Ensuring that compressive stress does not cause cracking, warping, or other structural issues

Ensuring Compressive Stress Doesnt Cause Cracking A Crucial Service for Businesses

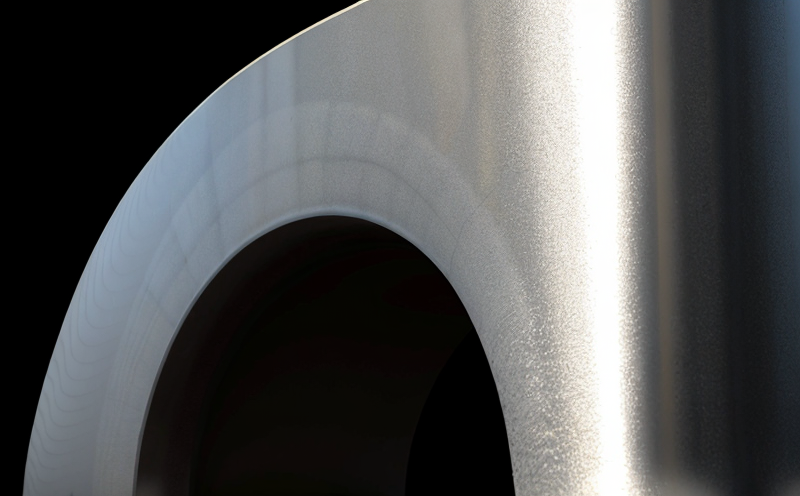

In the world of materials science and engineering, compressive stress is a fundamental concept that can have far-reaching consequences for businesses across various industries. When materials are subjected to compressive forces, they may undergo deformation, cracking, warping, or even complete failure. These structural issues can lead to costly downtime, damage to equipment, and compromised product quality, ultimately affecting the bottom line of companies.

At Eurolab, we understand the importance of ensuring that compressive stress does not cause cracking, warping, or other structural issues in materials. Our laboratory service is specifically designed to help businesses like yours mitigate these risks and maintain material integrity. In this article, well delve into the details of our Ensuring Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues service and highlight its key benefits.

What Is Ensuring Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues?

This laboratory service involves a comprehensive evaluation of materials to assess their resistance to compressive stress. Our team of experts uses state-of-the-art equipment and techniques to simulate real-world conditions and analyze the behavior of materials under compressive forces.

Through our Ensuring Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues service, we can identify potential weaknesses in materials and provide recommendations for mitigating these risks. This includes determining the optimal material properties, processing conditions, and design specifications to ensure that materials perform as expected under compressive stress.

Advantages of Using Ensuring Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues

Our laboratory service offers numerous benefits for businesses across various industries, including

Improved Material Integrity By evaluating material properties and behavior under compressive stress, we can help ensure that materials meet the required specifications and standards.

Reduced Risk of Failure Identifying potential weaknesses in materials enables businesses to take proactive measures to prevent failure, minimizing downtime and associated costs.

Increased Efficiency With our expertise, companies can optimize material selection, processing conditions, and design specifications, streamlining their operations and reducing waste.

Enhanced Product Quality By ensuring that materials perform as expected under compressive stress, businesses can maintain product quality, consistency, and reliability.

Compliance with Regulations Our laboratory service helps ensure compliance with industry-specific regulations and standards related to material properties and performance.

Key Benefits of Ensuring Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues

Cost Savings By preventing material failure and minimizing downtime, businesses can save significant amounts on maintenance, repair, and replacement costs.

Increased Product Lifespan With materials that meet the required specifications, companies can extend product lifespan, reducing the need for frequent replacements.

Improved Customer Satisfaction Ensuring that products perform as expected under compressive stress leads to higher customer satisfaction rates and reduced returns or complaints.

Competitive Advantage By prioritizing material integrity and performance, businesses can differentiate themselves from competitors and establish a reputation for quality and reliability.

How Does Eurolab Ensure Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues?

Our Ensuring Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues service involves the following steps

Material Characterization We evaluate material properties, such as strength, modulus of elasticity, and Poissons ratio, to understand their behavior under compressive stress.

Simulation Testing Our team simulates real-world conditions using advanced equipment, such as universal testing machines and load cells, to analyze material response to compressive forces.

Data Analysis We interpret the results of simulation testing to identify potential weaknesses in materials and provide recommendations for mitigating these risks.

Recommendations and Improvements Based on our findings, we offer guidance on optimizing material selection, processing conditions, and design specifications to ensure that materials perform as expected under compressive stress.

Frequently Asked Questions (FAQs)

Q What types of materials can be tested using Eurolabs Ensuring Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues service?

A Our laboratory service is suitable for various materials, including metals, alloys, polymers, ceramics, and composites.

Q How long does the testing process take?

A The duration of our testing process varies depending on the material type and complexity of the evaluation. Typically, results are available within 1-3 weeks.

Q What information do I need to provide for a comprehensive evaluation?

A We require details about the material properties, processing conditions, and design specifications relevant to the application or product in question.

Q Can Eurolabs Ensuring Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues service help with regulatory compliance?

A Yes, our laboratory service ensures that materials meet industry-specific regulations and standards related to material properties and performance.

Conclusion

Ensuring that compressive stress does not cause cracking, warping, or other structural issues is a critical aspect of materials science and engineering. At Eurolab, we offer a comprehensive laboratory service designed to help businesses mitigate these risks and maintain material integrity. By prioritizing material quality and performance, companies can reduce costs, improve efficiency, and enhance product quality.

Contact us today to learn more about our Ensuring Compressive Stress Doesnt Cause Cracking, Warping, or Other Structural Issues service and discover how we can help your business thrive in the face of compressive stress.