Evaluating the robustness of battery cells and packs against physical damage

Evaluating the Robustness of Battery Cells and Packs against Physical Damage A Crucial Service for Businesses

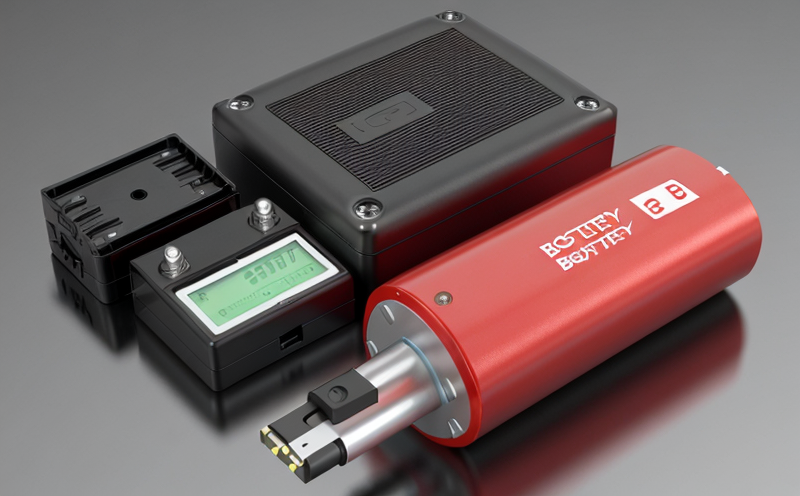

In todays world, batteries are an essential component in a wide range of industries, from renewable energy to electric vehicles and consumer electronics. The increasing demand for reliable and efficient battery systems has led to a growing concern about their safety and durability. One critical aspect that often gets overlooked is the robustness of battery cells and packs against physical damage. At Eurolab, we understand the significance of evaluating the resistance of batteries to various types of physical stress, and our laboratory service is designed to help businesses ensure the reliability and performance of their battery systems.

The Importance of Evaluating Robustness

Physical damage can compromise the safety and functionality of battery cells and packs. Over-discharge, over-charge, impact, crushing, or other forms of mechanical stress can lead to reduced capacity, shortened lifespan, or even catastrophic failures. These issues can result in costly downtime, equipment damage, and reputational harm for businesses.

To mitigate these risks, it is essential to evaluate the robustness of battery cells and packs against physical damage. This process involves subjecting the batteries to various tests that simulate real-world conditions, such as drop testing, crushing, and vibration. By identifying potential weaknesses and vulnerabilities, businesses can take proactive measures to prevent accidents and ensure compliance with regulatory requirements.

Advantages of Using Eurolabs Robustness Evaluation Service

Our robustness evaluation service offers numerous benefits for businesses, including

Improved Safety Identify potential hazards and risks associated with physical damage, ensuring the safety of people, equipment, and property.

Enhanced Reliability Validate the performance and durability of battery cells and packs under various stress conditions, reducing the likelihood of failures and downtime.

Increased Efficiency Optimize battery design and manufacturing processes by identifying areas for improvement and developing more robust materials and configurations.

Compliance with Regulations Meet industry standards and regulatory requirements, such as those set by UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission).

Cost Savings Reduce the financial impact of accidents, equipment damage, and reputational harm by identifying and addressing potential issues early on.

Key Benefits

Our robustness evaluation service provides several key benefits that can help businesses achieve their goals

Comprehensive Testing Our team conducts a range of tests to simulate real-world conditions, including

Drop testing Evaluates the batterys ability to withstand impact and drop-induced damage.

Crushing Tests the batterys resistance to compression and crushing forces.

Vibration Simulates the effects of vibration on battery performance and durability.

Customized Solutions We work with businesses to develop tailored testing protocols that meet their specific needs and requirements.

Timely Results Our experienced team provides prompt and accurate results, allowing businesses to make informed decisions quickly.

Expert Analysis Our experts interpret test data and provide actionable recommendations for improving battery design, manufacturing, and performance.

QA Frequently Asked Questions

Q What types of batteries can be tested?

A We can evaluate the robustness of a wide range of battery cells and packs, including lithium-ion, nickel-cadmium, lead-acid, and other chemistries.

Q How long does the testing process take?

A The duration of the testing process varies depending on the type and scope of the tests. Our team will work with you to develop a customized testing plan that meets your needs and timelines.

Q What types of physical damage can be simulated in the lab?

A We can simulate various forms of physical stress, including impact, crushing, vibration, over-discharge, and over-charge.

Q Are the test results confidential?

A Yes, all test data and results are kept confidential to protect your businesss intellectual property and competitive advantage.

Conclusion

Evaluating the robustness of battery cells and packs against physical damage is a critical aspect of ensuring their safety, reliability, and performance. At Eurolab, we offer a comprehensive laboratory service designed to help businesses identify potential weaknesses and vulnerabilities in their battery systems. By leveraging our expertise and state-of-the-art testing facilities, you can make informed decisions about your battery design, manufacturing, and deployment strategies.

Dont wait until its too late contact us today to learn more about how Eurolabs robustness evaluation service can help you mitigate the risks associated with physical damage and ensure the success of your business.

-

Testing battery safety under international IEC 62133 safety standards

-

Verifying battery protection against electrical, mechanical, and environmental hazards

-

Simulating short circuit, overcharge, and thermal abuse conditions for compliance

-

Assessing battery performance under various stress tests for IEC 62133

-

Measuring the risk of fire, explosion, or chemical leakage during compliance testing

-

Testing for compliance with IEC 62133 for consumer electronics batteries

-

Ensuring safety compliance for batteries used in medical devices and wearables

-

IEC 62133 compliance testing for batteries used in electric vehicles

-

Determining battery safety during overcharge, deep discharge, and short-circuit scenarios

-

Assessing battery design features to meet IEC 62133 safety requirements

-

Simulating abusive conditions to ensure compliance with IEC 62133

-

Testing for safe operation and disposal of batteries according to IEC standards

-

IEC 62133 compliance testing for batteries in energy storage and industrial applications

-

Evaluating safety features in battery management systems for IEC compliance

-

IEC 62133 testing for batteries used in aviation and aerospace

-

Assessing the thermal stability of batteries under compliance testing conditions

-

Verifying battery casing and packaging against impact and puncture risks

-

Measuring voltage, current, and temperature limits during compliance testing

-

Testing for compliance with international battery safety standards for transport