Evaluating the performance of life-support systems under pressure differential testing

Evaluating the Performance of Life-Support Systems Under Pressure Differential Testing A Crucial Service for Businesses

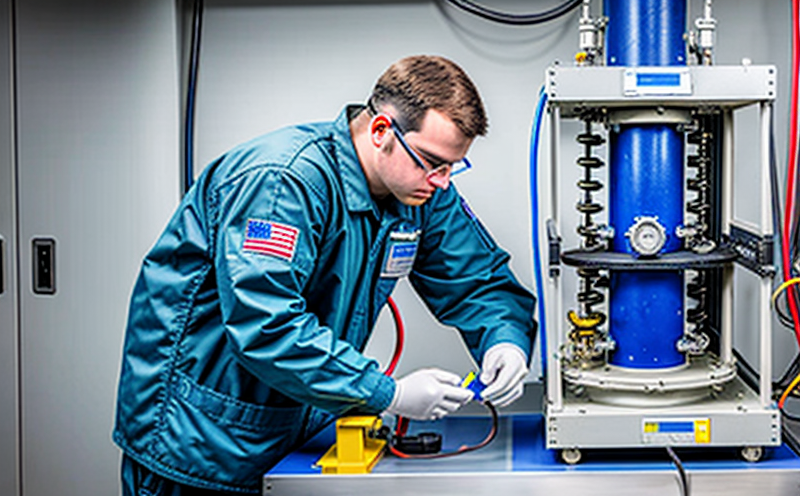

In todays fast-paced industrial landscape, businesses are constantly seeking innovative ways to ensure the reliability and efficiency of their life-support systems. One critical aspect of maintaining these systems is conducting pressure differential testing, a laboratory service that evaluates their performance under various conditions. At Eurolab, we offer this essential service, helping companies optimize their equipment and minimize downtime.

What is Pressure Differential Testing?

Pressure differential testing involves subjecting life-support systems to varying levels of pressure to assess their ability to withstand real-world conditions. This rigorous process simulates the stresses that these systems encounter in industrial environments, allowing manufacturers and operators to identify potential weaknesses and areas for improvement. By evaluating the performance of life-support systems under pressure differential testing, businesses can ensure they meet regulatory requirements, maintain product quality, and reduce the risk of equipment failure.

Why is Pressure Differential Testing Essential?

Conducting pressure differential testing on life-support systems has numerous benefits that make it a crucial service for any business. Here are some key advantages

Improved Equipment Reliability Regular testing helps identify potential issues before they cause system failures, reducing downtime and increasing overall efficiency.

Enhanced Safety By evaluating the performance of life-support systems under pressure differential testing, businesses can minimize the risk of equipment failure, which is critical in industries where safety is paramount.

Compliance with Regulatory Requirements Pressure differential testing ensures that life-support systems meet industry standards and regulatory requirements, reducing the risk of non-compliance and associated fines.

Increased Product Quality By optimizing equipment performance through regular testing, businesses can improve product quality, leading to increased customer satisfaction and loyalty.

Reduced Maintenance Costs Identifying potential issues early on allows for proactive maintenance, reducing the need for costly repairs and replacements.

Key Benefits of Pressure Differential Testing

Here are some key benefits of pressure differential testing in bullet points

Prevents Equipment Failure Regular testing helps identify potential weaknesses, preventing equipment failure and associated downtime.

Improves Safety By evaluating system performance under real-world conditions, businesses can minimize the risk of accidents and injuries.

Enhances Compliance Pressure differential testing ensures that life-support systems meet regulatory requirements, reducing the risk of non-compliance and associated fines.

Increases Product Quality Optimizing equipment performance through regular testing leads to improved product quality, increased customer satisfaction, and loyalty.

Reduces Maintenance Costs Identifying potential issues early on allows for proactive maintenance, reducing the need for costly repairs and replacements.

QA Section

Here are some frequently asked questions about pressure differential testing

Q What is the purpose of pressure differential testing?

A Pressure differential testing evaluates the performance of life-support systems under various conditions to identify potential weaknesses and areas for improvement.

Q Why is regular testing necessary?

A Regular testing helps prevent equipment failure, improves safety, enhances compliance with regulatory requirements, increases product quality, and reduces maintenance costs.

Q How can I schedule a pressure differential test at Eurolab?

A To schedule a pressure differential test, please contact us through our website or by submitting an inquiry. We will be happy to assist you in setting up a testing schedule that meets your needs.

Q What types of life-support systems are eligible for pressure differential testing?

A Pressure differential testing is available for a wide range of life-support systems, including but not limited to air compressors, pumps, and valves. Please contact us to determine if your equipment is suitable for this service.

Q How long does a typical pressure differential test take?

A The duration of a pressure differential test varies depending on the type of equipment being tested and the scope of the testing. Typically, tests can last anywhere from a few hours to several days.

Conclusion

In conclusion, evaluating the performance of life-support systems under pressure differential testing is an essential service that helps businesses ensure the reliability and efficiency of their equipment. At Eurolab, we offer this critical service, providing companies with the tools they need to optimize their life-support systems and minimize downtime. By choosing our laboratory services, you can rest assured that your equipment will meet regulatory requirements, ensuring a safer and more productive work environment for your employees.

Get in Touch

To learn more about our pressure differential testing service or to schedule a test, please submit an inquiry through our website. Our team of experts is here to help you navigate the process and ensure that your life-support systems are performing optimally.