Evaluating the behavior of aerospace materials under simulated wind forces

Evaluating the Behavior of Aerospace Materials Under Simulated Wind Forces Unlocking Safety and Efficiency in Aviation

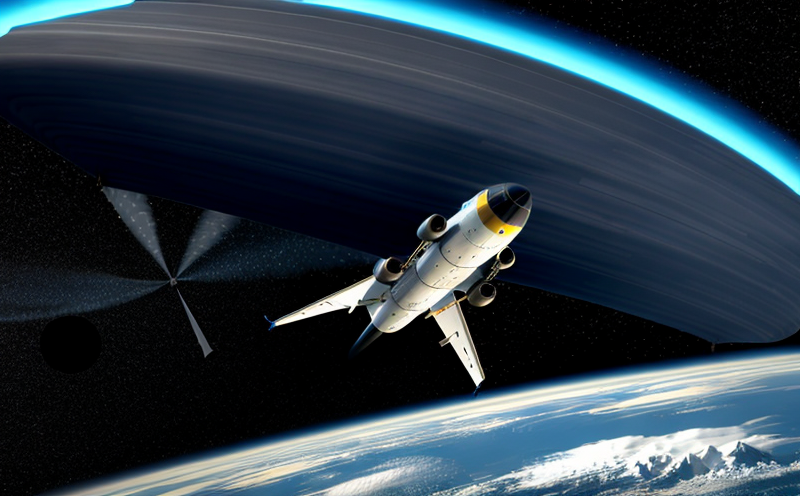

As the aviation industry continues to evolve at a breakneck pace, manufacturers and engineers are under increasing pressure to develop materials that can withstand the unforgiving conditions of flight. One critical factor that determines the safety and performance of aircraft is their ability to resist wind forces, which can cause damage, loss of control, and even catastrophic failure. To mitigate these risks, aerospace companies require a thorough understanding of how their materials behave under simulated wind forces.

At Eurolab, our laboratory service provides an essential solution for businesses looking to optimize the performance and safety of their aircraft. By evaluating the behavior of aerospace materials under simulated wind forces, we enable manufacturers to identify areas of improvement, reduce costs, and ensure compliance with regulatory standards. In this article, we will delve into the importance of this testing service, its advantages, and how it can benefit your business.

The Importance of Evaluating Aerospace Materials Under Simulated Wind Forces

Aircraft are exposed to a wide range of wind forces during flight, including turbulence, gusts, and crosswinds. These forces can cause stress on the airframe, wings, and control surfaces, leading to damage or failure. The consequences of such events can be severe, resulting in lost revenue, damaged reputation, and even loss of life.

To mitigate these risks, aerospace companies must develop materials that are capable of withstanding wind forces without compromising safety. This requires a deep understanding of the materials properties, including its strength, stiffness, and durability. Evaluating the behavior of aerospace materials under simulated wind forces provides this critical information, enabling manufacturers to

Optimize material selection By testing materials under simulated wind forces, companies can identify those that perform best in specific conditions.

Improve design integrity Testing helps engineers understand how materials will behave in service, allowing them to optimize designs for maximum safety and efficiency.

Reduce costs Identifying areas of improvement early on saves resources and reduces the likelihood of costly rework or redesign.

Advantages of Using Eurolabs Laboratory Service

Our laboratory service offers a range of benefits that can transform your business. Here are just a few

Comprehensive testing capabilities Our state-of-the-art facilities enable us to simulate wind forces on a wide range of materials, from traditional metals and composites to advanced materials like 3D-printed components.

Expert analysis and reporting Our experienced team provides detailed reports that outline the materials performance under simulated wind forces, including recommendations for improvement.

Regulatory compliance Our testing services ensure that your products meet or exceed relevant standards and regulations, reducing the risk of non-compliance.

Reduced development time By identifying areas of improvement early on, you can accelerate your product development cycle and get to market faster.

Key Benefits for Your Business

Here are just a few ways our laboratory service can benefit your business

Improved safety Our testing helps ensure that your aircraft materials meet the highest standards of safety, reducing the risk of accidents or damage.

Increased efficiency By optimizing material selection and design integrity, you can reduce costs and improve performance.

Competitive advantage Companies that invest in evaluating their aerospace materials under simulated wind forces gain a competitive edge in terms of innovation, quality, and reputation.

Enhanced customer trust By demonstrating your commitment to safety and quality, you build trust with customers and stakeholders, driving revenue growth and brand loyalty.

QA Evaluating the Behavior of Aerospace Materials Under Simulated Wind Forces

Here are some frequently asked questions about our laboratory service

Q What types of materials can be tested?

A Our facilities can simulate wind forces on a wide range of materials, including metals, composites, ceramics, and advanced materials like 3D-printed components.

Q How do you ensure the accuracy of your testing results?

A We utilize state-of-the-art equipment and follow industry-standard protocols to ensure that our testing results are accurate and reliable.

Q What kind of reports can I expect from Eurolabs laboratory service?

A Our experienced team provides comprehensive reports that outline the materials performance under simulated wind forces, including recommendations for improvement.

Q Can you accommodate large or complex projects?

A Yes. We have extensive experience working with large and complex projects and are equipped to handle even the most demanding requirements.

Conclusion

Evaluating the behavior of aerospace materials under simulated wind forces is a critical step in ensuring the safety and performance of aircraft. By partnering with Eurolab, you can unlock the full potential of your materials and designs, reducing costs and improving efficiency. Dont compromise on quality choose the best solution for your business. Contact us today to learn more about our laboratory service and how it can benefit your organization.

---

About Eurolab

At Eurolab, we pride ourselves on providing industry-leading laboratory services that meet the highest standards of quality and accuracy. Our team of experts is dedicated to helping aerospace companies like yours optimize their materials and designs for maximum safety and efficiency. Contact us today to learn more about our laboratory service and how it can transform your business.