Evaluating the effectiveness of aerospace lubricants in reducing friction and wear

Evaluating the Effectiveness of Aerospace Lubricants in Reducing Friction and Wear Unlocking Efficiency and Safety in Aviation

As the aerospace industry continues to push the boundaries of innovation and efficiency, lubrication plays a critical role in ensuring the optimal performance and longevity of aircraft components. However, with an array of lubricant options available, selecting the most effective one can be a daunting task for manufacturers, operators, and maintenance teams. This is where Eurolabs laboratory service Evaluating the Effectiveness of Aerospace Lubricants in Reducing Friction and Wear comes into play.

In this article, we will delve into the importance of evaluating aerospace lubricants, highlighting their advantages and benefits. We will also provide a comprehensive QA section to address common queries related to our laboratory service.

Why Evaluating the Effectiveness of Aerospace Lubricants is Essential

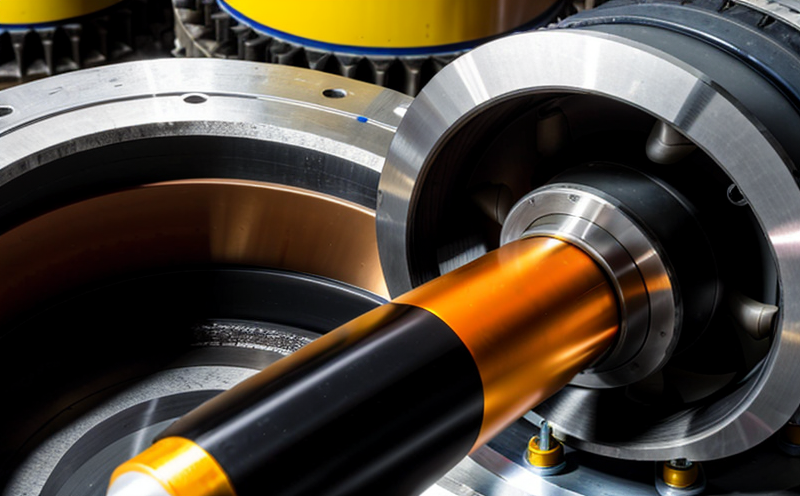

The performance of aircraft depends on a delicate balance between various components, including engines, gears, bearings, and other moving parts. Lubrication plays a crucial role in reducing friction and wear on these components, thereby ensuring efficient operation and extending their lifespan.

However, traditional methods of lubricant selection often rely on trial-and-error approaches or generic guidelines, which may not account for the unique operating conditions and requirements of specific aircraft systems. This can lead to suboptimal lubricant performance, compromising safety, efficiency, and overall operational costs.

Eurolabs Evaluating the Effectiveness of Aerospace Lubricants in Reducing Friction and Wear laboratory service bridges this knowledge gap by providing an objective assessment of lubricant performance under realistic operating conditions. Our expert team conducts a thorough analysis of lubricant properties, including viscosity, shear stability, oxidation resistance, and wear protection, to determine their suitability for various aerospace applications.

Advantages of Using Eurolabs Laboratory Service

The advantages of using Eurolabs laboratory service are numerous

Improved Lubricant Performance Our expert team analyzes lubricant performance under realistic operating conditions, ensuring optimal results.

Reduced Maintenance Costs By selecting the most effective lubricant for your application, you can reduce maintenance costs associated with premature wear and tear.

Enhanced Safety Our laboratory service helps ensure that aircraft components are properly protected against corrosion and wear, reducing the risk of catastrophic failures.

Increased Efficiency With optimized lubricant performance, you can improve engine efficiency, reduce fuel consumption, and increase overall operational performance.

Key Benefits

Customized Lubricant Solutions Eurolabs laboratory service provides tailored recommendations for specific aerospace applications, ensuring optimal results.

Comprehensive Testing Our expert team conducts a thorough analysis of lubricant properties, including viscosity, shear stability, oxidation resistance, and wear protection.

Objective Assessment Our laboratory service provides an unbiased evaluation of lubricant performance, free from manufacturer influence.

Data-Driven Decision Making Our expert team provides actionable insights based on data-driven results, ensuring informed decision-making.

QA Section

Q What is the purpose of Eurolabs Evaluating the Effectiveness of Aerospace Lubricants laboratory service?

A The primary objective of our laboratory service is to evaluate the performance of aerospace lubricants in reducing friction and wear under realistic operating conditions. We provide an objective assessment of lubricant properties, ensuring optimal results.

Q How does Eurolabs laboratory service differ from traditional methods of lubricant selection?

A Unlike generic guidelines or trial-and-error approaches, our laboratory service relies on a comprehensive analysis of lubricant performance under specific operating conditions, providing tailored recommendations for aerospace applications.

Q What types of aerospace components can be evaluated using Eurolabs laboratory service?

A Our laboratory service is suitable for various aircraft systems, including engines, gears, bearings, and other moving parts. We provide customized solutions for specific aerospace applications.

Conclusion

Evaluating the Effectiveness of Aerospace Lubricants in Reducing Friction and Wear is a critical aspect of ensuring optimal performance and safety in aviation. Eurolabs laboratory service provides an objective assessment of lubricant properties, enabling informed decision-making and reducing maintenance costs.

By choosing our laboratory service, you can unlock efficiency, safety, and cost savings for your aerospace operations. Contact us today to learn more about how we can help optimize your lubricant performance.