Evaluating the design of battery enclosures to ensure protection against external impact

Evaluating the Design of Battery Enclosures A Crucial Service for Businesses to Ensure Safety and Compliance

In todays fast-paced world, batteries are an essential component in various industries, including automotive, aerospace, renewable energy, and consumer electronics. However, with great power comes great responsibility the risk of external impact on battery enclosures can have devastating consequences, compromising safety, efficiency, and compliance with regulatory standards.

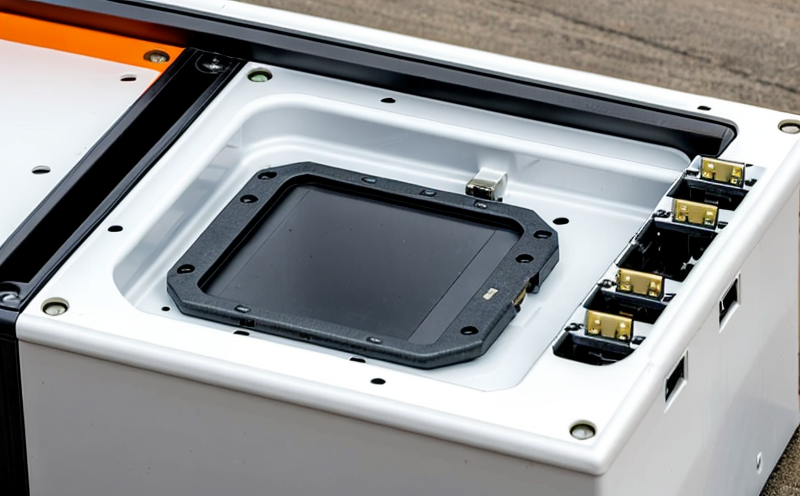

Battery enclosures are designed to safeguard batteries from environmental stressors, such as vibrations, shocks, and extreme temperatures. Nevertheless, even the most robust designs can fail when subjected to unexpected forces or impacts. This is where Eurolabs laboratory service comes into play Evaluating the design of battery enclosures to ensure protection against external impact. By leveraging our expertise and state-of-the-art facilities, businesses can ensure their battery enclosures meet the stringent requirements for reliability, safety, and performance.

In this article, well delve into the significance of evaluating battery enclosure designs, highlighting the advantages of using Eurolabs laboratory service. Well also provide an in-depth breakdown of the benefits, key takeaways, and frequently asked questions to help you make informed decisions about your businesss needs.

Why Evaluating Battery Enclosure Designs is Essential

Battery enclosures are subject to various hazards, including

External impacts Drops, bumps, or crushing forces can compromise the structural integrity of the enclosure.

Temperature fluctuations Extreme temperatures can affect battery performance, reliability, and lifespan.

Vibrations Repeated exposure to vibrations can cause mechanical fatigue, leading to premature failure.

Failure to evaluate battery enclosure designs can result in catastrophic consequences, including

Device malfunction Damaged batteries can lead to system failures, causing downtime, lost productivity, and financial losses.

Safety risks Battery-related incidents can pose serious threats to human life, health, and property.

Compliance issues Non-compliance with regulatory standards can result in costly fines, recalls, or reputational damage.

Benefits of Using Eurolabs Laboratory Service

By leveraging our laboratory service, youll gain access to

Expert analysis Our team of experienced engineers and technicians will conduct thorough evaluations of your battery enclosure designs.

State-of-the-art facilities We utilize cutting-edge equipment and testing methodologies to simulate real-world scenarios.

Comprehensive reports Receive detailed, actionable insights into the performance and reliability of your battery enclosures.

Key Benefits of Evaluating Battery Enclosure Designs

Here are some key benefits of using Eurolabs laboratory service

Advantages for Businesses

Reduced risk of device malfunction

Improved safety and compliance with regulatory standards

Increased product reliability and lifespan

Enhanced customer satisfaction and loyalty

Competitive advantage through differentiation and innovation

Benefits for Regulatory Compliance

Compliance with industry-specific regulations (e.g., IEC, UL, ISO)

Conformity to safety standards (e.g., CE marking, UL certification)

Advantages for Innovation and Development

Data-driven decision-making for design optimization

Access to cutting-edge testing methodologies and equipment

Expert guidance on regulatory requirements and industry trends

Frequently Asked Questions (FAQs)

Here are some commonly asked questions about Eurolabs laboratory service

Q What types of battery enclosures can be evaluated?

A We evaluate a wide range of battery enclosure designs, including those for automotive, aerospace, renewable energy, and consumer electronics applications.

Q How do you conduct evaluations?

A Our team uses state-of-the-art equipment and testing methodologies to simulate real-world scenarios. This may include mechanical testing (e.g., drop tests), thermal testing (e.g., temperature cycling), and vibration testing.

Q What kind of reports can I expect from the evaluation process?

A Youll receive detailed, actionable insights into the performance and reliability of your battery enclosures, including recommendations for design optimization and improvement.

Q Can I get in touch with Eurolab to learn more about their services?

A Yes! Our team is committed to providing exceptional service and support. We encourage you to reach out to us through our website or other official channels for more information.

Conclusion

Evaluating the design of battery enclosures to ensure protection against external impact is a critical aspect of product development, particularly in industries where safety, reliability, and regulatory compliance are paramount. By partnering with Eurolabs laboratory service, businesses can tap into expert analysis, state-of-the-art facilities, and comprehensive reports to optimize their designs.

Dont compromise on the integrity and performance of your battery enclosures choose Eurolabs trusted laboratory service for peace of mind, improved efficiency, and enhanced customer satisfaction.