Ensuring that toys designed for children are resistant to material degradation from environmental stressors

The Importance of Ensuring Toys Designed for Children are Resistant to Material Degradation from Environmental Stressors

As a business owner in the toy industry, you understand the importance of creating products that are both safe and durable for children. However, ensuring that toys designed for children are resistant to material degradation from environmental stressors is a critical aspect of product development that often gets overlooked.

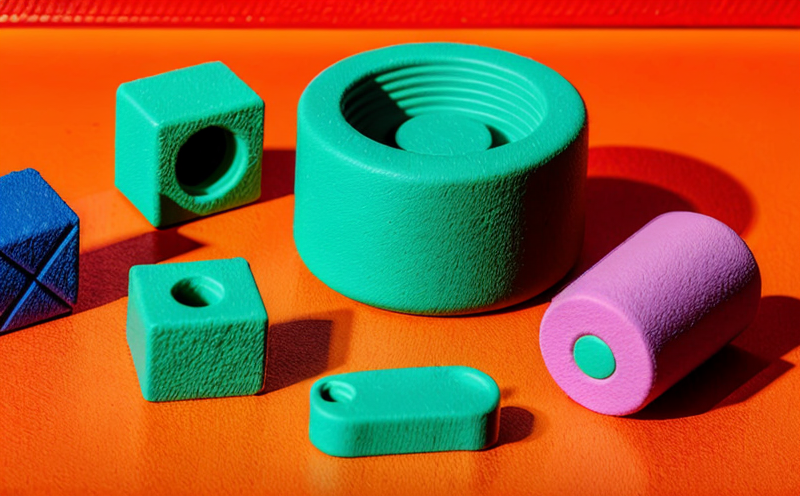

Environmental stressors such as temperature fluctuations, humidity, light exposure, and chemicals can cause materials used in toy production to degrade over time, leading to a range of issues including changes in color, texture, and even the release of harmful substances. This not only affects the aesthetic appeal and functionality of the toy but also poses risks to childrens health and safety.

At Eurolab, we specialize in providing laboratory services that help businesses like yours ensure their toys are resistant to material degradation from environmental stressors. In this article, well explore the importance of this service, the benefits it provides, and how our expert team can support your product development process.

Why is Ensuring Toys Designed for Children are Resistant to Material Degradation from Environmental Stressors Essential?

The toy industry is a multibillion-dollar market, with millions of children worldwide using toys every day. As such, manufacturers have a responsibility to ensure that their products meet the highest standards of safety and quality.

Material degradation caused by environmental stressors can lead to a range of issues including

Changes in color or texture that may affect the toys appearance and functionality

Release of harmful substances that can pose risks to childrens health

Reduced durability and lifespan of the toy, leading to unnecessary replacements and waste

Furthermore, non-compliance with regulatory requirements can result in costly recalls, damage to brand reputation, and loss of customer trust.

Advantages of Using Ensuring Toys Designed for Children are Resistant to Material Degradation from Environmental Stressors

Our laboratory services at Eurolab offer a range of benefits that can help your business ensure its toys meet the highest standards of safety and quality. Here are just some of the advantages of using our services

Improved Product Safety Our expert team will conduct comprehensive tests to identify potential material degradation issues caused by environmental stressors, ensuring your toys are safe for children to use.

Enhanced Product Durability By understanding how materials respond to environmental stressors, you can develop products that last longer and perform better, reducing unnecessary replacements and waste.

Compliance with Regulatory Requirements Our services will help you meet regulatory requirements, including those set by the Consumer Product Safety Commission (CPSC) and the European Unions General Product Safety Directive (GPSD).

Reduced Costs By identifying potential material degradation issues early on, you can avoid costly recalls, reduce waste, and minimize losses due to product failures.

Increased Customer Trust When your toys are made with safe, durable materials that resist environmental stressors, customers will trust your brand more, leading to increased loyalty and repeat business.

Key Benefits of Ensuring Toys Designed for Children are Resistant to Material Degradation from Environmental Stressors

Here are some key benefits of our laboratory services

Early Identification of Material Degradation Issues Our expert team uses advanced testing methods to identify potential material degradation issues caused by environmental stressors, enabling you to take corrective action early on.

Customized Testing Protocols We develop customized testing protocols that meet your specific needs and product requirements, ensuring accurate results and actionable insights.

Comprehensive Reporting and Analysis Our comprehensive reporting and analysis will provide you with a clear understanding of your products material degradation issues and recommendations for improvement.

QA Frequently Asked Questions About Ensuring Toys Designed for Children are Resistant to Material Degradation from Environmental Stressors

Here are some frequently asked questions about our laboratory services

Q How do I know if my toys need testing for material degradation?

A If youre unsure whether your toys meet regulatory requirements or have concerns about their safety and durability, we recommend conducting a thorough evaluation of your products using our laboratory services.

Q What types of environmental stressors are typically tested?

A Our laboratory services cover a range of environmental stressors including temperature fluctuations, humidity, light exposure, and chemicals.

Q How long does the testing process take?

A The length of time required for testing will depend on the scope of your project and the specific tests needed. Our expert team will work closely with you to develop a customized testing plan that meets your needs.

Conclusion

Ensuring that toys designed for children are resistant to material degradation from environmental stressors is a critical aspect of product development that can make all the difference in meeting regulatory requirements, ensuring product safety, and building customer trust. At Eurolab, were committed to providing expert laboratory services that help businesses like yours develop high-quality, safe products that meet the highest standards.

By choosing our laboratory services, youll gain access to a range of benefits including improved product safety, enhanced product durability, compliance with regulatory requirements, reduced costs, and increased customer trust. Dont let material degradation issues compromise your businesss reputation contact us today to learn more about how we can support your product development process.

Get Started Today

Dont wait until its too late take the first step towards ensuring your toys meet the highest standards of safety and quality. Contact Eurolab today to schedule a consultation with our expert team and discover how our laboratory services can help you overcome material degradation issues and achieve success in the toy industry.

-

Simulating the effects of environmental exposure on toys to test their long-term durability

-

Testing the resistance of toys to temperature changes, sunlight, and humidity to ensure they remain safe

-

Verifying that toys do not degrade or weaken over time when exposed to real-world environmental conditions

-

Simulating exposure to outdoor elements, such as UV rays, rain, and wind, to test toy resilience

-

Ensuring that materials used in toys do not deteriorate or lose integrity when exposed to various weather conditions

-

Testing the impact of extended storage on toys to ensure they retain their functionality and appearance

-

Verifying that toys can endure prolonged exposure to temperature extremes without becoming brittle or warped

-

Ensuring that toys do not fade, crack, or break down when exposed to repeated cycles of moisture or dryness

-

Testing toys designed for outdoor use to ensure they withstand environmental aging and continue to function

-

Simulating the passage of time to determine whether toys lose their safety or playability after long-term use

-

Ensuring that toys made from synthetic materials do not break down under the effects of UV radiation

-

Testing the resistance of toys to mold or mildew growth when exposed to high humidity or damp environments

-

Evaluating the durability of toy packaging under long-term exposure to environmental conditions

-

Ensuring that toys do not emit toxic substances or fumes after being exposed to prolonged environmental factors

-

Simulating years of wear and tear to test the effect of environmental aging on the toy’s appearance and safety

-

Testing for signs of environmental degradation in toys used for outdoor activities, such as play structures or ride-ons

-

Simulating extreme weather conditions, like snow, rain, or heat, to evaluate how toys handle adverse environments

-

Testing whether toys made of natural materials like wood or cotton resist environmental degradation

-

Ensuring that environmental aging tests do not affect the safety of toys, particularly those with small parts

-

Verifying that toys retain their usability and safety features after extended exposure to fluctuating environmental conditions

-

Simulating the impact of dust, dirt, and grime on toys to ensure they maintain their functionality and safety

-

Verifying that all materials used in toys can withstand environmental exposure without harming the child or product