Methods for dimensional accuracy testing of medical devices

Ensuring Precision in Medical Devices Why Dimensional Accuracy Testing Matters

In the world of medical devices, precision is paramount. The accuracy and reliability of these devices can mean the difference between life and death, making it essential for manufacturers to ensure that their products meet the highest standards of dimensional accuracy. At Eurolab, our laboratory service provides a comprehensive solution for businesses seeking to verify the dimensional accuracy of their medical devices. In this article, we will delve into the importance of dimensional accuracy testing, its benefits, and the methods employed by Eurolab to provide accurate results.

What is Dimensional Accuracy Testing?

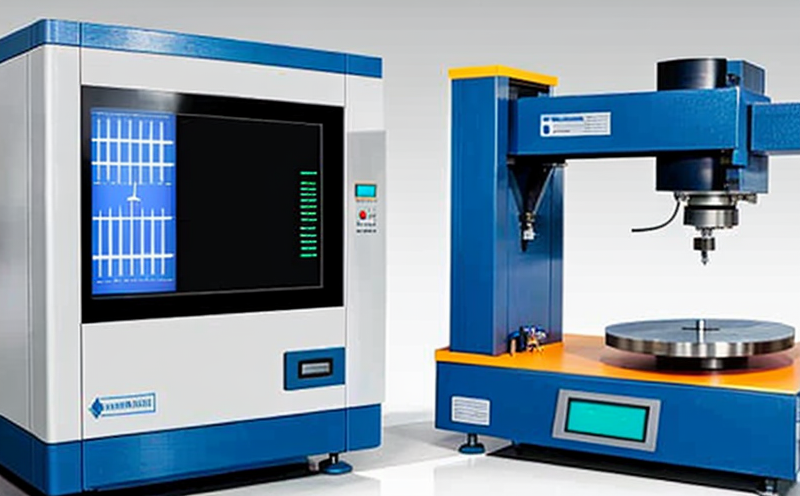

Dimensional accuracy testing, also known as measurement validation or calibration, involves verifying that a medical devices dimensions are within predetermined tolerances. This process ensures that the device functions as intended, meets regulatory requirements, and provides reliable performance in real-world applications. At Eurolab, our experienced team uses state-of-the-art equipment to measure the dimensions of your medical devices with unparalleled precision.

Why is Dimensional Accuracy Testing Essential for Businesses?

Compliance with Regulatory Requirements Medical devices must adhere to strict regulatory guidelines, including those related to dimensional accuracy. Non-compliance can result in costly fines, product recalls, and damage to a companys reputation.

Product Reliability and Performance Accurate dimensions ensure that medical devices function as intended, reducing the risk of malfunction or failure.

Patient Safety Medical devices must be designed with patient safety in mind. Dimensional accuracy testing helps prevent adverse events associated with inaccurate device performance.

Increased Efficiency and Cost Savings By identifying dimensional inaccuracies early on, manufacturers can avoid costly rework, reduce waste, and improve overall production efficiency.

Enhanced Brand Reputation Companies that prioritize dimensional accuracy testing demonstrate a commitment to quality and reliability, which can lead to increased customer trust and loyalty.

Benefits of Using Eurolabs Dimensional Accuracy Testing Services

Expertise and Experience Our team has extensive knowledge and experience in dimensional accuracy testing for medical devices.

State-of-the-Art Equipment We utilize the latest measurement technologies to ensure accurate and reliable results.

Customized Solutions Our services are tailored to meet the specific needs of each client, ensuring that your medical devices receive the attention they require.

Rapid Turnaround Times We understand the importance of timely testing and provide fast turnaround times without compromising on accuracy.

Compliance with Regulatory Standards Our testing methods adhere to international standards, including ISO 17025, ensuring compliance with regulatory requirements.

Methods for Dimensional Accuracy Testing at Eurolab

Our laboratory service employs a range of methods to test the dimensional accuracy of medical devices. These include

Calibration and Measurement We use precision instruments to measure the dimensions of your medical devices.

Dimensional Analysis Our team analyzes data from measurements to identify any deviations from predetermined tolerances.

Validation and Verification We validate our testing methods against industry standards, ensuring that our results are accurate and reliable.

Frequently Asked Questions

Q What types of medical devices can be tested for dimensional accuracy?

A Eurolab provides dimensional accuracy testing services for a wide range of medical devices, including implants, surgical instruments, and diagnostic equipment.

Q How do I prepare my medical devices for testing?

A Please provide your devices as received from the manufacturer or supplier, along with any relevant documentation or specifications.

Q What are the turnaround times for dimensional accuracy testing at Eurolab?

A Our standard turnaround time is insert timeframe, but we can accommodate urgent requests when necessary.

Q Are your testing methods compliant with international standards?

A Yes, our laboratory service adheres to ISO 17025 and other relevant industry standards.

Conclusion

Dimensional accuracy testing is a crucial step in ensuring the reliability and performance of medical devices. At Eurolab, we provide a comprehensive solution for businesses seeking to verify the dimensional accuracy of their products. Our team employs state-of-the-art equipment and methods to deliver accurate results quickly and efficiently. By choosing Eurolabs laboratory service, you can trust that your medical devices meet the highest standards of precision and reliability.

Get in Touch with Us

Contact us today to learn more about our dimensional accuracy testing services for medical devices. Our team is ready to help you ensure the quality and performance of your products.