Impact of sterilization on the mechanical properties of medical devices

The Critical Impact of Sterilization on Medical Devices Ensuring Reliability and Safety through Eurolabs Expertise

In the intricate world of medical device manufacturing, ensuring the reliability and safety of products is paramount. One crucial aspect that often goes unaddressed is the impact of sterilization on the mechanical properties of these devices. Sterilization, a process intended to eliminate pathogens and contaminants from equipment, can inadvertently compromise the materials strength, durability, and overall performance. Understanding this phenomenon is essential for manufacturers, as it directly affects patient safety and device efficacy.

What is the Impact of Sterilization on Mechanical Properties?

Sterilization methods, such as ethylene oxide (EO) gas sterilization or gamma radiation, are designed to eliminate microbial life from medical devices. However, these processes can also alter the materials molecular structure, causing changes in its mechanical properties. These alterations can manifest as reduced tensile strength, increased brittleness, or altered fatigue resistance.

Advantages of Understanding and Mitigating Sterilization Impact

Recognizing the effects of sterilization on medical devices offers numerous benefits for manufacturers

Improved Patient Safety By understanding how sterilization affects device performance, manufacturers can develop safer products that minimize the risk of adverse events.

Enhanced Device Efficacy Knowing the mechanical property changes induced by sterilization enables designers to create devices that meet or exceed regulatory standards while ensuring optimal functionality.

Cost Savings Manufacturers who comprehend the impact of sterilization can optimize their design and testing processes, reducing the need for costly rework or recalls.

Compliance with Regulatory Requirements By demonstrating an understanding of sterilization effects on mechanical properties, manufacturers can more easily meet regulatory demands and avoid associated penalties.

Key Benefits of Utilizing Eurolabs Expertise

Eurolab offers a comprehensive laboratory service that helps manufacturers grasp the complex relationship between sterilization and mechanical properties. Our specialized team provides

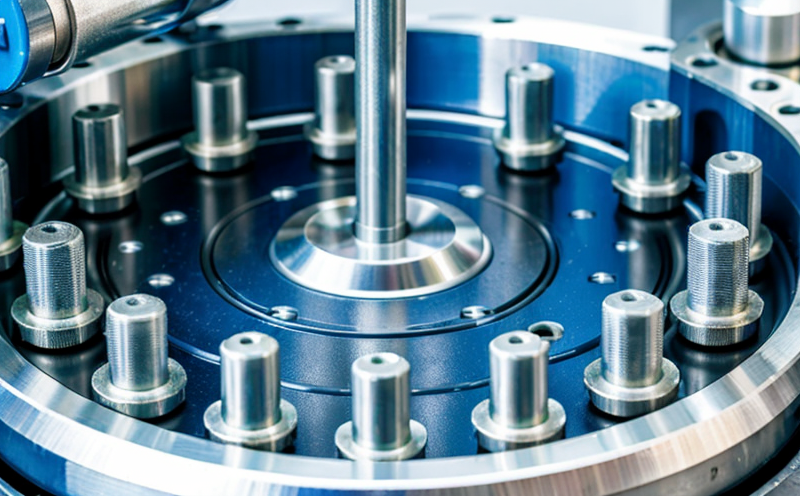

Detailed Analysis State-of-the-art testing equipment and experienced technicians enable thorough assessments of material properties before, during, and after sterilization.

Customized Solutions Eurolab develops tailored testing protocols to simulate real-world sterilization conditions, providing manufacturers with actionable insights for design optimization.

Collaborative Approach Our experts work closely with clients to integrate findings into their product development processes, ensuring seamless transition from laboratory to production.

Frequently Asked Questions (FAQs)

Q What types of medical devices are most susceptible to sterilization-induced mechanical property changes?

A Devices made from polymers, metals, or other materials that undergo significant structural changes during sterilization are at highest risk.

Q Can Eurolab assist with design modifications to mitigate the effects of sterilization on my product?

A Yes, our team provides expert consultation and customized testing protocols to help manufacturers adapt their designs for optimal performance post-sterilization.

Q How does Eurolab ensure accurate and reliable test results?

A Our laboratory adheres to strict quality control procedures, utilizes calibrated equipment, and employs experienced technicians trained in advanced testing methodologies.

Q Can I request a customized testing package tailored to my specific product needs?

A Absolutely! Eurolabs flexible service model allows for bespoke testing protocols that cater to individual client requirements.

Conclusion

Understanding the impact of sterilization on medical devices is no longer a luxury it has become an imperative for businesses seeking to guarantee patient safety, device efficacy, and regulatory compliance. By partnering with Eurolab, manufacturers can unlock the full potential of their products while minimizing risks associated with sterilization-induced mechanical property changes.

Dont compromise your products integrity; choose Eurolab as your trusted laboratory partner for comprehensive analysis and expert guidance on the critical relationship between sterilization and medical device performance.