Evaluating the performance of anti-corrosion coatings on defense materials

Evaluating the Performance of Anti-Corrosion Coatings on Defense Materials Why Accuracy Matters for Businesses

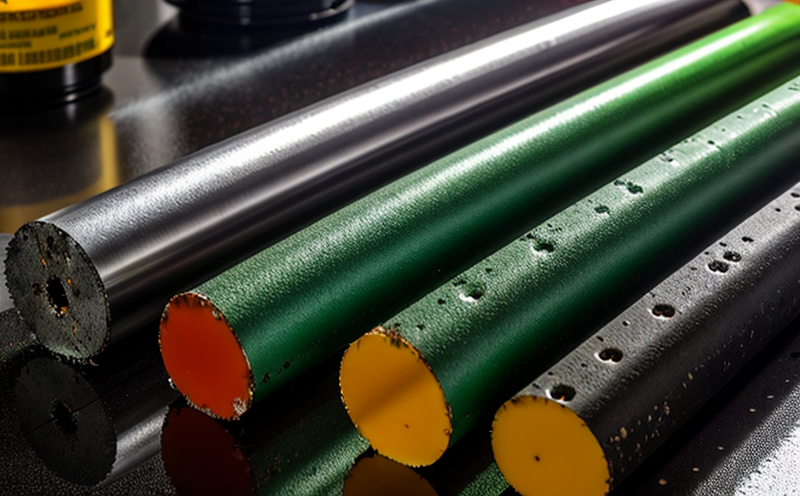

In todays fast-paced world, where defense materials play a critical role in safeguarding national security and protecting military assets, the need for high-quality anti-corrosion coatings cannot be overstated. These specialized coatings are designed to shield sensitive equipment from harsh environmental conditions, ensuring they remain operational even under extreme stress. However, the effectiveness of these coatings can only be guaranteed if their performance is rigorously evaluated. This is where Eurolab comes in a leading laboratory services provider offering expert evaluation and testing solutions for defense materials.

The Critical Importance of Evaluating Anti-Corrosion Coatings on Defense Materials

Corrosion can have devastating consequences for military assets, from reducing their lifespan to compromising their functionality. In the worst-case scenario, corroded equipment can become non-functional, leading to costly delays in critical missions and jeopardizing the safety of personnel involved. Therefore, it is essential that defense manufacturers and users choose coatings with confidence, knowing they will perform consistently under various environmental conditions.

Key Benefits of Evaluating Anti-Corrosion Coatings on Defense Materials

Here are some compelling reasons why businesses should invest in evaluating anti-corrosion coatings

Improved Reliability By testing anti-corrosion coatings, you can be certain that your equipment will withstand the harshest conditions. This reduces the risk of unexpected equipment failures and ensures a higher level of operational readiness.

Enhanced Safety Corrosion-related issues can lead to accidents and injuries on military bases. Evaluating anti-corrosion coatings helps prevent these incidents, ensuring personnel safety while working with sensitive equipment.

Extended Equipment Lifespan Properly evaluated coatings enable defense materials to perform optimally over a longer period, reducing the need for premature replacements and saving resources.

Compliance with Regulations Governments worldwide have stringent regulations governing the use of anti-corrosion coatings in defense industries. Eurolabs expert evaluation services ensure your equipment meets all necessary standards and complies with local and international laws.

Reduced Maintenance Costs Corrosion can significantly increase maintenance costs due to damage repairs, lost productivity, and other associated expenses. Testing anti-corrosion coatings minimizes these costs by ensuring your equipment remains in top condition for extended periods.

Optimized Performance Evaluation of anti-corrosion coatings enables you to identify the best possible coating solutions for specific environmental conditions, guaranteeing optimal performance and reliability.

QA Frequently Asked Questions about Evaluating Anti-Corrosion Coatings on Defense Materials

Q What types of testing do Eurolabs experts offer?

A Our comprehensive services include salt spray testing, humidity chamber testing, and other specialized evaluations tailored to meet specific defense industry requirements.

Q How do I know which anti-corrosion coating is best suited for my equipment?

A Our expert analysts will work with you to determine the most suitable coating based on your unique needs, taking into account factors such as environmental conditions, exposure duration, and expected lifespan.

Q Can Eurolab provide customized testing solutions?

A Yes. We recognize that every project is distinct, so we offer bespoke testing packages designed to meet specific client needs.

Q What kind of documentation can I expect from Eurolabs evaluation services?

A After completing the testing process, you will receive a detailed report outlining our findings and recommendations for improvement or optimization.

Q Are your experts certified to work with defense materials?

A Absolutely. Our team includes experienced professionals with extensive knowledge in anti-corrosion coatings and specialized testing procedures relevant to the defense industry.

Conclusion

In conclusion, evaluating the performance of anti-corrosion coatings on defense materials is an essential service that ensures your equipment remains operational even under extreme conditions. By partnering with Eurolab, you can rely on our expert analysts and state-of-the-art facilities to evaluate your coating solutions accurately and provide actionable insights for optimizing their performance.

As a trusted leader in laboratory services, Eurolab understands the importance of accuracy, reliability, and compliance when it comes to defense materials. Contact us today to discover how we can help you protect your military assets with confidence.

Why Choose Eurolab?

At Eurolab, our mission is simple provide uncompromising quality and unwavering dedication to helping businesses like yours make informed decisions about anti-corrosion coatings for their critical defense equipment. Our team of experts is committed to delivering accurate results that meet the most stringent industry standards.

Experience the difference with Eurolabs unrivaled expertise and state-of-the-art facilities, specifically designed to handle the unique demands of evaluating anti-corrosion coatings on defense materials. Trust us to ensure your equipment meets the highest levels of performance, reliability, and safety every time.