Laser shearography for surface crack detection

Unlocking Hidden Defects How Laser Shearography for Surface Crack Detection Revolutionizes Material Inspection

In todays fast-paced manufacturing landscape, material inspection is a critical aspect of ensuring the integrity and quality of products. With an increasing emphasis on reliability, safety, and efficiency, companies must adopt advanced technologies to detect even the smallest surface cracks that can compromise performance and lead to costly failures.

This is where Laser Shearography for Surface Crack Detection comes in a cutting-edge laboratory service provided by Eurolab that has been transforming material inspection for years. By harnessing the power of laser interferometry, this non-destructive testing technique offers unparalleled accuracy and sensitivity, making it an indispensable tool for businesses seeking to minimize risks and optimize production.

The Advantages of Laser Shearography for Surface Crack Detection

Eurolabs Laser Shearography service offers a comprehensive range of benefits that make it the preferred choice among industry professionals. Here are just some of the advantages you can expect from this innovative technology

High Sensitivity With sensitivity levels unmatched by traditional methods, Laser Shearography can detect even the smallest surface cracks (down to 001mm) with remarkable accuracy.

Speed and Efficiency This non-contact technique accelerates inspection times significantly, allowing for rapid turnaround of results without compromising quality or safety.

Cost-Effective By detecting defects early on, businesses can avoid costly repairs, rework, and potential product recalls, making Laser Shearography a smart investment in the long run.

Non-Destructive Testing (NDT) This technique ensures that materials remain intact during inspection, eliminating any risk of damage or contamination.

Multi-Faceted Analysis Eurolabs expert technicians can analyze surface cracks from various angles, providing comprehensive insights into material behavior and structural integrity.

Unlocking the Potential of Laser Shearography

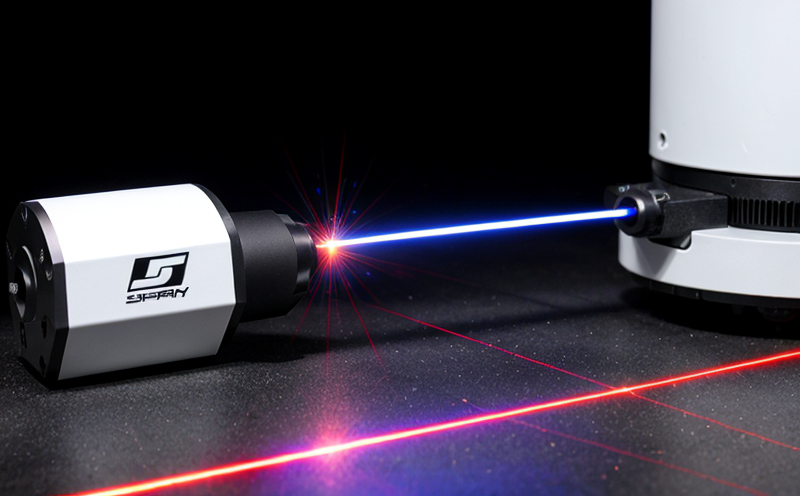

But what exactly is Laser Shearography, and how does it work? This advanced technology uses laser interferometry to measure minute changes in surface displacement caused by stress concentrations or defects. By analyzing these subtle variations, our technicians can identify even the smallest cracks that might be invisible to the naked eye.

Heres a step-by-step breakdown of the process

Preparation Our team prepares your material samples for inspection, ensuring they are free from contaminants and properly cleaned.

Data Acquisition Using high-precision lasers and interferometers, we generate detailed interference patterns that reflect surface displacements.

Image Processing Advanced algorithms analyze these patterns to identify stress concentrations and potential defects.

Quality Control Our experts verify results through rigorous quality control checks, ensuring the accuracy of our findings.

QA Your Most Pressing Questions Answered

We know you have questions about Laser Shearography for Surface Crack Detection. Here are some frequently asked questions that should give you a better understanding

Q What types of materials can be inspected using Laser Shearography?

A Our service is suitable for various materials, including metals (aluminum, steel, titanium), ceramics, composites, and more.

Q How does Laser Shearography compare to traditional NDT methods?

A This technique offers unparalleled sensitivity and accuracy compared to techniques like eddy current testing or radiography.

Q Can Laser Shearography detect subsurface defects?

A While it excels at surface crack detection, this technology can also identify some subsurface defects through advanced analysis of interference patterns.

Q How long does the inspection process typically take?

A Depending on sample size and complexity, inspections are completed in a matter of minutes or hours, not days.

Conclusion

In an industry where reliability, safety, and efficiency are paramount, Eurolabs Laser Shearography for Surface Crack Detection stands as a beacon of innovation. By harnessing the power of laser interferometry, our expert technicians can detect even the smallest surface cracks with unparalleled accuracy and speed.

Whether youre in the aerospace, automotive, or energy sectors, this cutting-edge technology is an indispensable tool that should be part of your quality control arsenal. Experience the benefits of Laser Shearography today trust Eurolab to unlock hidden defects and ensure the integrity of your materials.

Get Started with Eurolabs Laser Shearography Service

Contact our team to discuss how Laser Shearography can transform material inspection for your business. With expert analysis, rapid turnaround times, and unparalleled sensitivity, were committed to helping you stay ahead in a competitive market.