Measuring Overvoltage Sensitivity in Industrial Control Systems

Unlocking Efficient Industrial Operations Measuring Overvoltage Sensitivity in Industrial Control Systems

In todays fast-paced industrial landscape, ensuring the reliability and efficiency of control systems is paramount to maintaining productivity and minimizing downtime. One crucial aspect that often goes unnoticed yet has a significant impact on system performance is overvoltage sensitivity. This phenomenon can lead to equipment damage, data loss, and even safety hazards if left unaddressed. At Eurolab, we offer a comprehensive laboratory service designed to measure the overvoltage sensitivity of industrial control systems, empowering businesses to optimize their operations and mitigate potential risks.

What is Measuring Overvoltage Sensitivity in Industrial Control Systems?

Overvoltage sensitivity refers to the susceptibility of electronic devices or systems to voltage spikes or surges that can cause damage or malfunction. In industrial settings, this issue is particularly concerning due to the high-stakes nature of equipment and processes involved. When an overvoltage event occurs, it can lead to a range of problems, from minor malfunctions to catastrophic failures. Measuring the overvoltage sensitivity of control systems involves simulating voltage surges in a laboratory setting to determine the systems tolerance levels and identify potential vulnerabilities.

Why is Measuring Overvoltage Sensitivity in Industrial Control Systems Essential?

Incorporating overvoltage sensitivity measurement into your quality assurance routine can have numerous benefits, including

Key Benefits of Measuring Overvoltage Sensitivity

Prevents Equipment Failure By identifying vulnerable components and adjusting system settings accordingly, businesses can prevent costly equipment failures and minimize downtime.

Ensures Data Integrity Measuring overvoltage sensitivity helps safeguard against data loss due to power surges or voltage fluctuations that could compromise sensitive information.

Optimizes System Performance Regular testing enables companies to fine-tune their systems for optimal performance, reducing the risk of malfunctions and ensuring reliable operation.

Compliance with Industry Standards Many regulatory bodies require regular inspection and maintenance of industrial control systems to ensure they meet specified safety standards. Measuring overvoltage sensitivity is an essential part of this process.

Reduces Maintenance Costs By proactively addressing potential issues, businesses can lower their long-term maintenance costs associated with repairs and replacements.

Enhances Safety Identifying and mitigating the risks posed by overvoltage events contributes to a safer working environment for personnel and protects against costly lawsuits.

The Importance of Accuracy in Measuring Overvoltage Sensitivity

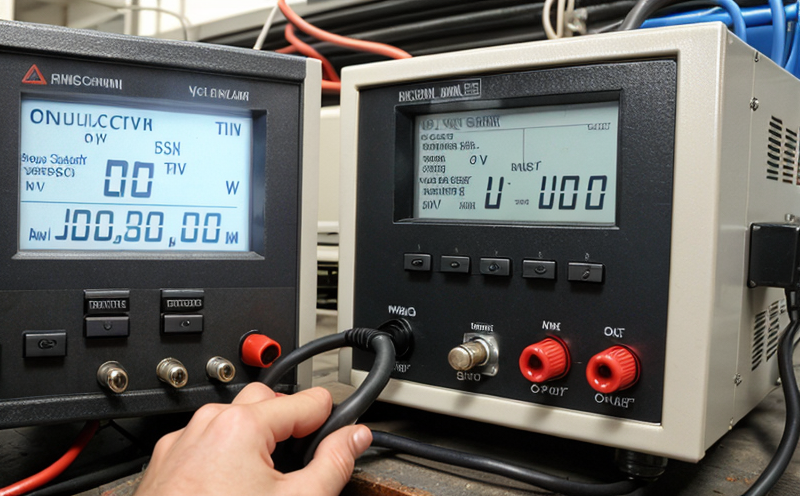

Accurate measurement is crucial when assessing an industrial control systems sensitivity to voltage surges. Inaccurate results can lead to false assumptions about system performance, which may result in inadequate mitigation strategies or unnecessary upgrades. To ensure reliable data, Eurolab employs state-of-the-art testing equipment and methodologies that simulate real-world scenarios with precision.

Common Misconceptions About Measuring Overvoltage Sensitivity

QA Section

Q What is the purpose of measuring overvoltage sensitivity in industrial control systems?

A The primary goal is to identify potential vulnerabilities to voltage surges or spikes, which can lead to equipment damage, data loss, and safety hazards if left unaddressed.

Q How does Eurolabs laboratory service measure overvoltage sensitivity?

A Our expert technicians utilize specialized testing equipment that simulates various voltage surge scenarios to determine the systems tolerance levels and identify areas for improvement.

Q Why is it essential to regularly test industrial control systems for overvoltage sensitivity?

A Regular testing ensures that your systems are operating at peak performance, reducing downtime and minimizing risks associated with equipment failure or data loss.

Q What benefits can I expect from measuring overvoltage sensitivity in my industrial control system?

A By doing so, youll enjoy enhanced system reliability, reduced maintenance costs, compliance with industry standards, and improved workplace safety.

Choosing the Right Partner for Measuring Overvoltage Sensitivity

When selecting a laboratory service provider to measure the overvoltage sensitivity of your industrial control systems, look for expertise in this specialized field. Eurolabs team is dedicated to delivering high-quality results that meet or exceed industry standards. Our commitment to precision and customer satisfaction ensures that you receive actionable insights to optimize your operations.

Conclusion

Measuring overvoltage sensitivity in industrial control systems is a critical step towards optimizing efficiency, ensuring data integrity, and preventing equipment failure. By investing in this laboratory service from Eurolab, businesses can mitigate potential risks associated with voltage surges or spikes, contributing to improved system performance, reduced downtime, and enhanced workplace safety.

At Eurolab, were committed to supporting your industrial operations by providing accurate, reliable, and actionable results that empower informed decision-making. Trust our team of experts to measure the overvoltage sensitivity of your control systems and unlock more efficient, productive, and resilient industrial processes.