Heat sink contact testing

The Importance of Heat Sink Contact Testing Ensuring Efficient Thermal Management in Electronics

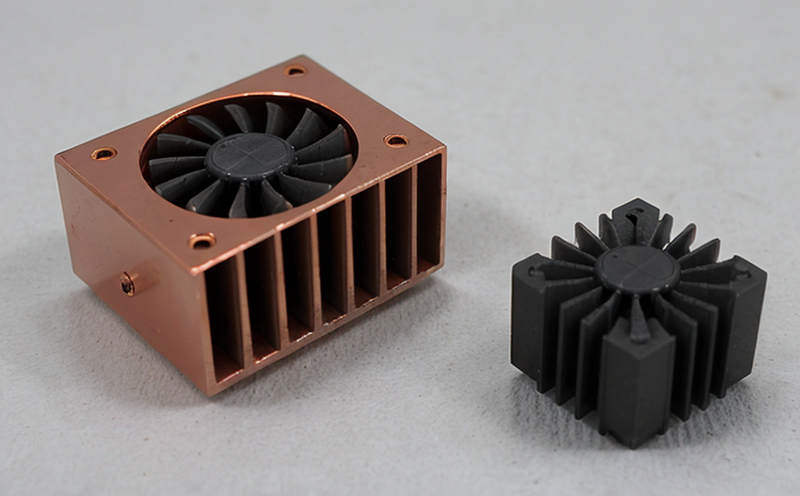

In the world of electronics, thermal management is a critical aspect that can make or break the performance and reliability of electronic devices. One key component in this process is the heat sink, which plays a vital role in dissipating heat away from sensitive components. However, ensuring proper contact between the heat sink and the device its cooling can be a challenge. This is where Heat Sink Contact Testing comes in a laboratory service provided by Eurolab that helps businesses ensure their devices meet thermal management requirements.

What is Heat Sink Contact Testing?

Heat Sink Contact Testing is a laboratory-based service that evaluates the thermal interface between a heat sink and an electronic device. It involves using specialized equipment to measure the thermal resistance of the contact, providing critical data on how effectively the heat sink is dissipating heat from the device. This testing helps identify any potential issues with the thermal interface, allowing businesses to make informed decisions about design improvements or material substitutions.

Why is Heat Sink Contact Testing Essential for Businesses?

In todays competitive electronics market, ensuring that devices meet thermal management requirements is crucial for several reasons

Reduced Risk of Component Failure Inadequate heat dissipation can lead to component failure, which can result in costly product recalls and damage to a companys reputation.

Improved Thermal Performance Heat Sink Contact Testing enables businesses to optimize their designs, ensuring that devices operate within safe temperature ranges.

Increased Efficiency Proper thermal management helps reduce energy consumption, leading to lower operational costs and enhanced sustainability.

Compliance with Industry Standards Many industries, such as aerospace and automotive, have strict thermal management requirements. Heat Sink Contact Testing ensures compliance with these standards, reducing the risk of regulatory issues.

Competitive Advantage Companies that prioritize thermal management can differentiate themselves in the market, attracting customers who value reliable and efficient products.

Key Benefits of Heat Sink Contact Testing

Eurolabs Heat Sink Contact Testing service offers numerous benefits for businesses

Accurate Thermal Interface Measurements Our expert technicians use advanced equipment to measure thermal resistance with high accuracy.

Comprehensive Data Analysis We provide detailed reports on thermal interface performance, enabling informed design decisions and optimization strategies.

Customized Testing Solutions Eurolab adapts its testing protocols to meet the specific needs of each client, ensuring that their devices are tested under relevant conditions.

Rapid Turnaround Times Our efficient testing processes minimize downtime, allowing businesses to quickly respond to market demands.

Expert Consultation and Support Our experienced engineers offer guidance on improving thermal management in electronic devices, helping clients optimize their designs for maximum efficiency.

Frequently Asked Questions

Q What types of heat sinks can be tested?

A Eurolabs Heat Sink Contact Testing service is designed to accommodate various types of heat sinks, including copper, aluminum, and ceramic-based materials.

Q Can I request custom testing protocols?

A Yes. Our team will work with you to develop a tailored testing plan that meets your specific requirements and ensures relevant conditions are applied.

Q How long does the testing process typically take?

A Turnaround times vary depending on the complexity of the test, but most tests can be completed within 2-5 working days.

Q Do I need to provide any specialized equipment or materials?

A No. Eurolab provides all necessary equipment and materials for the testing process.

Q Can I receive a report detailing the thermal interface performance of my device?

A Yes. Our comprehensive reports include detailed data on thermal resistance, providing valuable insights into your devices thermal management performance.

Conclusion

In conclusion, Heat Sink Contact Testing is an essential service for businesses seeking to ensure their electronic devices meet thermal management requirements. By evaluating the thermal interface between a heat sink and an electronic device, Eurolab helps companies identify areas for improvement and optimize their designs for maximum efficiency. With our expert consultation, customized testing solutions, and rapid turnaround times, we empower businesses to take control of their thermal management needs and stay ahead in the competitive electronics market.

Contact Eurolab today to learn more about how Heat Sink Contact Testing can benefit your business.