Gloss measurement in coatings with varying thickness

The Importance of Gloss Measurement in Coatings with Varying Thickness Why Your Business Needs This Laboratory Service

As a manufacturer or supplier of coatings, you understand the significance of ensuring that your products meet the desired level of gloss and appearance. However, measuring gloss can be a complex task, especially when dealing with varying thickness levels. Thats where Eurolab comes in our laboratory services specialize in providing accurate and reliable gloss measurements for coatings with diverse thicknesses.

What is Gloss Measurement in Coatings with Varying Thickness?

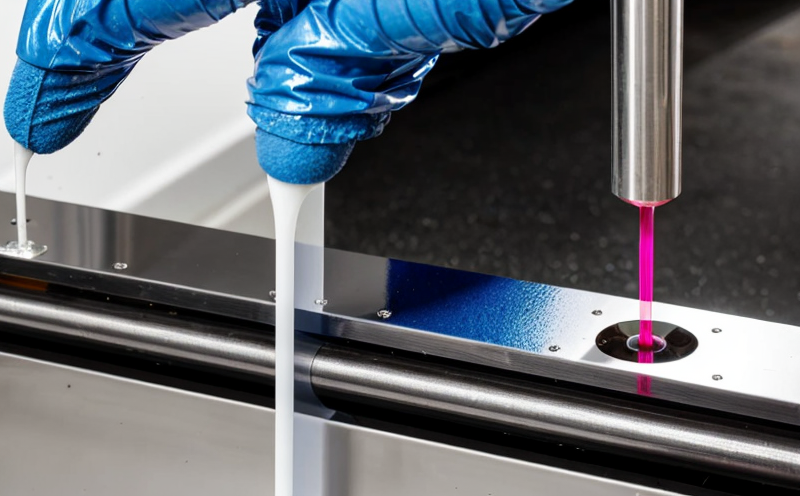

Gloss measurement in coatings with varying thickness refers to the process of evaluating the specular reflection (or shine) of a coating surface. This is typically measured using specialized equipment, such as glossmeters, which provide precise readings of the coatings reflectivity. In coatings with varying thickness, it can be challenging to achieve consistent results due to differences in layer uniformity and material composition.

Why is Gloss Measurement in Coatings with Varying Thickness Essential for Businesses?

Measuring gloss in coatings with varying thickness is crucial for several reasons

Quality Control Ensuring that your products meet the desired level of gloss is essential for maintaining quality control standards. By measuring gloss, you can identify any issues related to material composition, application techniques, or equipment calibration.

Compliance with Industry Standards Many industries, such as automotive, aerospace, and construction, have strict regulations regarding coating appearance and performance. By measuring gloss, you can ensure that your products comply with these standards.

Cost Savings Measuring gloss helps to identify issues early on, reducing the need for costly rework or repairs. This not only saves time but also reduces waste and increases productivity.

Improved Customer Satisfaction By providing high-quality coatings with consistent appearance, you can improve customer satisfaction and build trust in your brand.

Advantages of Using Gloss Measurement in Coatings with Varying Thickness

Using gloss measurement services from Eurolab offers numerous benefits for businesses

Accurate Results Our laboratory uses state-of-the-art equipment to provide precise and reliable gloss measurements.

Increased Efficiency By outsourcing gloss measurement, you can focus on other aspects of your business while ensuring that your products meet quality standards.

Cost-Effective Measuring gloss with our services is often more cost-effective than investing in internal equipment or personnel.

Expertise and Knowledge Our laboratory has extensive experience working with various coating types and materials, providing valuable insights for optimizing product performance.

Key Benefits of Eurolabs Gloss Measurement Services

Our laboratory offers a range of benefits that set us apart from other service providers

Wide Range of Coating Types We specialize in measuring gloss on various coatings, including paint, varnish, and lacquer.

Customized Solutions Our team works closely with clients to develop tailored measurement protocols that meet specific industry requirements.

Fast Turnaround Times We understand the importance of timely results and strive to deliver measurements within a few hours or days, depending on your needs.

Secure Data Management All data is stored securely and confidentially, ensuring that sensitive information remains protected.

QA Section

Here are some frequently asked questions about gloss measurement in coatings with varying thickness

Q What types of coatings can be measured for gloss?

A Eurolabs laboratory services cater to a wide range of coating types, including paint, varnish, lacquer, and more. We also work with various substrates and materials.

Q How do you measure gloss in coatings with varying thickness?

A Our team uses specialized equipment, such as glossmeters, to provide accurate readings of the coatings reflectivity. We adapt our measurement protocols to accommodate different coating types and thickness levels.

Q Can I outsource gloss measurement if my company already has internal equipment?

A Yes! Measuring gloss with Eurolabs services can be a cost-effective alternative or supplement to your existing equipment. Our team can help you identify areas for improvement and provide expert insights for optimizing product performance.

Q How do I ensure the accuracy of gloss measurements?

A We take every precaution to ensure accurate results, including using calibrated equipment, adhering to strict quality control protocols, and maintaining a clean and controlled laboratory environment.

Q Can Eurolab provide customized solutions for my specific industry or coating type?

A Absolutely! Our team has extensive experience working with various industries and coatings. We develop tailored measurement protocols that meet your unique requirements and standards.

Conclusion

Measuring gloss in coatings with varying thickness is a critical aspect of ensuring product quality, compliance with industry standards, and customer satisfaction. By partnering with Eurolabs laboratory services, you can benefit from accurate results, increased efficiency, and cost savings. Contact us today to learn more about how our gloss measurement services can support your business goals.

Our team is dedicated to providing exceptional service and supporting the success of your company. With our expertise and state-of-the-art equipment, we can help you achieve consistent quality and improve customer satisfaction.