Evaluating materials used for interior and exterior finishes for their resistance to wear and tear

Evaluating Materials for Interior and Exterior Finishes Ensuring Durability and Sustainability

As businesses continue to prioritize sustainability and durability in their operations, evaluating materials used for interior and exterior finishes has become an essential service for industries worldwide. At Eurolab, our laboratory services are designed to help manufacturers, architects, and designers make informed decisions about the materials they use, ensuring that their products withstand the test of time.

What is Evaluating Materials Used for Interior and Exterior Finishes?

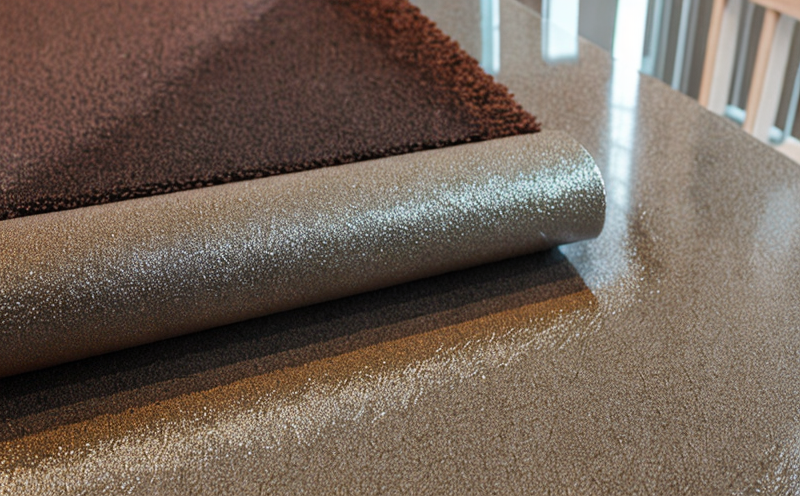

Evaluating materials used for interior and exterior finishes involves assessing a materials resistance to wear and tear, as well as its overall performance in various environmental conditions. This laboratory service helps determine whether a material can withstand exposure to sunlight, moisture, extreme temperatures, and other factors that can cause degradation.

Why is Evaluating Materials Used for Interior and Exterior Finishes Essential?

In todays competitive market, businesses must ensure that their products meet the highest standards of quality and durability. Failing to evaluate materials properly can lead to costly repairs, replacements, and even recalls. By partnering with Eurolab, manufacturers can

Minimize Product Failures Ensure that your products are designed to last, reducing the likelihood of premature failures and associated costs.

Enhance Brand Reputation Demonstrate a commitment to quality and sustainability by selecting materials that withstand the test of time.

Reduce Costs Avoid costly repairs and replacements by identifying potential issues early on.

Meet Regulatory Requirements Comply with industry standards and regulations, reducing the risk of non-compliance.

Advantages of Using Eurolabs Evaluating Materials Service

Our laboratory services offer numerous benefits for businesses looking to improve their product quality and sustainability

Comprehensive Testing Our experienced team conducts a range of tests, including

Abrasion resistance

Chemical resistance

Impact resistance

Water absorption

UV stability

Colorfastness

Customized Solutions We work closely with clients to develop tailored testing programs that meet their specific needs.

Accelerated Testing Our accelerated testing methods allow for faster results, enabling you to make informed decisions quickly.

Expert Interpretation Our team provides detailed reports and expert interpretation of test results, helping you understand the implications for your products.

Key Benefits of Evaluating Materials Used for Interior and Exterior Finishes

By partnering with Eurolab, businesses can

Improve Product Lifespan Ensure that materials are designed to last, reducing maintenance and repair costs.

Enhance Customer Satisfaction Deliver high-quality products that meet customer expectations and preferences.

Reduce Environmental Impact Select sustainable materials that minimize waste and reduce environmental harm.

Stay Ahead of Competition Differentiate your business by prioritizing quality and sustainability.

Frequently Asked Questions

Q What types of materials can be tested using Eurolabs evaluating materials service?

A Our laboratory services can test a wide range of materials, including paints, coatings, laminates, textiles, plastics, and more.

Q How do I know which tests to conduct on my material?

A Our experienced team will work with you to determine the most relevant tests for your specific needs.

Q Can Eurolab provide customized testing programs for our business?

A Yes, we offer tailored testing solutions that meet the unique requirements of each client.

Q How long does it take to receive test results from Eurolab?

A Our accelerated testing methods allow for faster results, with most tests completed within a few days or weeks.

Conclusion

Evaluating materials used for interior and exterior finishes is a critical service that helps businesses ensure their products meet the highest standards of quality and sustainability. By partnering with Eurolab, manufacturers can minimize product failures, enhance brand reputation, reduce costs, and meet regulatory requirements. Our comprehensive testing services, customized solutions, and expert interpretation provide unparalleled support for industries worldwide.

Dont compromise on quality or sustainability choose Eurolabs evaluating materials service to ensure your products stand the test of time.

-

Testing the ability of materials to resist surface wear due to friction or rubbing

-

Simulating conditions where construction materials experience frequent contact with rough surfaces

-

Evaluating how well materials hold up under abrasive forces that can cause surface damage or degradation

-

Testing the durability of materials used in flooring, pavements, and high-traffic areas against abrasion

-

Ensuring that materials retain their appearance and function despite exposure to wear and tear

-

Verifying that construction materials, such as coatings and paints, remain intact after prolonged use

-

Simulating the effects of mechanical wear on materials such as metals, concrete, and plastics

-

Testing the effectiveness of protective coatings against abrasion, particularly in outdoor environments

-

Evaluating the resistance of materials used in the construction of roads, sidewalks, and parking areas

-

Testing for scratches, gouges, or erosion on materials exposed to abrasive particles or tools

-

Ensuring that construction materials used in industrial environments maintain their strength and integrity under abrasion

-

Testing how well materials resist damage from contact with other materials, such as machinery or tools

-

Ensuring that materials used for roofing, siding, and cladding can withstand frequent exposure to dust and dirt

-

Verifying that materials used in construction equipment can resist damage from abrasive substances like sand or grit

-

Simulating high-wear conditions in construction to assess the long-term performance of materials

-

Ensuring that materials used for flooring in commercial spaces can resist the effects of foot traffic and machinery

-

Testing the ability of materials to resist pitting or surface degradation under constant friction

-

Testing for the ability of materials to maintain structural integrity and appearance after heavy mechanical handling

-

Ensuring that materials used in industrial construction can withstand abrasive cleaning processes

-

Verifying the durability of construction materials used in mining, oil, or heavy machinery environments

-

Evaluating how abrasion resistance affects the longevity and maintenance needs of construction materials