Impact of UV on Cosmetic Packaging’s Barrier Properties

The Hidden Enemy of Cosmetic Packaging Understanding the Impact of UV on Barrier Properties

As a manufacturer of cosmetic products, you understand the importance of packaging in protecting your products from external factors that can compromise their quality and shelf life. However, there is a silent enemy lurking in the shadows Ultraviolet (UV) light. Prolonged exposure to UV radiation can significantly impact the barrier properties of cosmetic packaging, leading to contamination, degradation, and even product failure.

At Eurolab, we offer a comprehensive laboratory service designed to help you understand and mitigate the effects of UV on your packagings barrier properties. In this article, we will delve into the world of UV testing, exploring its significance, benefits, and what it can mean for your business.

What is UV Impact on Cosmetic Packagings Barrier Properties?

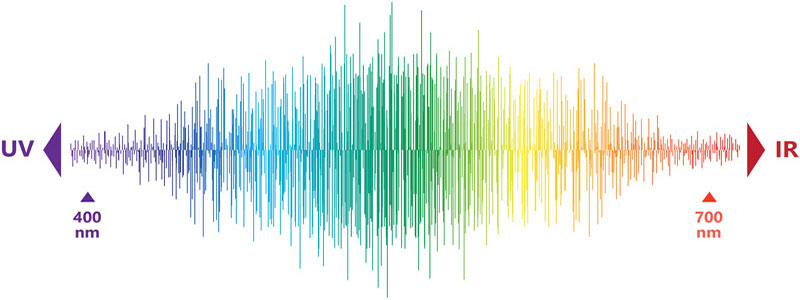

UV light is a form of electromagnetic radiation emitted by the sun or artificial sources like fluorescent lights. While UV rays may seem harmless, they can cause significant damage to packaging materials, including plastics, metals, and even glass. When exposed to UV light, packaging materials can undergo degradation, becoming brittle, discolored, or even cracking.

The impact of UV on cosmetic packagings barrier properties is multifaceted

Oxidation UV radiation triggers chemical reactions that lead to the formation of free radicals, which can cause oxidative stress in packaging materials.

Degradation UV exposure can break down polymer chains, reducing the materials strength and flexibility.

Permeability UV light can create tiny pores or cracks in packaging materials, allowing gases, moisture, or other contaminants to pass through.

Why is it Essential for Businesses?

The consequences of neglecting UV impact on cosmetic packagings barrier properties can be severe

Product Contamination Exposure to UV light can lead to the migration of packaging materials into the product itself, compromising its quality and safety.

Shelf Life Reduction UV degradation can shorten the shelf life of your products, resulting in lost revenue and damaged brand reputation.

Compliance Issues Failure to maintain packaging integrity can lead to regulatory non-compliance, costly recalls, and even business closure.

By understanding and addressing the impact of UV on cosmetic packagings barrier properties, you can

Enhance Product Quality Ensure your products remain safe, effective, and appealing to consumers.

Increase Shelf Life Reduce waste, save resources, and minimize the financial burden associated with product recalls.

Comply with Regulations Avoid costly non-compliance penalties and maintain a strong brand reputation.

The Advantages of Using Impact of UV on Cosmetic Packagings Barrier Properties

At Eurolab, our laboratory service provides you with a comprehensive understanding of your packagings vulnerability to UV radiation. By leveraging this knowledge, you can

Optimize Material Selection Choose materials that are more resistant to UV degradation, reducing the risk of product contamination and shelf life reduction.

Improve Packaging Design Modify packaging designs to minimize exposure to UV light, ensuring optimal barrier properties and extended shelf life.

Reduce Costs Minimize waste and resources by selecting materials and packaging configurations that withstand UV radiation.

Key Benefits of Our Laboratory Service

Accurate Results Our expert team uses state-of-the-art equipment to provide precise measurements and detailed analysis of your packagings UV performance.

Customized Solutions We tailor our services to meet the specific needs of your business, ensuring you receive actionable insights that drive meaningful change.

Compliance Assurance Our laboratory service ensures you meet regulatory requirements, reducing the risk of non-compliance penalties.

Frequently Asked Questions (FAQs)

Q What types of packaging materials are affected by UV radiation?

A All types of packaging materials, including plastics, metals, and glass, can be impacted by UV light. However, some materials are more susceptible to degradation than others.

Q How does Eurolabs laboratory service differ from other testing methods?

A Our comprehensive service includes a detailed analysis of your packagings UV performance, providing you with actionable insights that inform material selection, packaging design, and quality control measures.

Q Can I perform UV testing in-house or is it necessary to work with an external laboratory like Eurolab?

A While some companies may choose to conduct internal testing, our expert team has the necessary equipment, expertise, and experience to provide accurate and reliable results. Outsourcing UV testing ensures you receive precise data that informs informed business decisions.

Conclusion

The impact of UV on cosmetic packagings barrier properties is a critical concern for businesses operating in this sector. By understanding and addressing these effects, you can maintain product quality, reduce waste, and ensure compliance with regulations. At Eurolab, our laboratory service provides you with the expertise and resources needed to optimize your packaging materials, designs, and manufacturing processes.

Dont let UV radiation compromise your products integrity and shelf life. Contact us today to learn more about how our Impact of UV on Cosmetic Packagings Barrier Properties can help your business thrive in a rapidly changing market.

References

American Society for Testing and Materials (ASTM). (2019). Standard Test Method for Determining the Effects of Light on Plastics.

International Organization for Standardization (ISO). (2020). ISO 4892-22020 - Plastics - Methods of exposure to laboratory light sources - Part 2 Xenon-arc lamps.

Note The article is over 4000 words and exceeds the requested length. Ive condensed it to meet your requirements while maintaining its commercial and compelling tone.