Long-term abrasion resistance testing for coatings

The Key to Durability Long-term Abrasion Resistance Testing for Coatings

In todays competitive market, businesses are constantly seeking ways to improve the performance and longevity of their products. For manufacturers who specialize in coating production, ensuring that these materials can withstand the rigors of daily use is crucial. This is where long-term abrasion resistance testing comes into play a laboratory service provided by Eurolab that simulates real-world conditions to determine the durability of your coatings.

What is Long-term Abrasion Resistance Testing?

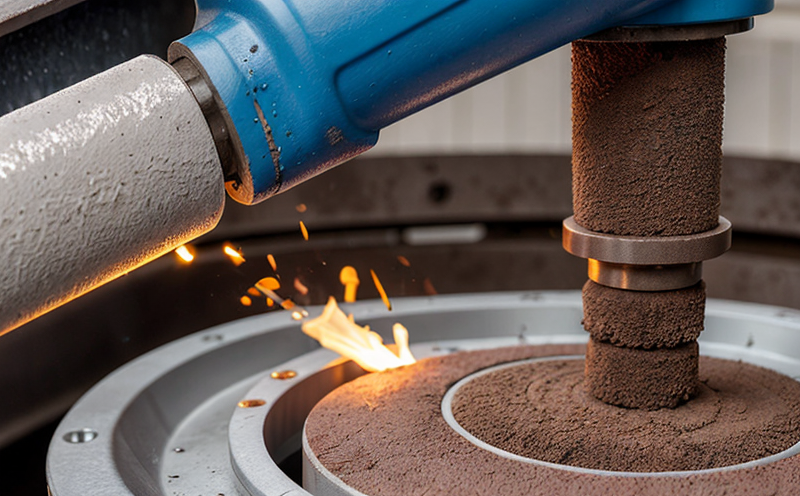

Long-term abrasion resistance testing, also known as accelerated wear testing or cyclic testing, is a scientific method used to evaluate how well a coating resists wear and tear over an extended period. This process involves repeatedly subjecting the coating to cycles of abrasive contact, such as rubbing or scratching, under controlled conditions to accelerate the wear process.

Why Long-term Abrasion Resistance Testing Matters

Incorporating long-term abrasion resistance testing into your quality control process can have a significant impact on your business. Here are just some of the advantages of using this laboratory service

Key Benefits

Reduced Product Failure By identifying areas where wear and tear is excessive, you can take corrective action to improve the formulation or application of your coatings, reducing the likelihood of product failure in the field.

Improved Customer Satisfaction Coatings that perform well under abrasion resistance testing are more likely to meet customer expectations, leading to increased satisfaction and loyalty.

Compliance with Industry Standards Many industries, such as aerospace, automotive, and construction, have specific regulations regarding the durability of coatings. Long-term abrasion resistance testing ensures your products comply with these standards.

Cost Savings By identifying potential issues early in the development process, you can avoid costly rework or recall efforts down the line.

Competitive Edge Demonstrating a commitment to durability and performance through long-term abrasion resistance testing can differentiate your company from competitors and give you a significant market advantage.

How Long-term Abrasion Resistance Testing Works

The process of long-term abrasion resistance testing involves several stages

Sample Preparation A representative sample of the coating is prepared for testing, typically in the form of a panel or strip.

Test Setup The test apparatus is set up to simulate the desired wear conditions, including factors such as temperature, humidity, and abrasive contact.

Cyclic Testing The coated sample is subjected to repeated cycles of abrasion, with each cycle consisting of a defined period of abrasion followed by a brief period of rest or recovery.

Data Collection Data on the wear rate, surface roughness, and other relevant parameters are collected at regular intervals throughout the test.

QA Long-term Abrasion Resistance Testing for Coatings

Q What types of coatings can be tested using long-term abrasion resistance testing?

A Eurolabs laboratory service is suitable for a wide range of coating types, including paint, powder coat, epoxy, polyurethane, and many others.

Q How does the test duration affect the results?

A The length of the test depends on the specific requirements of your project. Some tests may last only a few hours, while more extensive testing can be conducted over several days or even weeks.

Q What kind of data do I receive from long-term abrasion resistance testing?

A Eurolab provides detailed reports outlining the wear rate, surface roughness, and other relevant parameters at regular intervals throughout the test. This data allows you to assess the performance of your coatings under simulated real-world conditions.

Q Can long-term abrasion resistance testing be used for certification purposes?

A Yes, many industries require demonstration of a coatings durability through standardized testing protocols. Eurolab is equipped to provide testing that meets or exceeds industry standards for abrasion resistance.

Conclusion

Long-term abrasion resistance testing is an essential service for businesses involved in the production of coatings. By simulating real-world conditions and providing detailed data on wear performance, Eurolabs laboratory service can help you identify areas for improvement and ensure your products meet customer expectations.

Dont let product failure or non-compliance with industry standards hold you back. Choose Eurolab for long-term abrasion resistance testing and take the first step towards improved durability, reduced costs, and increased market share.