Impact of surface hardness on scratch resistance

The Crucial Role of Surface Hardness in Scratch Resistance Why Your Business Needs to Know

In todays fast-paced and competitive business landscape, ensuring the durability and longevity of your products is paramount. One critical aspect that often gets overlooked is the surface hardness of materials and its impact on scratch resistance. At Eurolab, we specialize in providing laboratory services that help businesses like yours understand the intricacies of material properties and optimize their products for optimal performance.

In this article, well delve into the significance of surface hardness on scratch resistance, exploring its benefits, advantages, and the science behind it. By the end of this comprehensive guide, youll have a deep understanding of why surface hardness is essential for your business and how our laboratory services can help you make informed decisions.

What is Surface Hardness and Scratch Resistance?

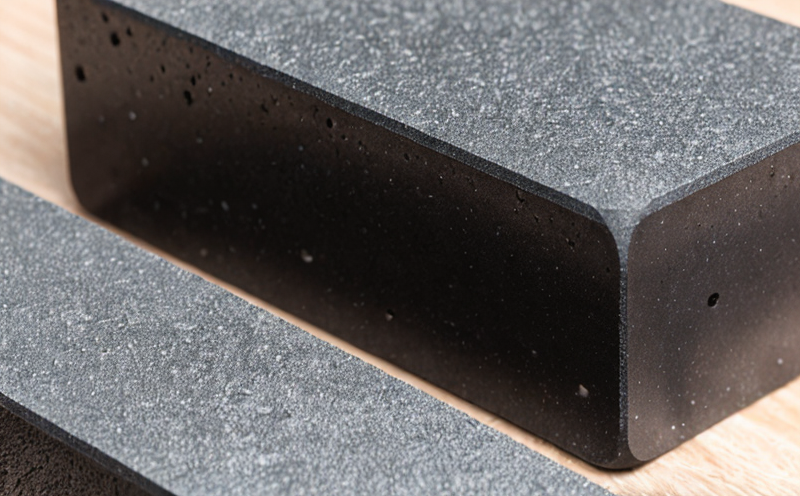

Surface hardness refers to the measure of a materials resistance to scratching or abrasion. It is a critical property that determines how well a material can withstand wear and tear, particularly in high-traffic areas or applications where materials are subject to heavy usage. Scratch resistance, on the other hand, is a measure of a materials ability to resist scratches caused by external forces, such as friction or impact.

The Importance of Surface Hardness on Scratch Resistance

Surface hardness plays a pivotal role in determining scratch resistance. When a material has high surface hardness, it is more resistant to scratches and abrasion. Conversely, materials with low surface hardness are more prone to scratching and wear. The relationship between surface hardness and scratch resistance is complex, involving various factors such as

Material composition

Manufacturing process

Surface finish

Environmental conditions

Advantages of Understanding Impact of Surface Hardness on Scratch Resistance

By understanding the impact of surface hardness on scratch resistance, businesses can reap numerous benefits, including

Improved Product Performance Products with high surface hardness and scratch resistance will perform better in real-world applications, reducing maintenance costs and increasing overall efficiency.

Enhanced Customer Satisfaction Customers expect products to withstand wear and tear; by ensuring your materials have sufficient surface hardness, youll meet their expectations and build trust in your brand.

Reduced Maintenance Costs By minimizing scratches and abrasion, businesses can save on maintenance costs associated with repairing or replacing damaged materials.

Increased Product Lifespan Materials with high surface hardness will last longer, reducing the need for frequent replacements and lowering waste disposal costs.

Benefits of Using Eurolabs Impact of Surface Hardness on Scratch Resistance Services

At Eurolab, our laboratory services provide businesses with a comprehensive understanding of material properties. By using our impact of surface hardness on scratch resistance services, youll benefit from

Accurate Material Characterization Our experts will analyze your materials to determine their surface hardness and scratch resistance, providing actionable insights for optimization.

Customized Solutions Based on the results, well work with you to develop customized solutions that meet your specific needs and requirements.

Improved Product Design By understanding the impact of surface hardness on scratch resistance, youll be able to design products that better withstand wear and tear.

Key Benefits of Impact of Surface Hardness on Scratch Resistance Services

Accurate material characterization

Customized solutions for optimal performance

Reduced maintenance costs

Increased product lifespan

Enhanced customer satisfaction

Improved product design

Compliance with industry standards

Risk mitigation through informed decision-making

Frequently Asked Questions (FAQs)

Q What is the significance of surface hardness on scratch resistance?

A Surface hardness plays a critical role in determining scratch resistance. Materials with high surface hardness are more resistant to scratches and abrasion.

Q How does Eurolabs laboratory service help businesses understand impact of surface hardness on scratch resistance?

A Our experts will analyze your materials, providing accurate characterization and customized solutions for optimal performance.

Q What are the benefits of using Eurolabs services?

A By using our services, youll benefit from accurate material characterization, customized solutions, reduced maintenance costs, increased product lifespan, enhanced customer satisfaction, improved product design, compliance with industry standards, and risk mitigation through informed decision-making.

Conclusion

In conclusion, understanding the impact of surface hardness on scratch resistance is crucial for businesses seeking to optimize their products performance. By leveraging Eurolabs laboratory services, youll gain valuable insights into material properties, enabling you to make informed decisions that drive business success.

Whether youre a manufacturer looking to improve product design or a supplier seeking to meet customer expectations, our impact of surface hardness on scratch resistance services will provide you with the knowledge and expertise needed to succeed in todays competitive market.

Get Started Today

Dont wait any longer to optimize your products for optimal performance. Contact Eurolab today to learn more about our laboratory services and how we can help you achieve your business goals.