Friction coefficient evaluation

Unlocking Smooth Operations The Crucial Role of Friction Coefficient Evaluation in Industry

In the world of manufacturing and production, even the smallest variables can have a significant impact on efficiency, safety, and profitability. One such critical aspect often overlooked is the friction coefficient a measure of the force required to start or maintain motion between two surfaces in contact. Understanding and evaluating the friction coefficient is essential for businesses seeking to optimize their operations, minimize costs, and ensure compliance with regulatory standards.

At Eurolab, our team of experts offers Friction Coefficient Evaluation as a laboratory service that helps companies like yours make informed decisions about material selection, equipment maintenance, and production processes. By harnessing the power of friction coefficient analysis, you can unlock smoother operations, reduce downtime, and stay ahead of the competition.

Why is Friction Coefficient Evaluation Important for Businesses?

Friction coefficient evaluation is a critical aspect of various industries, including

Manufacturing Ensures optimal material selection and equipment maintenance, reducing production costs and improving product quality.

Aerospace Critical in ensuring the safety and performance of aircraft components, engines, and systems.

Automotive Essential for designing and testing vehicle brakes, clutches, and other moving parts.

Industrial Equipment Helps prevent wear and tear on machinery, reducing maintenance costs and increasing productivity.

Advantages of Using Friction Coefficient Evaluation

Eurolabs Friction Coefficient Evaluation service offers numerous benefits to businesses, including

Benefits for Manufacturers

Improved Product Quality Accurate friction coefficient measurements ensure optimal material selection and processing conditions, leading to better product quality.

Reduced Production Costs By selecting materials with the right friction properties, manufacturers can minimize production costs associated with rework, repairs, or replacements.

Increased Efficiency Smooth operations and reduced downtime mean more productive hours and increased overall efficiency.

Benefits for Aerospace and Defense

Enhanced Safety Accurate friction coefficient measurements ensure the safe operation of critical aircraft systems, engines, and components.

Improved Performance Optimal friction properties enhance aircraft performance, maneuverability, and responsiveness.

Compliance with Regulations Eurolabs Friction Coefficient Evaluation ensures compliance with industry-specific regulations and standards.

Benefits for Automotive

Improved Brake Performance Accurate friction coefficient measurements ensure optimal brake design and functionality.

Enhanced Safety Smooth braking operations reduce the risk of accidents, ensuring safer roads and communities.

Increased Fuel Efficiency Optimal friction properties lead to reduced fuel consumption and lower emissions.

Benefits for Industrial Equipment Operators

Reduced Maintenance Costs Regular friction coefficient measurements help prevent wear and tear on machinery, reducing maintenance costs.

Increased Productivity Smooth operations and reduced downtime mean more productive hours and increased overall efficiency.

Extended Equipment Life Accurate friction coefficient measurements ensure optimal equipment performance, extending its lifespan.

QA Friction Coefficient Evaluation with Eurolab

Q What is the purpose of Friction Coefficient Evaluation?

A The primary goal of Friction Coefficient Evaluation is to measure and understand the force required for surfaces in contact to start or maintain motion. This information helps businesses optimize material selection, equipment maintenance, and production processes.

Q How does Eurolabs Friction Coefficient Evaluation service differ from others?

A Our team of experts uses advanced laboratory techniques and equipment to provide accurate and reliable friction coefficient measurements. We offer customized testing plans tailored to your specific needs and industry requirements.

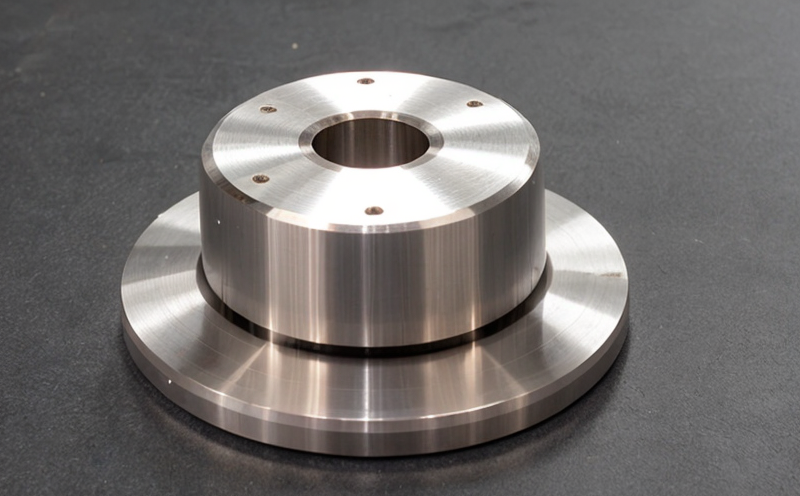

Q What types of samples can be tested for friction coefficient evaluation?

A Eurolabs Friction Coefficient Evaluation service is suitable for various materials, including metals, polymers, ceramics, and composites.

Q How long does the friction coefficient evaluation process take?

A The duration of our testing services varies depending on the type of sample and testing requirements. Our team will work closely with you to determine the most efficient testing schedule.

Q What kind of results can I expect from Eurolabs Friction Coefficient Evaluation service?

A Youll receive detailed, accurate measurements of your samples friction coefficient, along with expert analysis and recommendations for optimizing material selection, equipment maintenance, or production processes.

Conclusion

Friction coefficient evaluation is a critical aspect of various industries, offering numerous benefits to businesses seeking to optimize operations, reduce costs, and ensure compliance with regulatory standards. At Eurolab, our team of experts offers Friction Coefficient Evaluation as a laboratory service that helps companies like yours make informed decisions about material selection, equipment maintenance, and production processes.

Dont let friction-related issues compromise your businesss efficiency, safety, or profitability. Contact us today to learn more about Eurolabs Friction Coefficient Evaluation service and discover how we can help you unlock smoother operations and stay ahead of the competition.