Elasticity in flexible adhesives

The Power of Elasticity in Flexible Adhesives Unlocking a Stronger Bond

In todays fast-paced manufacturing world, businesses are constantly seeking innovative ways to improve their products and stay ahead of the competition. One crucial aspect that can make all the difference is the use of elasticity in flexible adhesives. At Eurolab, we specialize in providing laboratory services that help companies like yours achieve the perfect balance between flexibility and strength.

What is Elasticity in Flexible Adhesives?

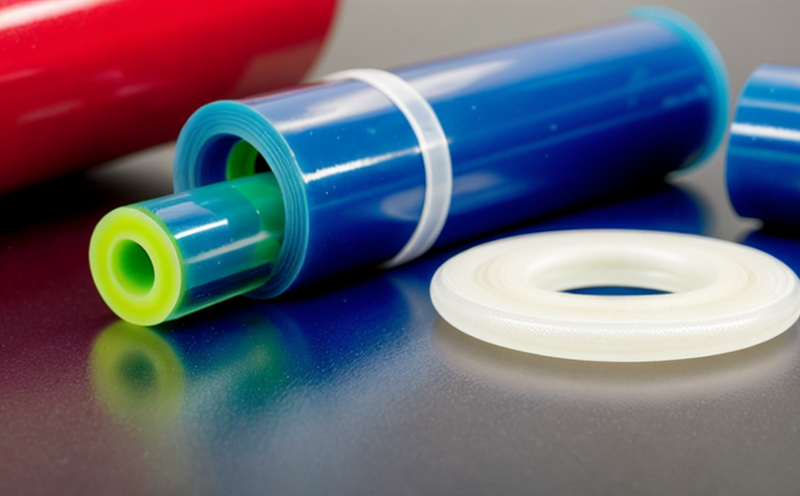

Elasticity in flexible adhesives refers to the ability of a material to return to its original shape after being stretched or deformed. This property is essential for applications where flexibility and durability are critical, such as in medical devices, automotive components, and consumer products.

Why is Elasticity Important for Businesses?

Incorporating elasticity into your flexible adhesives can have a significant impact on your businesss bottom line. Here are just a few reasons why

Improved Performance Elastic materials can withstand harsh environmental conditions, such as extreme temperatures and humidity, while maintaining their shape and adhesive properties.

Increased Durability By incorporating elasticity, you can extend the lifespan of your products, reducing the need for costly replacements and repairs.

Enhanced User Experience Flexible adhesives with high elasticity provide a better grip, making them ideal for applications where safety is paramount.

The Benefits of Elasticity in Flexible Adhesives

At Eurolab, weve seen firsthand the advantages of using elasticity in flexible adhesives. Here are just a few key benefits

Improved Adhesion Elastic materials can form stronger bonds with substrates, ensuring a secure hold even under stress.

Enhanced Flexibility Our expertise allows us to create adhesive formulations that maintain their shape and flexibility, making them perfect for applications where movement is necessary.

Resistance to Fatigue By incorporating elasticity, you can reduce the likelihood of material failure due to repetitive strain or flexing.

Increased Chemical Resistance Elastic materials are often more resistant to chemicals and solvents, reducing the risk of damage or degradation.

Applications of Elasticity in Flexible Adhesives

Our laboratory services at Eurolab cater to a wide range of industries and applications. Here are just a few examples

Medical Devices Elastic adhesives are used in medical devices, such as catheters and stents, to ensure secure bonding and minimize the risk of material failure.

Automotive Components Flexible adhesives with high elasticity are used in automotive components, such as seatbelts and airbags, to provide a safe and reliable bond.

Consumer Products Elastic materials are used in consumer products, such as shoes and electronics, to ensure durability and performance.

Frequently Asked Questions (FAQs)

At Eurolab, we understand that our clients may have questions about the benefits of elasticity in flexible adhesives. Here are some of the most common FAQs

Q What is the difference between elastic and rigid materials?

A Elastic materials can deform under stress but return to their original shape when the stress is removed. Rigid materials, on the other hand, do not deform significantly under stress.

Q How does elasticity impact the performance of flexible adhesives?

A Elasticity can improve the performance of flexible adhesives by allowing them to maintain their shape and adhesive properties even after repeated strain or flexing.

Q Can I use elastic materials in extreme temperatures?

A Yes, our laboratory services at Eurolab allow us to create adhesive formulations that perform well in a wide range of temperatures.

Get the Best Out of Your Flexible Adhesives with Eurolabs Laboratory Services

At Eurolab, were committed to helping businesses like yours achieve success through innovative and high-quality laboratory services. Our expertise in elasticity in flexible adhesives can help you

Improve Performance By incorporating elasticity into your products, you can improve their performance and durability.

Reduce Costs By reducing the need for costly replacements and repairs, you can save money and increase your bottom line.

Enhance User Experience Flexible adhesives with high elasticity provide a better grip, making them ideal for applications where safety is paramount.

Dont settle for mediocre products. Choose Eurolabs laboratory services to unlock the full potential of elasticity in flexible adhesives. Contact us today to learn more about how we can help your business thrive!