Measuring coating hardness after accelerated aging

Measuring Coating Hardness after Accelerated Aging Unlocking the Secrets to Your Coatings Durability

In todays fast-paced industrial landscape, materials and coatings play a critical role in ensuring the performance, efficiency, and longevity of products and equipment. Among these, coating hardness is an essential parameter that dictates how well your coatings can withstand various environmental conditions, including temperature fluctuations, chemical exposure, and physical stress. However, determining coating hardness after accelerated aging poses significant challenges for businesses. This is where Eurolabs expert laboratory service steps in Measuring Coating Hardness after Accelerated Aging.

What is Measuring Coating Hardness after Accelerated Aging?

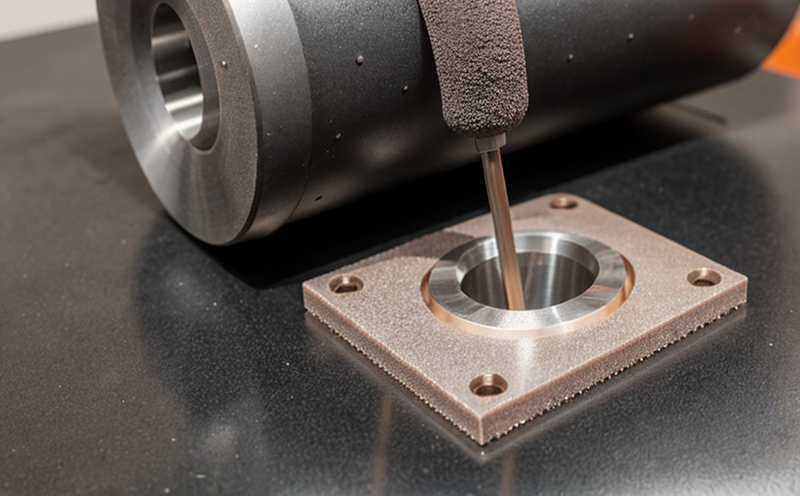

Measuring Coating Hardness after Accelerated Aging is a specialized laboratory service that involves simulating the effects of environmental stress on coatings to evaluate their hardness and durability. This accelerated aging process replicates various conditions such as exposure to heat, cold, chemicals, or UV light to accelerate degradation processes. By doing so, it becomes possible to assess how well your coating will perform under real-world scenarios.

Why is Measuring Coating Hardness after Accelerated Aging Essential for Your Business?

In todays competitive market, manufacturers face increasingly stringent performance and durability requirements from customers. As such, being able to accurately predict the lifespan of coatings is vital for making informed product development decisions. Here are some compelling reasons why Measuring Coating Hardness after Accelerated Aging is a game-changer for your business

Key Advantages of Using Eurolabs Measuring Coating Hardness after Accelerated Aging Service

Improved Product Reliability By evaluating coating hardness under accelerated aging conditions, you can identify potential weaknesses and modify formulations to ensure your coatings meet performance expectations.

Enhanced Durability Understanding how well your coatings withstand environmental stressors allows for targeted improvements in durability and lifespan, reducing the need for frequent replacements or repairs.

Increased Efficiency With a reliable and accurate measure of coating hardness after accelerated aging, you can streamline production processes and optimize resource allocation, minimizing costs associated with rework or scrap materials.

Competitive Advantage By leveraging Eurolabs expertise in Measuring Coating Hardness after Accelerated Aging, you can differentiate your products from competitors, enhancing market reputation and customer satisfaction.

Compliance and Regulatory Requirements Adhering to industry standards for coating durability is crucial. Our service ensures that your coatings meet or exceed regulatory requirements, reducing the risk of costly recalls or fines.

Benefits for Various Industries

Aerospace and Defense High-performance coatings must withstand extreme temperatures and environmental conditions. Measuring Coating Hardness after Accelerated Aging helps ensure these coatings are capable of meeting demanding specifications.

Automotive The durability of coatings in automotive applications can significantly impact vehicle performance, safety, and lifespan. Our service ensures your coatings meet the rigorous standards required by this industry.

Electronics Electronic components often require specialized coatings to protect against corrosion and environmental stressors. By evaluating coating hardness under accelerated aging conditions, we help manufacturers optimize these coatings for improved performance.

Real-World Applications

Paints and Coatings Industry Manufacturers of paints and coatings can utilize Measuring Coating Hardness after Accelerated Aging to develop more durable products that meet customer expectations.

Automotive Industry Car manufacturers use this service to evaluate the durability of coatings on automotive components, ensuring they withstand environmental conditions.

Aerospace and Defense Industry The development of high-performance coatings for aerospace applications is critical for maintaining aircraft safety and performance.

QA Section

Q What types of materials can be evaluated using Measuring Coating Hardness after Accelerated Aging?

A A wide range of coatings, including paints, enamels, epoxies, polyurethanes, and other materials, can be assessed for their hardness under accelerated aging conditions.

Q How long does the accelerated aging process take?

A The duration of the accelerated aging process varies depending on the specific testing protocol used. However, our state-of-the-art facilities enable us to conduct these tests efficiently while maintaining high accuracy.

Q What kind of data can I expect from this service?

A Our comprehensive report provides detailed information about your coatings hardness and durability under various environmental conditions. This includes a thorough analysis of the test results, recommendations for improvement, and suggested modifications for enhanced performance.

Conclusion

In an ever-evolving industrial landscape where performance and efficiency are paramount, understanding how well coatings withstand environmental stressors is no longer a luxury but a necessity. Eurolabs Measuring Coating Hardness after Accelerated Aging service offers the cutting-edge technology and expertise to ensure your coatings meet or exceed industry standards.

Whether youre looking to improve product reliability, enhance durability, increase efficiency, gain a competitive advantage, or simply comply with regulatory requirements, our laboratory service is here to help. By partnering with Eurolab, you can unlock the secrets to your coatings performance, paving the way for innovative solutions that drive growth and success in todays fast-paced markets.

Dont just meet standards exceed them. Trust Eurolab for Measuring Coating Hardness after Accelerated Aging and take a significant step towards creating products that truly stand out in their class.