Evaluating Air-Tight Seals in Airless Pump Packaging

Evaluating Air-Tight Seals in Airless Pump Packaging A Crucial Laboratory Service for Businesses

In todays fast-paced and highly competitive business landscape, ensuring the quality and integrity of packaging is more important than ever. One critical aspect of packaging evaluation that often goes unnoticed is the air-tight seal in airless pump packaging. This seemingly minor detail can have a significant impact on the performance, shelf life, and overall efficacy of your product.

At Eurolab, we understand the significance of Evaluating Air-Tight Seals in Airless Pump Packaging, and our team of expert scientists and engineers is dedicated to providing high-quality laboratory services that meet the needs of businesses like yours. In this article, we will delve into the importance of evaluating air-tight seals in airless pump packaging, highlighting the key benefits and why its essential for your business.

What is Evaluating Air-Tight Seals in Airless Pump Packaging?

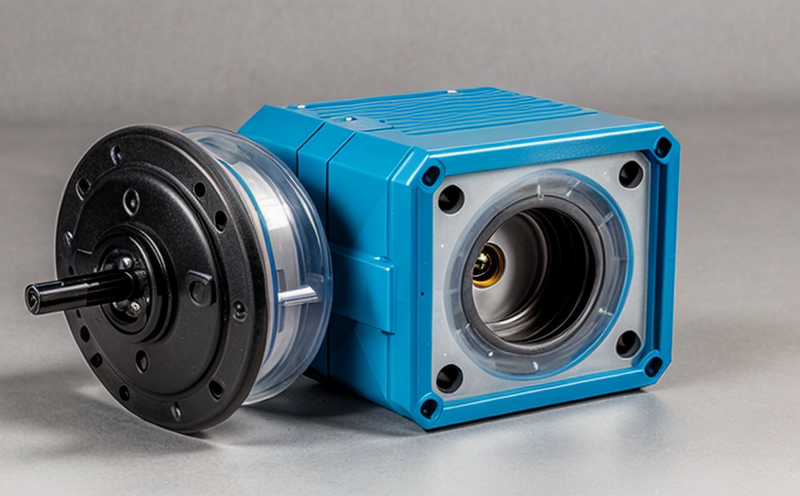

Evaluating Air-Tight Seals in Airless Pump Packaging involves testing the integrity of the seal between the product container and the pump. This is a critical evaluation because an air-tight seal ensures that the product remains in its original state, maintaining its potency and shelf life.

Airless pump packaging is widely used for various products, including cosmetics, pharmaceuticals, and personal care items. The airless pump mechanism allows for precise dosing and helps maintain product stability by minimizing exposure to air. However, if the seal between the container and the pump is compromised, it can lead to contamination, spoilage, or even product failure.

Advantages of Evaluating Air-Tight Seals in Airless Pump Packaging

The advantages of evaluating air-tight seals in airless pump packaging are numerous and can have a significant impact on your business. Here are some key benefits

Ensures Product Quality A reliable air-tight seal ensures that the product remains in its original state, maintaining its quality and potency.

Extends Shelf Life By minimizing exposure to air, you can extend the shelf life of your product, reducing waste and increasing profitability.

Reduces Contamination Risk An air-tight seal prevents contamination, which is critical for products that require sterile or aseptic packaging.

Meets Regulatory Requirements Evaluating air-tight seals helps ensure compliance with regulatory requirements, reducing the risk of product recalls and penalties.

Increases Customer Satisfaction By providing high-quality products, you can increase customer satisfaction, leading to loyalty and repeat business.

Key Benefits of Eurolabs Evaluating Air-Tight Seals in Airless Pump Packaging Service

Our laboratory service provides a range of benefits that can help your business thrive. Here are some key advantages

Accurate Results Our expert scientists and engineers use state-of-the-art equipment to provide accurate results, ensuring you have the information you need to make informed decisions.

Quick Turnaround Times We understand the importance of timely results, and our fast turnaround times ensure that you can quickly respond to any issues or concerns.

Comprehensive Reporting Our detailed reports provide a clear understanding of your products performance, including recommendations for improvement.

Frequently Asked Questions (FAQs)

Q What is the purpose of evaluating air-tight seals in airless pump packaging?

A The primary goal of this evaluation is to ensure that the seal between the container and the pump remains air-tight, preventing contamination and spoilage.

Q Why is it essential for my business?

A Evaluating air-tight seals helps ensure product quality, extends shelf life, reduces contamination risk, meets regulatory requirements, and increases customer satisfaction.

Q How do I know if I need this service?

A If you use airless pump packaging, its likely that your products require this evaluation. Contact us to discuss your specific needs and requirements.

Q What type of equipment do you use for this service?

A Our laboratory uses state-of-the-art equipment to ensure accurate results.

Conclusion

Evaluating Air-Tight Seals in Airless Pump Packaging is a crucial laboratory service that can have a significant impact on your business. By ensuring the integrity of the seal between the container and the pump, you can maintain product quality, extend shelf life, reduce contamination risk, meet regulatory requirements, and increase customer satisfaction.

At Eurolab, we are committed to providing high-quality laboratory services that meet the needs of businesses like yours. Contact us today to learn more about our Evaluating Air-Tight Seals in Airless Pump Packaging service and how it can benefit your business.