboratory service that simulates real-world transportation conditions to assess the durability of cosmetic packaging.

The Risks of Damaged Packaging

Cosmetic products are fragile, high-value items that require specialized handling and packaging to prevent damage during transportation. A single incident of damaged packaging can lead to significant losses for your business. According to a study by the Packaging Digest, packaging damage costs businesses in the United States alone an estimated 45 billion annually.

What is Drop Simulation Testing?

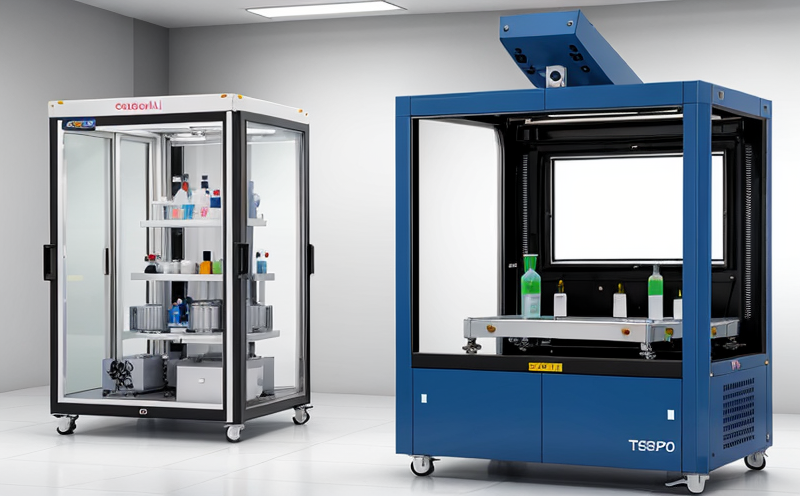

Drop Simulation Testing is a laboratory-based testing method that mimics real-world transportation conditions to assess the robustness of cosmetic packaging under various scenarios. Eurolabs expert technicians use specialized equipment to simulate drops from different heights, angles, and orientations to replicate potential transportation-related damage. This testing allows you to identify weaknesses in your packaging design before it reaches customers.

Advantages of Drop Simulation Testing for Cosmetic Packaging During Transportation

Our Drop Simulation Testing service offers numerous benefits that can help protect your brands reputation and ensure compliance with regulatory requirements

Reduced Product Damage By identifying potential weaknesses in packaging, you can redesign or improve existing designs to minimize damage during transportation.

Cost Savings A single incident of damaged packaging can lead to significant costs. Our testing helps you avoid these expenses by identifying areas for improvement before production begins.

Compliance with Regulatory Requirements Cosmetic packaging must comply with various regulations, including the International Organization for Standardization (ISO) and the European Unions Good Manufacturing Practices (GMP). Our testing ensures that your packaging meets these standards.

Improved Brand Reputation By demonstrating a commitment to product safety and quality, you can build trust with customers and maintain a positive brand image.

Key Benefits of Drop Simulation Testing

Our service provides several key benefits that set us apart from other laboratory services

Customized Testing Programs We work closely with you to design customized testing programs tailored to your specific packaging needs.

Advanced Equipment Our state-of-the-art equipment allows for precise simulation of real-world transportation conditions, ensuring accurate and reliable results.

Expert Analysis and Reporting Our experienced technicians provide detailed analysis and reporting on test results, helping you identify areas for improvement.

Compliance with International Standards We ensure that our testing procedures comply with international standards, including ISO 6344 (Plastics Urethane Impact Resistance) and ISO 10893 (Rubber Determination of the impact resistance).

Frequently Asked Questions

Q What types of packaging can be tested using Drop Simulation Testing?

A Our service is suitable for a wide range of cosmetic packaging, including glass bottles, plastic containers, and tubes.

Q How long does the testing process take?

A The duration of our testing services varies depending on the scope of the project. We work closely with you to ensure that testing is completed efficiently and effectively.

Q Can I witness the testing in person?

A Yes, we welcome observers during testing. Our experienced technicians will guide you through the process and provide explanations of the testing procedures.

Q What are the benefits of using Drop Simulation Testing compared to other laboratory services?

A Our service provides a unique combination of customized testing programs, advanced equipment, expert analysis, and compliance with international standards.

Conclusion

Protecting your brands reputation is crucial in the cosmetics industry. Eurolabs Drop Simulation Testing for Cosmetic Packaging During Transportation provides a comprehensive solution to identify potential weaknesses in packaging design before it reaches customers. By choosing our service, you can reduce product damage, save costs, ensure compliance with regulatory requirements, and maintain a positive brand image.

Dont risk your businesss reputation; choose the most reliable and advanced laboratory testing service available. Contact Eurolab today to learn more about how Drop Simulation Testing for Cosmetic Packaging During Transportation can benefit your company.