Long-cycle testing for robots used in precision tasks

The Pioneering Role of Long-Cycle Testing for Robots Used in Precision Tasks

In the era of Industry 0 and automation, robots have become an integral part of various industries, including manufacturing, healthcare, and aerospace. These precision instruments are designed to perform complex tasks with high accuracy and reliability. However, their performance can be compromised by factors such as wear and tear, software glitches, or human error. To ensure the optimal functioning of these robots, manufacturers and businesses rely on rigorous testing procedures. Among these tests, Long-cycle testing for robots used in precision tasks has emerged as a vital laboratory service that sets the standard for quality and reliability.

What is Long-Cycle Testing?

Long-cycle testing involves subjecting robots to prolonged periods of operation under controlled conditions to evaluate their performance over an extended period. This type of testing is specifically designed for robots used in precision tasks, where minute deviations can have significant consequences. At Eurolab, our team of experts employs cutting-edge technology and rigorous methodologies to conduct Long-cycle testing that simulates real-world scenarios. By doing so, we help businesses optimize their robotic systems, reduce downtime, and ensure compliance with industry standards.

Why is Long-Cycle Testing Crucial for Businesses?

In todays competitive landscape, businesses cannot afford to compromise on the performance of their robotic systems. Here are some compelling reasons why Long-cycle testing for robots used in precision tasks is essential

Improved Productivity By identifying and addressing potential issues early on, businesses can minimize downtime and maintain production levels, ultimately leading to increased productivity.

Enhanced Quality Long-cycle testing ensures that robots operate within specified tolerances, guaranteeing high-quality output and reducing the risk of defects or failures.

Cost Savings By preventing equipment failure and reducing maintenance requirements, businesses can save significant costs associated with repair, replacement, or downtime.

Compliance with Industry Standards Eurolabs Long-cycle testing meets or exceeds industry standards, ensuring that businesses remain compliant and avoid costly audits or recalls.

Competitive Advantage Companies that invest in Long-cycle testing demonstrate their commitment to quality and reliability, setting them apart from competitors and establishing a strong reputation in the market.

Key Benefits of Eurolabs Long-Cycle Testing Services

Here are some key benefits of our Long-cycle testing services

Customized Testing Programs Our team works closely with clients to develop tailored testing programs that meet specific requirements and industry standards.

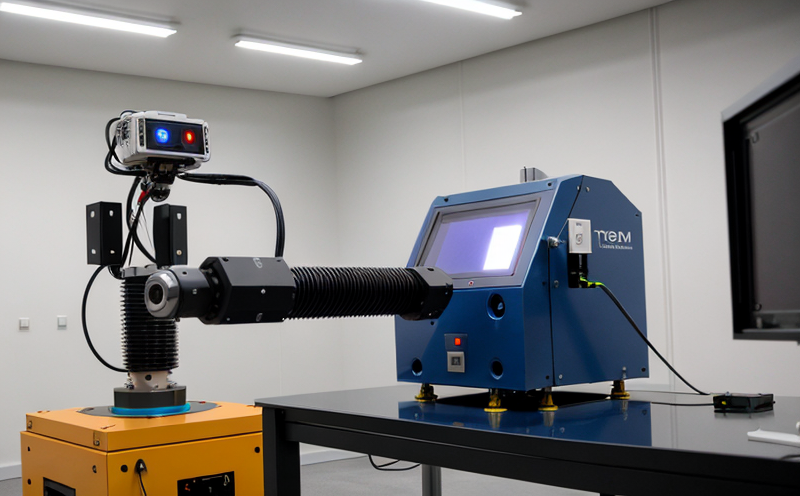

State-of-the-Art Facilities Eurolab operates in modern, well-equipped facilities that provide a controlled environment for Long-cycle testing.

Expert Analysis and Reporting Our experienced engineers and technicians analyze test results, providing detailed reports that help businesses identify areas for improvement.

Rapid Turnaround Times We strive to deliver timely results, enabling businesses to make informed decisions quickly and minimize downtime.

Frequently Asked Questions

Here are some common questions about Long-cycle testing for robots used in precision tasks

Q What types of robots can be tested using the Long-cycle testing procedure?

A Eurolabs Long-cycle testing services cater to a wide range of robotic systems, including industrial robots, collaborative robots (cobots), and humanoid robots.

Q How long does a typical Long-cycle test take?

A The duration of a Long-cycle test varies depending on the specific requirements and industry standards. Our team works closely with clients to determine the optimal testing timeframe.

Q What are the most common issues identified during Long-cycle testing?

A Common issues include wear and tear, software glitches, electrical malfunctions, and human error. However, our experts can identify and address other potential problems as well.

Conclusion

In conclusion, Eurolabs Long-cycle testing for robots used in precision tasks is a pioneering service that sets the standard for quality and reliability. By partnering with us, businesses can ensure the optimal performance of their robotic systems, reduce downtime, and stay ahead of industry standards. Dont compromise on the accuracy and precision of your robotic systems choose Eurolab for Long-cycle testing services that deliver results.

Why Choose Eurolab?

Our team at Eurolab is dedicated to delivering exceptional laboratory services tailored to meet specific business needs. We believe in

Collaboration Working closely with clients to understand their requirements and develop customized testing programs.

Innovation Leveraging cutting-edge technology and methodologies to ensure accuracy, efficiency, and reliability.

Expertise Employing experienced engineers and technicians who possess extensive knowledge of robotic systems and industry standards.

Get Started Today

Take the first step towards ensuring the optimal performance of your robotic systems. Contact Eurolab to discuss your specific testing requirements and schedule a consultation with our experts.