Measuring air movement through fabrics under varying pressure

Unlocking Optimal Air Permeability The Importance of Measuring Air Movement through Fabrics under Varying Pressure

In the world of textile manufacturing and product development, the ability to accurately measure air movement through fabrics under varying pressure is a crucial factor in determining the performance and quality of your products. Whether youre designing breathable athletic wear, creating thermal insulation for construction projects, or developing medical textiles with enhanced airflow properties, understanding the intricacies of air permeability is essential to ensuring that your final product meets stringent industry standards.

At Eurolab, we provide a comprehensive laboratory service tailored specifically to this need Measuring Air Movement through Fabrics under Varying Pressure. Our cutting-edge equipment and expert technicians enable us to deliver precise measurements, helping you refine your designs, optimize production processes, and ultimately improve the user experience of your products.

The Advantages of Measuring Air Movement through Fabrics under Varying Pressure

Our laboratory service offers a wide range of benefits that can significantly enhance the development and manufacturing process for textile-based products. Here are just a few key advantages

Improved Product Performance By understanding how air moves through fabrics under different pressures, you can optimize your designs to achieve better thermal regulation, moisture management, or flame retardancy all critical factors in various industries.

Enhanced User Experience With accurate measurements of air permeability, you can ensure that your products meet the comfort and performance expectations of end-users. Whether its athletic wear for high-intensity activities or medical textiles for sensitive patients, our service helps you create products that truly make a difference.

Reduced Material Waste By refining your production processes to achieve optimal air permeability, you can minimize material waste, lower costs, and reduce your environmental footprint all while maintaining the quality of your products.

Compliance with Industry Standards Our laboratory is equipped to test fabrics according to relevant industry standards (e.g., ASTM, ISO, or EN), ensuring that your products meet the stringent requirements of regulatory bodies.

Key Benefits at a Glance

Here are some key benefits of our Measuring Air Movement through Fabrics under Varying Pressure service

Customized Testing Programs We work closely with you to develop tailored testing programs that address specific product requirements and performance goals.

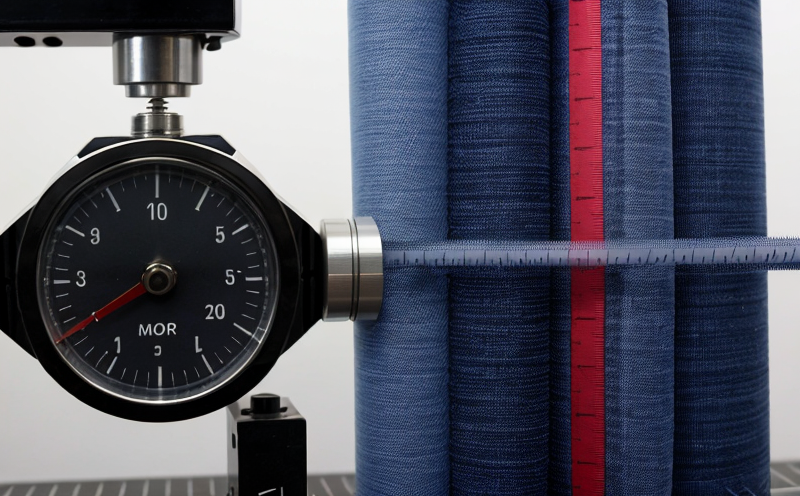

Accurate Measurement Techniques Our expert technicians use state-of-the-art equipment to provide precise measurements, eliminating the need for subjective assessments or manual calculations.

Comprehensive Reporting Detailed reports outlining test results, methodology, and recommendations enable informed decision-making throughout your development process.

Expert Consultation Our team of experienced professionals is available to guide you through the testing process, answer questions, and offer expert advice on interpreting results.

Frequently Asked Questions

What types of fabrics can be tested?

Our laboratory services are applicable to a wide range of textile materials, including natural fibers (cotton, wool), synthetic fibers (polyester, nylon), blends, and composite materials.

How do you measure air movement through fabrics under varying pressure?

We utilize specialized equipment, such as fabric permeameters or airflow meters, which simulate real-world conditions to accurately measure the airflow rate through samples of various thicknesses and densities.

What are the typical testing parameters used in Measuring Air Movement through Fabrics under Varying Pressure?

Typical parameters include airflow rate (m³/s), air pressure difference (Pa or kPa), sample thickness (mm or cm), and fabric density (g/m²).

Can you provide testing services for specific industries, such as medical textiles or outdoor gear?

Yes, our team has extensive experience working with various industries and can develop customized testing programs tailored to meet the unique requirements of your products.

How do I know which test method is suitable for my fabric type or product application?

Our experts will work closely with you to determine the most relevant test methods based on your specific needs, ensuring that our service meets your project objectives.

Conclusion

Measuring air movement through fabrics under varying pressure is an essential component of textile development and manufacturing. By partnering with Eurolab, you can unlock optimal air permeability in your products, resulting in improved performance, user experience, and compliance with industry standards. Our expert technicians, cutting-edge equipment, and comprehensive reporting ensure that our service delivers precise measurements tailored to meet the specific needs of your business.

Dont compromise on product quality or performance choose Eurolab for Measuring Air Movement through Fabrics under Varying Pressure and discover the difference that accurate measurement can make in your industry.