Evaluating the performance of abrasive-resistant materials in consumer products

Evaluating the Performance of Abrasive-Resistant Materials in Consumer Products Unlocking Business Success with Eurolabs Expert Laboratory Services

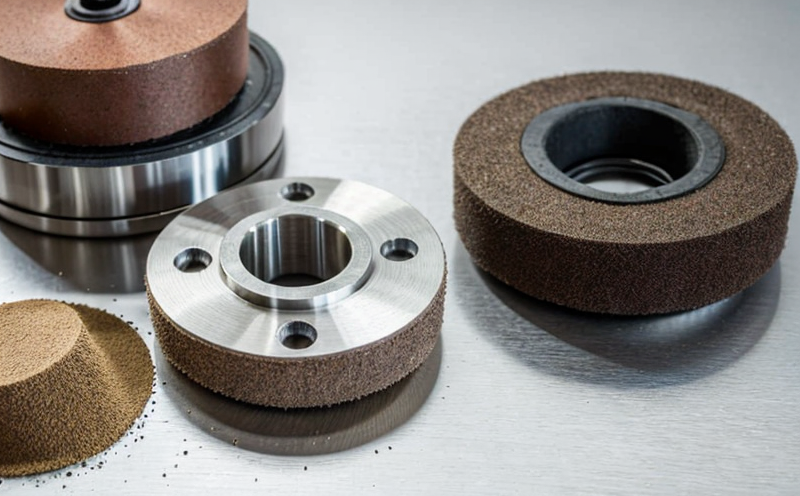

In todays fast-paced consumer goods industry, manufacturers are constantly seeking innovative ways to differentiate their products and meet the evolving demands of discerning customers. One critical aspect that often gets overlooked is the performance of abrasive-resistant materials used in various applications. Abrasion resistance is a crucial property for many products, particularly those exposed to wear and tear, such as textiles, coatings, and polymer-based materials.

However, assessing the abrasion resistance of these materials can be a complex and time-consuming process, requiring specialized expertise and equipment. This is where Eurolab comes in our laboratory provides an essential service that helps businesses evaluate the performance of abrasive-resistant materials in consumer products. By partnering with us, you can gain valuable insights into your products durability and lifespan, enabling informed decisions to enhance its overall quality and competitiveness.

Why Evaluating Abrasive-Resistant Materials is Essential for Businesses

Abrasion resistance plays a vital role in ensuring the longevity and performance of various products. Inadequate abrasion resistance can lead to reduced product life, increased maintenance costs, and compromised user satisfaction. By evaluating the abrasive-resistant properties of materials used in your products, you can

Extend Product Lifespan Identify areas where materials may be prone to wear and tear, enabling targeted improvements to enhance overall durability.

Reduce Maintenance Costs Minimize repair and replacement needs by selecting materials with optimal abrasion resistance.

Enhance User Satisfaction Ensure that products meet customer expectations for quality, reliability, and performance.

Key Benefits of Using Eurolabs Evaluating the Performance of Abrasive-Resistant Materials in Consumer Products Service

Our laboratory service offers numerous advantages for businesses seeking to optimize their product development process. Some key benefits include

Accurate Material Selection Leverage our expertise to choose the most suitable materials for your products, reducing the risk of material failure and ensuring optimal performance.

Increased Product Reliability Identify potential abrasion-related issues early on, enabling targeted improvements to enhance overall product reliability.

Cost Savings Minimize production costs by selecting materials with optimal abrasion resistance, reducing the need for costly repairs and replacements.

Compliance with Industry Standards Ensure that your products meet relevant industry standards and regulations regarding abrasion resistance.

Competitive Advantage Differentiate your business by offering high-quality products with exceptional performance, setting you apart from competitors in the market.

QA Evaluating the Performance of Abrasive-Resistant Materials in Consumer Products with Eurolab

Q1 What types of materials can be evaluated for abrasive resistance?

A1 Our laboratory services cover a wide range of materials used in consumer products, including textiles, coatings, polymers, and more.

Q2 How do you evaluate abrasive resistance in materials?

A2 We employ state-of-the-art testing equipment and methodologies to assess the abrasion resistance of materials, providing accurate and reliable results.

Q3 Can Eurolab help with product development and design recommendations based on the evaluation results?

A3 Yes, our expert team provides actionable insights and guidance to inform product development decisions, ensuring that your products meet the highest standards of quality and performance.

Q4 What are the benefits of partnering with a third-party laboratory like Eurolab for evaluating abrasive-resistant materials?

A4 By outsourcing material evaluation to us, you can tap into our specialized expertise, reducing internal costs and enabling faster product development cycles while ensuring high-quality results.

Conclusion

Evaluating the performance of abrasive-resistant materials in consumer products is a critical aspect of product development that requires specialized knowledge and equipment. By partnering with Eurolabs laboratory services, businesses can unlock valuable insights to enhance their product offerings, improve user satisfaction, and gain a competitive edge in the market. Our expert team is dedicated to providing accurate and reliable results, empowering you to make informed decisions that drive business success.

-

Testing the resistance of consumer product surfaces to wear and tear from repeated contact

-

Evaluating the durability of coatings, paints, and finishes under abrasive conditions

-

Assessing the impact of friction and surface rubbing on the aesthetic and functional properties of products

-

Simulating everyday use, such as scratching or rubbing, to test the longevity of surface finishes

-

Testing for changes in appearance or performance due to surface abrasion in items like clothing, electronics, or furniture

-

Evaluating the effectiveness of protective coatings or surface treatments in preventing abrasion damage

-

Simulating high-traffic conditions to test the resilience of consumer goods surfaces to abrasion

-

Testing the impact of cleaning or maintenance on the surface durability of products

-

Assessing the abrasion resistance of materials used in consumer goods, such as textiles, plastics, and metals

-

Simulating the effects of abrasions caused by various objects or surfaces on the product’s surface

-

Evaluating wear patterns and their potential impact on the functionality of products after prolonged use

-

Testing for scratches, scuffs, and other visible signs of damage caused by abrasion

-

Assessing the environmental factors that influence surface wear, such as moisture, temperature, and dust

-

Simulating the impact of long-term use and exposure to various abrasive materials

-

Testing the resistance of products to abrasion in real-world consumer settings, such as kitchens or vehicles

-

Verifying that products maintain their aesthetic appeal and function despite surface abrasion

-

Testing for surface degradation due to contact with various types of fabrics or rough materials

-

Simulating scenarios where products come into contact with abrasive materials during shipping or handling

-

Assessing product performance after repeated exposure to abrasive forces in typical use cases