Measuring flexibility in coatings for industrial applications

The Importance of Measuring Flexibility in Coatings for Industrial Applications

As the demand for high-performance coatings continues to grow, manufacturers are under increasing pressure to ensure that their products meet the rigorous standards required for industrial applications. One critical aspect of coating development and quality control is measuring flexibility a crucial parameter that can make or break a coatings performance in harsh environments.

Measuring flexibility in coatings for industrial applications is a specialized laboratory service offered by Eurolab, a trusted leader in materials testing and analysis. Our state-of-the-art facilities and expert team enable us to provide accurate and reliable results, helping businesses like yours to overcome the challenges associated with coating development and ensure their products meet the highest standards of quality.

Why Measuring Flexibility is Essential for Industrial Applications

In industrial settings, coatings are exposed to a wide range of stresses, including temperature fluctuations, humidity changes, and mechanical impacts. If a coating lacks flexibility, it may crack or fail under these conditions, leading to reduced product lifespan, increased maintenance costs, and even catastrophic failures.

The consequences of inadequate coating flexibility can be severe

Reduced product performance and efficiency

Increased risk of contamination and spoilage

Higher maintenance and repair costs

Loss of customer trust and reputation

On the other hand, coatings that exhibit excellent flexibility are better equipped to withstand the rigors of industrial environments. This can lead to significant benefits, including

Advantages of Measuring Flexibility in Coatings for Industrial Applications

Our measuring flexibility services offer a range of advantages that can help businesses like yours achieve their goals.

Improved Product Performance By understanding a coatings flexibility, manufacturers can develop products that meet specific performance requirements, ensuring optimal results in various industrial settings.

Enhanced Durability Flexible coatings are less prone to cracking and failure, resulting in longer product lifespan and reduced maintenance costs.

Increased Efficiency Coatings with excellent flexibility can withstand temperature fluctuations, humidity changes, and mechanical impacts, reducing the need for costly repairs or replacements.

Better Quality Control Measuring flexibility enables manufacturers to identify potential issues early on, ensuring that products meet quality standards and regulatory requirements.

Key Benefits of Our Measuring Flexibility Services

Accurate Results Our state-of-the-art equipment and expert team provide precise measurements, enabling businesses to make informed decisions about coating development and quality control.

Customized Solutions We offer tailored testing services to meet the specific needs of each client, including customized testing protocols and data analysis.

Cost-Effective By identifying potential issues early on, manufacturers can avoid costly rework or repairs, reducing overall production costs.

Compliance with Regulations Our measuring flexibility services help ensure that coatings comply with industry standards and regulatory requirements.

Frequently Asked Questions (FAQs)

At Eurolab, we understand the importance of clear communication and transparency. Below are some frequently asked questions about our Measuring Flexibility in Coatings for Industrial Applications service

Q What is measuring flexibility?

A Measuring flexibility involves testing a coatings ability to deform under stress without cracking or failing.

Q Why is measuring flexibility important for industrial applications?

A Flexible coatings are better equipped to withstand the rigors of industrial environments, ensuring optimal performance and reducing maintenance costs.

Q How do you measure flexibility?

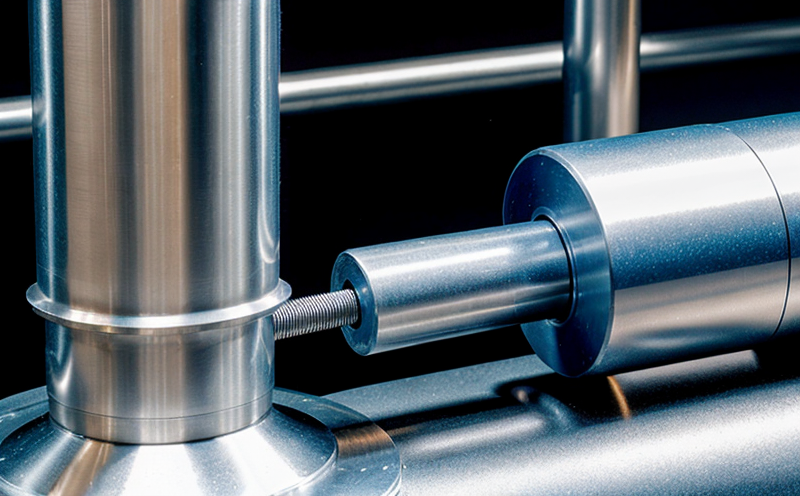

A We use state-of-the-art equipment, including tensile testing machines, flexural testers, and other specialized instruments to accurately measure a coatings flexibility.

Q What types of coatings can be tested for flexibility?

A Our services cover a wide range of coatings, including paints, varnishes, epoxies, polyurethanes, and more.

Q Can you provide customized testing protocols and data analysis?

A Yes, our team is experienced in developing tailored testing protocols to meet the specific needs of each client, along with comprehensive data analysis and reporting.

Conclusion

Measuring flexibility in coatings for industrial applications is a critical aspect of coating development and quality control. By understanding a coatings ability to deform under stress without cracking or failing, manufacturers can develop products that meet specific performance requirements, ensuring optimal results in various industrial settings.

At Eurolab, we offer a comprehensive Measuring Flexibility in Coatings for Industrial Applications service, providing accurate and reliable results that help businesses achieve their goals. Our team is dedicated to delivering high-quality services, tailored to the unique needs of each client.

Dont let inadequate coating flexibility compromise your products performance or reputation. Contact Eurolab today to learn more about our Measuring Flexibility in Coatings for Industrial Applications service and take the first step towards developing coatings that meet the highest standards of quality and performance.