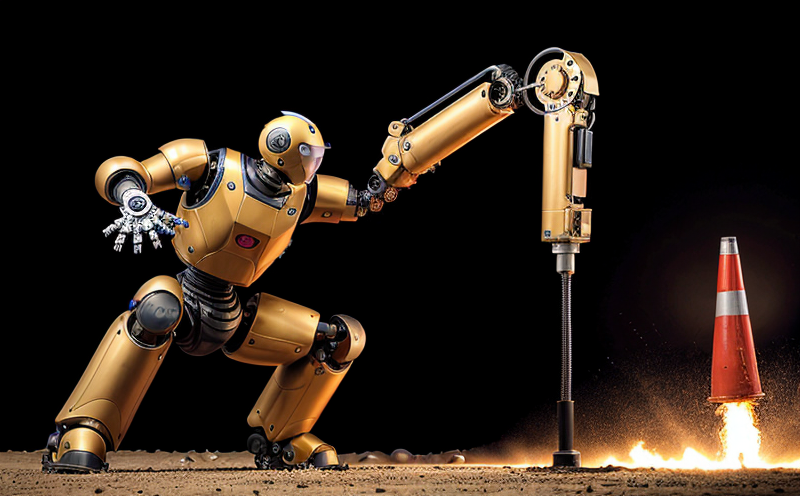

Evaluating the ability of robotic arms to cease movement instantly when a safety stop is initiated

Evaluating Robotic Arms Instant Safety Stop - A Game-Changer for Industry Efficiency

In todays fast-paced industrial landscape, the integration of robotic arms has become an essential component of manufacturing and production processes. These intelligent machines have revolutionized industries by increasing efficiency, accuracy, and productivity. However, with great power comes great responsibility, and ensuring the safety of both humans and equipment is paramount. This is where Evaluating the ability of robotic arms to cease movement instantly when a safety stop is initiated comes into play - a crucial laboratory service provided by Eurolab.

In this article, we will delve into the world of robotic arm safety evaluation, exploring its significance, benefits, and key takeaways. Whether youre an industry expert or just starting your journey with robotic arms, this comprehensive guide will equip you with the knowledge necessary to make informed decisions about ensuring the safe operation of these vital machines.

What is Evaluating the ability of robotic arms to cease movement instantly when a safety stop is initiated?

At its core, evaluating the instant cessation of robotic arm movement upon initiating a safety stop involves analyzing and testing the effectiveness of a machines safety protocols. This intricate process ensures that robotic arms can halt their operations quickly and safely in case of an emergency or unexpected event. The primary goal of this evaluation is to guarantee the safeguarding of human life, equipment, and operational continuity.

Advantages of Evaluating the ability of robotic arms to cease movement instantly when a safety stop is initiated

The benefits of evaluating robotic arm safety are multifaceted and far-reaching

Reduced Risk of Accidents By verifying that your robotic arms can come to an immediate halt in case of an emergency, you minimize the risk of accidents, injuries, and even fatalities.

Enhanced Equipment Safety Regular evaluations ensure that your robotic arms mechanical and electrical components are functioning within safety parameters, reducing the likelihood of equipment failure or damage.

Increased Productivity With a reliable and efficient safety system in place, you can optimize production processes, reduce downtime, and improve overall plant performance.

Compliance with Industry Regulations Compliance with regulatory requirements is crucial. Evaluating your robotic arms safety capabilities ensures adherence to relevant standards and codes, protecting your business from potential liabilities.

Improved Maintenance Scheduling Accurate assessments of your robotic arms operational status enable informed maintenance planning, reducing unnecessary repairs and minimizing equipment downtime.

Cost Savings By identifying and addressing potential issues early on, you avoid costly repairs, replacements, or even complete system overhauls.

Why Choose Eurolab for Evaluating the ability of robotic arms to cease movement instantly when a safety stop is initiated?

At Eurolab, we pride ourselves on providing expert laboratory services tailored to your specific needs. Our team of experienced professionals combines technical knowledge with cutting-edge equipment to deliver comprehensive and accurate assessments. By partnering with Eurolab, you can

Benefit from Expertise Leverage our extensive experience in robotic arm safety evaluation, ensuring that your machines are thoroughly tested and evaluated.

Gain Confidence Trust our certified laboratory services for unbiased and reliable results, providing you with the assurance needed to optimize your operations.

Enhance Safety Culture By prioritizing safety through regular assessments, you foster a culture of responsibility within your organization, promoting a safer working environment for all employees.

QA Evaluating the ability of robotic arms to cease movement instantly when a safety stop is initiated

Q What are the most common reasons for robotic arm malfunctions?

A Common causes include software glitches, mechanical failures, and inadequate maintenance. Regular evaluations can help identify and address these issues before they lead to downtime or accidents.

Q How often should I evaluate my robotic arms safety capabilities?

A As a general guideline, we recommend quarterly assessments for high-traffic areas or critical production processes. More frequent evaluations may be necessary depending on your specific operational requirements.

Q What happens if my robotic arm fails to stop instantly during an evaluation?

A In the event of a failed test, our team will work closely with you to identify the root cause and implement corrective measures to rectify the issue. This ensures that your machines are functioning safely and efficiently.

Conclusion

Evaluating the ability of robotic arms to cease movement instantly when a safety stop is initiated is an indispensable aspect of maintaining a safe and efficient industrial operation. By partnering with Eurolab, you can ensure that your robotic arms meet the highest standards of safety and performance. Dont compromise on your businesss well-being choose the experts at Eurolab for comprehensive laboratory services tailored to your specific needs.

Get in touch

At Eurolab, were committed to supporting your industrys growth through cutting-edge services. For more information about evaluating robotic arm safety or to schedule an assessment, please visit our website or contact us directly.