Dynamic balancing of electric motors and pumps

Dynamic Balancing of Electric Motors and Pumps Unlocking Efficiency and Reliability for Your Business

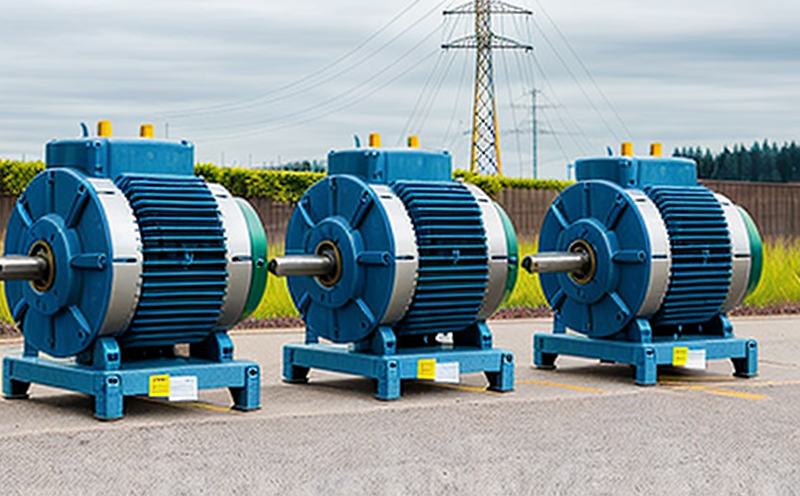

In the world of industrial machinery, electric motors and pumps are the backbone of many operations. They power everything from manufacturing equipment to water treatment facilities, and their reliability is crucial to maintaining productivity and efficiency. However, even with proper maintenance, these critical components can suffer from imbalance, leading to reduced performance, increased energy consumption, and costly downtime. This is where dynamic balancing of electric motors and pumps comes in a laboratory service that ensures your machinery operates at peak performance.

What is Dynamic Balancing of Electric Motors and Pumps?

Dynamic balancing is the process of identifying and correcting any imbalance or vibration in electric motors and pumps. When an engine or pump is out of balance, it can lead to premature wear on bearings, seals, and other components, causing costly repairs and lost production time. By using advanced measurement techniques and equipment, dynamic balancing services can detect even slight imbalances, allowing for prompt correction and extending the lifespan of your machinery.

The Importance of Dynamic Balancing

In todays fast-paced business environment, every minute counts. Downtime due to equipment failure or maintenance can have a significant impact on productivity and profitability. By investing in regular dynamic balancing services, businesses can

Reduce Energy Consumption Imbalanced motors and pumps consume more energy than necessary, leading to higher operating costs and increased carbon emissions.

Prolong Equipment Lifespan Correcting imbalances prevents excessive wear and tear on components, extending the life of your machinery and reducing maintenance needs.

Minimize Downtime Regular balancing ensures that equipment operates smoothly, minimizing the risk of unexpected shutdowns and costly repairs.

Improve Performance Balanced motors and pumps operate more efficiently, leading to improved product quality and increased productivity.

Key Benefits of Dynamic Balancing

Here are some key benefits of dynamic balancing services

Advantages for Businesses

Reduced energy consumption

Extended equipment lifespan

Minimized downtime

Improved performance

Enhanced productivity

Increased profitability

Advantages for Maintenance Teams

Simplified maintenance scheduling

Early detection of potential issues

Reduced risk of equipment failure

Improved overall machine reliability

Advantages for Environmentally Conscious Businesses

Lower carbon emissions

Reduced energy consumption

Extended lifespan of components

Frequently Asked Questions

Here are some common questions about dynamic balancing services

Q What is the process for dynamic balancing?

A The process involves collecting vibration data from your equipment, analyzing it using advanced software, and making any necessary adjustments to achieve balance.

Q How often should I have my motors and pumps dynamically balanced?

A Regular maintenance schedules can vary depending on usage, but we recommend annual balancing for most industrial applications.

Q Can dynamic balancing improve the performance of my equipment?

A Yes! By correcting imbalances, you can expect improved energy efficiency, reduced vibration, and extended lifespan of your components.

Why Choose Eurolab for Dynamic Balancing Services

At Eurolab, we understand the importance of reliable machinery in industrial operations. Our experienced technicians use state-of-the-art equipment to provide accurate measurements and expert analysis, ensuring that your motors and pumps operate at peak performance. By choosing us for dynamic balancing services, you can

Trust our expertise Our team has extensive experience with a wide range of industrial equipment.

Reliable results We use only the latest technology and software to ensure accurate measurements and precise balancing.

Efficient turnaround times We work efficiently to minimize downtime and get your equipment back online quickly.

Conclusion

In todays competitive business environment, every aspect of operations counts. Dynamic balancing of electric motors and pumps is a critical maintenance service that can make all the difference in ensuring efficiency, reliability, and productivity. By investing in regular balancing services with Eurolab, businesses can reduce energy consumption, prolong equipment lifespan, minimize downtime, and improve performance. Dont let imbalances hinder your operations contact us today to schedule your dynamic balancing service!