Evaluating the performance of shock-resistant coatings and materials in defense equipment

Evaluating the Performance of Shock-Resistant Coatings and Materials in Defense Equipment A Critical Service for Businesses

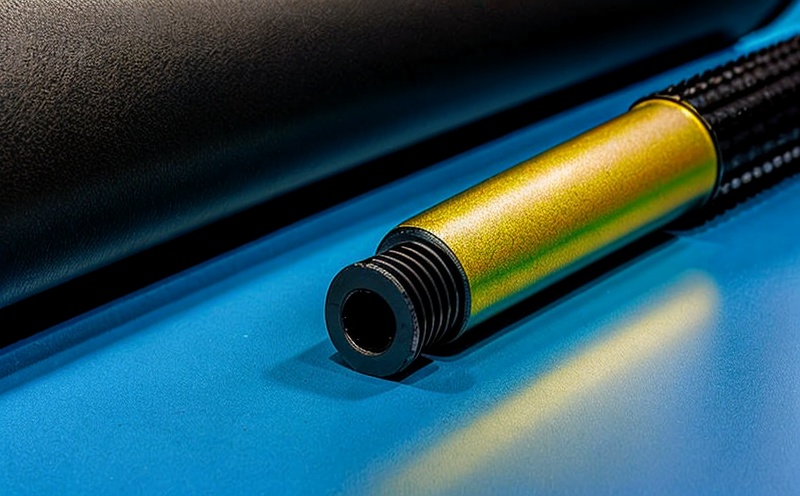

In todays fast-paced and ever-evolving defense industry, military equipment is subjected to extreme temperatures, harsh environments, and intense physical forces that can compromise its performance and longevity. To mitigate these risks, defense manufacturers rely on advanced coatings and materials that can withstand the rigors of combat and provide reliable protection for personnel and assets. However, verifying the effectiveness of these coatings and materials requires specialized expertise and state-of-the-art testing facilities.

This is where Eurolab comes in a leading laboratory service provider offering comprehensive evaluation services for shock-resistant coatings and materials in defense equipment. In this article, we will delve into the importance of evaluating the performance of these critical components, highlight the advantages of our laboratory services, and address common questions and concerns from potential clients.

The Importance of Evaluating Shock-Resistant Coatings and Materials

Shock-resistant coatings and materials are a crucial component of modern defense equipment, playing a vital role in ensuring the safety and effectiveness of military assets. These materials must be able to withstand extreme temperatures, impact forces, and other environmental stressors without compromising their performance or structural integrity.

Evaluating the performance of shock-resistant coatings and materials is essential for several reasons

Ensures Equipment Reliability By verifying the effectiveness of these coatings and materials, defense manufacturers can ensure that their equipment performs reliably in harsh environments, reducing downtime and minimizing the risk of equipment failure.

Protects Personnel Shock-resistant coatings and materials help protect personnel from injury or harm by preventing damage to equipment and infrastructure.

Enhances Performance By optimizing the performance of shock-resistant coatings and materials, defense manufacturers can improve the overall efficiency and effectiveness of their equipment.

Advantages of Eurolabs Laboratory Services

Eurolab offers a range of laboratory services designed to evaluate the performance of shock-resistant coatings and materials in defense equipment. Our expert team uses state-of-the-art testing facilities and equipment to provide comprehensive and accurate results. The advantages of our laboratory services include

Comprehensive Testing Our laboratory services cover a wide range of tests, including impact testing, thermal cycling, and environmental exposure.

Expert Analysis Our experienced team provides in-depth analysis and reporting on the performance of shock-resistant coatings and materials.

Customized Solutions We work closely with clients to develop customized testing protocols that meet their specific needs and requirements.

Quick Turnaround Times Our laboratory services are designed to provide fast turnaround times, ensuring that clients receive results quickly and efficiently.

Key Benefits of Evaluating Shock-Resistant Coatings and Materials

Evaluating the performance of shock-resistant coatings and materials in defense equipment offers numerous benefits for businesses. Some of the key advantages include

Improved Equipment Reliability By verifying the effectiveness of these coatings and materials, manufacturers can ensure that their equipment performs reliably in harsh environments.

Reduced Maintenance Costs Regular evaluation of shock-resistant coatings and materials can help reduce maintenance costs by identifying potential issues before they become major problems.

Enhanced Safety Evaluating the performance of these coatings and materials helps protect personnel from injury or harm by preventing damage to equipment and infrastructure.

Increased Efficiency By optimizing the performance of shock-resistant coatings and materials, manufacturers can improve the overall efficiency and effectiveness of their equipment.

QA Frequently Asked Questions

What types of testing do you offer for shock-resistant coatings and materials?

We provide a range of tests, including impact testing, thermal cycling, environmental exposure, and more.

How long does it take to receive results from your laboratory services?

Our laboratory services are designed to provide fast turnaround times, typically within 1-3 weeks depending on the scope of work.

Can you develop customized testing protocols for our specific needs?

Yes, we work closely with clients to develop customized testing protocols that meet their unique requirements and specifications.

Do you have experience working with defense manufacturers?

Yes, Eurolab has extensive experience working with defense manufacturers and understands the specific challenges and requirements of this industry.

Conclusion

Evaluating the performance of shock-resistant coatings and materials in defense equipment is a critical service that helps ensure the reliability, safety, and effectiveness of military assets. Eurolabs laboratory services offer comprehensive testing and expert analysis to provide accurate results and support informed decision-making for businesses operating in the defense sector. By partnering with us, you can trust that your equipment meets the highest standards of performance and protection.

Dont compromise on the reliability and safety of your equipment choose Eurolab for all your shock-resistant coating and material evaluation needs. Contact us today to learn more about our laboratory services and how we can support your business goals.