The Importance of Molded Shape Retention Ensuring Quality and Consistency in Your Materials

In todays competitive business landscape, ensuring the quality and consistency of your materials is crucial for maintaining customer satisfaction, reducing waste, and minimizing costs. One laboratory service that plays a vital role in achieving these goals is Molded shape retention testing. Provided by Eurolab, this comprehensive testing solution allows businesses to verify the accuracy and stability of their molded products dimensions over time.

What is Molded Shape Retention?

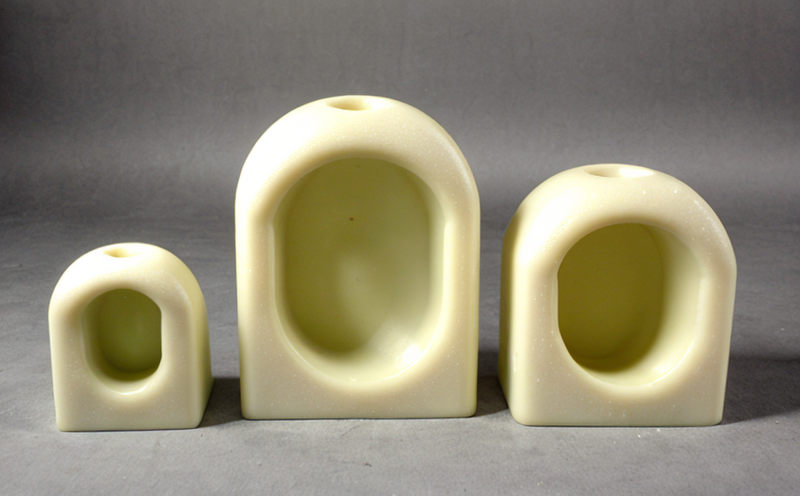

Molded shape retention refers to the ability of a material to maintain its shape and dimensional integrity after being molded or formed into a specific configuration. This property is essential for ensuring that your products meet industry standards, perform as intended, and exhibit consistent behavior in various environments. By evaluating the moldability and retaining properties of a material, Eurolab helps businesses make informed decisions about their product development and production processes.

Why Choose Molded Shape Retention Testing?

The benefits of incorporating Molded shape retention testing into your quality control process are numerous

Improved Quality Control Ensure that your products meet the required specifications and dimensions by verifying their molded shape retention.

Reduced Waste and Costs Minimize waste generation and reduce costs associated with reworking or scrapping defective products.

Enhanced Customer Satisfaction Meet customer expectations by delivering high-quality products that perform consistently over time.

Increased Efficiency Streamline your production process by identifying material properties that affect moldability and shape retention.

Key Benefits of Molded Shape Retention Testing

Here are some key benefits of incorporating Molded shape retention testing into your business

Comprehensive Analysis Eurolabs experts conduct a thorough evaluation of your materials molded shape retention, providing you with a detailed report of their performance.

Customized Solutions Our team works closely with you to develop tailored testing programs that address your specific needs and industry requirements.

State-of-the-Art Facilities Our laboratory is equipped with cutting-edge equipment and technologies, ensuring accurate and reliable test results.

Expert Support Our experienced staff provides expert guidance throughout the testing process, helping you navigate complex material properties and industry standards.

Frequently Asked Questions

Here are some common questions about Molded shape retention testing

What types of materials can be tested for molded shape retention?

Plastics

Elastomers

Thermosets

Composites

How does Eurolabs testing process work?

Our team receives your samples and conducts a thorough analysis, including test planning, sample preparation, and data interpretation.

What are the advantages of using Molded shape retention testing for my business?

Improved quality control, reduced waste and costs, enhanced customer satisfaction, and increased efficiency.

Conclusion

In todays competitive market, it is essential to ensure that your products meet industry standards and exhibit consistent behavior over time. Eurolabs Molded shape retention testing service provides a comprehensive solution for verifying the accuracy and stability of your materials dimensions. By choosing this laboratory service, businesses can improve quality control, reduce waste and costs, enhance customer satisfaction, and increase efficiency. Contact us today to learn more about how Molded shape retention testing can benefit your business.