Evaluating the adhesion of labels to packaging materials

Evaluating the Adhesion of Labels to Packaging Materials Ensuring Label Integrity for Your Business

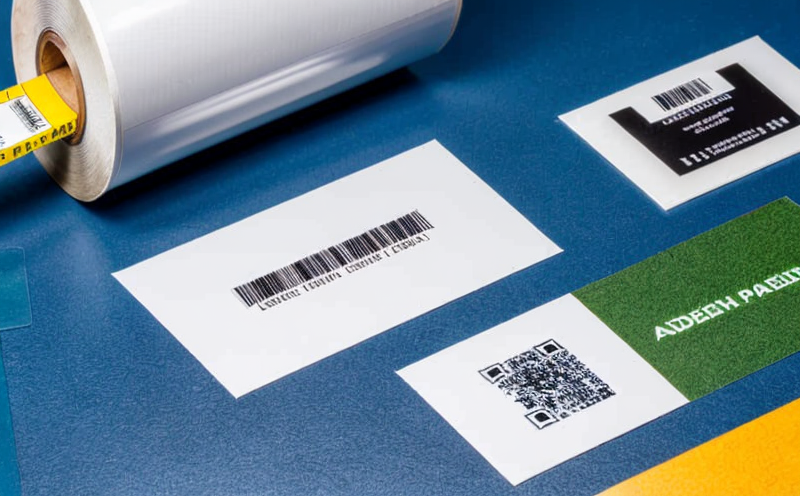

In todays fast-paced and competitive market, businesses are constantly seeking ways to differentiate themselves from their rivals while maintaining product quality and consistency. One often-overlooked aspect of packaging is label adhesion - the strength with which labels bond to packaging materials. Evaluating the adhesion of labels to packaging materials is a crucial laboratory service that ensures your products labels adhere reliably, even in harsh environments or during shipping and handling.

At Eurolab, our team of experts provides comprehensive lab testing services to help businesses like yours evaluate the adhesion strength of their product labels. This critical evaluation helps prevent label failures, damage, or detachment from packaging materials - a costly issue for companies looking to maintain brand reputation, customer trust, and product quality.

Why is Evaluating Adhesion Important?

Label adhesion plays a significant role in maintaining the integrity and appearance of your products. If your labels do not adhere properly, they may

Detach prematurely, affecting product visibility and shelf appeal

Leak or release contents during transportation or storage, compromising product safety

Experience uneven wear and tear, leading to inconsistent labeling

Failing to evaluate label adhesion can result in significant losses for your business. Label-related issues can lead to costly recalls, brand damage, customer dissatisfaction, and ultimately, financial losses.

Advantages of Using Eurolabs Adhesion Evaluation Services

Our laboratory is committed to providing accurate, reliable results that help you optimize your labeling strategy. Some key benefits of using our adhesion evaluation services include

Enhanced Label Reliability Ensure your labels remain securely attached even in challenging environments.

Improved Customer Satisfaction Avoid costly label-related issues and maintain customer trust with consistent labeling.

Reduced Brand Damage Protect your brand reputation by ensuring labels adhere reliably, reducing the likelihood of product defects or damage.

Increased Efficiency Save time and resources by identifying and addressing label adhesion issues early on.

Benefits in Detail

Enhanced Label Reliability

Our expert technicians conduct rigorous testing to assess label adhesion under various conditions, including

Static and dynamic forces We simulate real-world situations where labels are exposed to constant stress or rapid acceleration.

Temperature extremes Our controlled environments test labels at high and low temperatures to ensure they maintain their adhesive properties.

Moisture exposure Labels are subjected to simulated humidity and moisture conditions to evaluate their durability.

Improved Customer Satisfaction

Properly adhering labels contribute significantly to customer satisfaction, which in turn affects your businesss bottom line. Our services help you

Minimize label failures By identifying potential adhesion issues early on, we enable you to address them proactively.

Maintain a consistent product image Ensure your products appearance remains professional and appealing throughout the supply chain.

Reduced Brand Damage

Inadequate labeling can lead to costly recalls, damaged brand reputation, and reduced customer loyalty. Our services help

Prevent label-related issues Identify potential adhesion problems before they become major concerns.

Protect your brands image Maintain consistent labeling across all products and packaging materials.

Increased Efficiency

By evaluating the adhesion of labels to packaging materials, you can

Reduce product recalls Avoid costly and time-consuming product recalls due to label-related issues.

Save resources Focus on core business activities while our experts handle lab testing and analysis.

Frequently Asked Questions (FAQs)

What types of products benefit from adhesion evaluation?

Our services cater to a wide range of industries, including food and beverage, pharmaceuticals, cosmetics, and consumer goods.

How do I prepare samples for testing?

Please provide us with your original packaging materials and labels. We will handle the sample preparation process according to industry standards.

What types of testing methods are used at Eurolab?

Our experienced technicians employ various testing techniques, including tensile strength tests, peel adhesion tests, and lap shear tests, among others.

How long does it take to receive test results?

We strive to provide rapid turnaround times while maintaining the highest level of accuracy. Results typically become available within 24-48 hours, depending on the complexity of the testing process.

Can I request customized testing protocols?

Yes! Our team works closely with clients to develop tailored testing plans that meet their specific needs and requirements.

Conclusion

Evaluating the adhesion of labels to packaging materials is a critical step in ensuring label integrity for your business. At Eurolab, our dedicated team offers expert laboratory services to help you optimize labeling strategies, reduce costs, and enhance customer satisfaction. Dont let label-related issues compromise your products appearance or performance - trust our experts to provide reliable results that support your business growth.

Get Started Today

Take the first step towards a more efficient, cost-effective, and customer-centric labeling strategy. Contact us at insert contact information, if required to discuss how Eurolab can help you evaluate the adhesion of labels to packaging materials.