Effect of repeated mechanical stress on pilling resistance

The Impact of Repeated Mechanical Stress on Pilling Resistance Why Businesses Need This Crucial Laboratory Service

In todays fast-paced business environment, product quality and durability are more crucial than ever. One critical aspect of ensuring the longevity of your products is understanding how they perform under repeated mechanical stress. Pilling resistance, in particular, is a vital property that can make or break a companys reputation. At Eurolab, our team of experts offers a cutting-edge laboratory service that helps businesses like yours optimize their products performance and enhance customer satisfaction.

What is Effect of Repeated Mechanical Stress on Pilling Resistance?

Pilling resistance refers to a materials ability to withstand mechanical stress without developing pills or fibers, which can lead to a decrease in product quality and lifespan. When subjected to repeated mechanical stress, materials often undergo a process called pilling, where fibers break off and form small balls of fluff. This phenomenon is particularly prevalent in textiles, but also affects other materials like plastics, composites, and more.

Why is Effect of Repeated Mechanical Stress on Pilling Resistance Essential for Businesses?

In the world of product development and manufacturing, understanding how your products perform under repeated mechanical stress is vital for several reasons

Improved Product Quality By conducting pilling resistance tests, you can identify areas where your materials or products may be prone to damage. This allows you to make informed decisions about material selection, production processes, and quality control measures.

Enhanced Customer Satisfaction Products that withstand repeated mechanical stress are more likely to meet customer expectations, leading to increased satisfaction and loyalty. When customers know they can rely on your products, they become repeat buyers and advocates for your brand.

Competitive Advantage Companies that prioritize pilling resistance testing differentiate themselves from competitors by showcasing their commitment to quality and durability. This sets them apart in the market and establishes a strong reputation for excellence.

Reduced Waste and Costs By identifying potential weaknesses early on, you can minimize product recalls, returns, and replacements. This, in turn, reduces waste, saves resources, and contributes to a more sustainable supply chain.

Benefits of Using Eurolabs Laboratory Service

At Eurolab, we provide a comprehensive laboratory service that includes

Customized Testing Protocols Our team works closely with you to develop tailored testing protocols that cater to your specific needs and requirements.

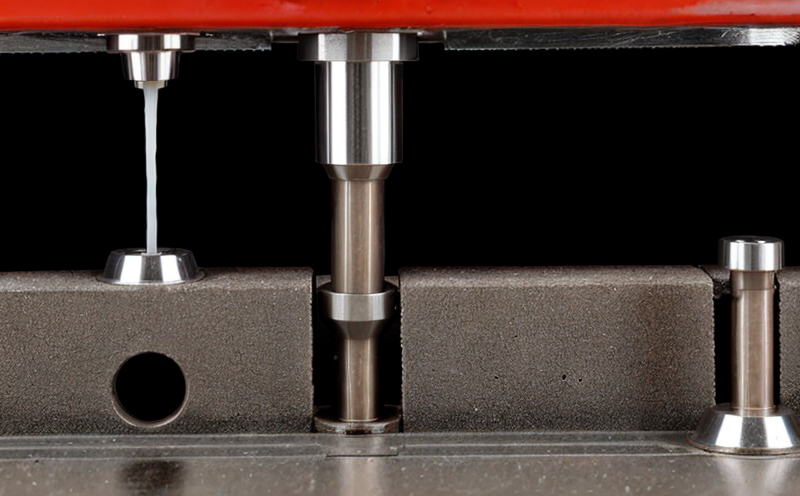

State-of-the-Art Equipment We utilize cutting-edge equipment and technology to ensure accurate and reliable results.

Expert Analysis Our experienced analysts provide in-depth analysis and interpretation of test data, helping you understand the implications for your products.

Prompt Reporting We deliver detailed reports that meet international standards, providing a clear picture of your materials performance under repeated mechanical stress.

QA Section

Q What types of materials can be tested for pilling resistance?

A Our laboratory service caters to a wide range of materials, including textiles, plastics, composites, and more. We work with various industries, from fashion and apparel to automotive and aerospace.

Q How do I know which testing protocol is right for my products?

A Our experts will guide you through the process, discussing your specific needs and requirements to develop a customized testing plan that suits your business goals.

Q What kind of data can I expect from the testing results?

A We provide detailed reports that include test parameters, methods used, and results. This information enables you to make informed decisions about material selection, production processes, and quality control measures.

Q Can Eurolabs laboratory service help me reduce costs associated with product failures?

A Yes! By identifying potential weaknesses early on, we can help you minimize waste, reduce recalls and returns, and save resources. This contributes to a more sustainable supply chain and enhances your bottom line.

Conclusion

In todays competitive business landscape, understanding the effect of repeated mechanical stress on pilling resistance is no longer a luxury its a necessity. By partnering with Eurolab, you can ensure that your products meet the highest standards of quality and durability, setting your company apart from competitors and driving customer satisfaction.

Dont let product failures hold you back any longer. Contact us today to learn more about our laboratory service and discover how we can help you optimize your products performance under repeated mechanical stress.