Fluid flow testing for medical devices used in surgical procedures

The Crucial Role of Fluid Flow Testing in Ensuring Medical Device Safety Why Eurolab is the Go-To Laboratory Service

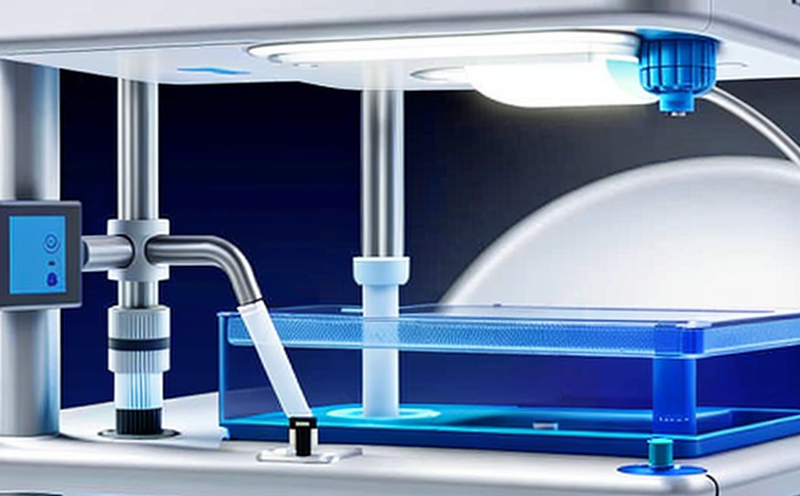

In the world of medical devices used in surgical procedures, reliability and efficacy are paramount. One critical aspect that ensures these devices function as intended is fluid flow testing. This laboratory service, provided by Eurolab, plays a pivotal role in guaranteeing the safety and effectiveness of medical devices by simulating real-world conditions to test their performance under various pressure ranges.

As manufacturers strive for innovation and precision, they must also adhere to stringent regulatory requirements. Fluid flow testing helps them meet these standards while minimizing product recalls and ensuring patient safety. In this article, well delve into the importance of fluid flow testing for medical devices used in surgical procedures, highlighting its advantages, benefits, and why Eurolab is the preferred choice for laboratory services.

What is Fluid Flow Testing?

Fluid flow testing involves simulating various pressure ranges to test the performance of medical devices used in surgical procedures. This laboratory service is designed to evaluate how these devices handle fluid dynamics under different conditions. By doing so, manufacturers can ensure their products meet regulatory requirements and function as intended during actual use.

Advantages of Fluid Flow Testing for Medical Devices Used in Surgical Procedures

Eurolabs expert team understands the importance of fluid flow testing in ensuring medical device safety. Here are some key benefits

Reduced Risk of Product Failure By simulating real-world conditions, manufacturers can identify potential flaws and address them before product launch, minimizing the risk of product failure and associated costs.

Compliance with Regulatory Requirements Fluid flow testing helps manufacturers meet stringent regulatory requirements, reducing the likelihood of product recalls and associated financial losses.

Improved Patient Safety By ensuring medical devices function as intended, fluid flow testing contributes to improved patient safety and reduced morbidity and mortality rates.

Enhanced Product Reliability Manufacturers can optimize their products performance by identifying areas for improvement, resulting in enhanced reliability and customer satisfaction.

Key Benefits of Fluid Flow Testing

Some key benefits of using Eurolabs fluid flow testing services include

Accurate Pressure Measurement Our state-of-the-art equipment ensures accurate pressure measurement, giving manufacturers confidence in their products performance.

Real-World Simulation By simulating real-world conditions, we help manufacturers identify potential issues and optimize their products for maximum efficiency.

Expert Analysis Our experienced team provides expert analysis and recommendations to ensure manufacturers meet regulatory requirements and improve product reliability.

Cost-Effective Solution Fluid flow testing is a cost-effective solution compared to actual clinical trials, reducing the financial burden on manufacturers.

QA Frequently Asked Questions About Fluid Flow Testing for Medical Devices Used in Surgical Procedures

Here are some frequently asked questions about fluid flow testing

Q What is fluid flow testing?

A Fluid flow testing involves simulating various pressure ranges to test the performance of medical devices used in surgical procedures.

Q Why is fluid flow testing essential for medical device manufacturers?

A Fluid flow testing ensures medical devices function as intended, meeting regulatory requirements and reducing product failure risk.

Q What are the benefits of using Eurolabs fluid flow testing services?

A Our services offer accurate pressure measurement, real-world simulation, expert analysis, and cost-effectiveness.

Conclusion

In conclusion, fluid flow testing for medical devices used in surgical procedures is a critical laboratory service that ensures product safety, efficacy, and regulatory compliance. By partnering with Eurolab, manufacturers can

Ensure Regulatory Compliance Meet stringent regulatory requirements to minimize the risk of product recalls.

Reduce Product Failure Risk Identify potential flaws before product launch, reducing associated costs.

Improve Patient Safety Contribute to improved patient safety and reduced morbidity and mortality rates.

At Eurolab, our team is committed to providing expert laboratory services that meet the unique needs of medical device manufacturers. Contact us today to learn more about how we can support your business and ensure the safe and effective use of your products.