Monitoring the effects of abuse on battery systems with multiple cells or modules

Unlocking the Secrets of Battery System Reliability Understanding the Impact of Abuse on Multi-Cell/Module Systems

As the world becomes increasingly reliant on battery-powered technologies, ensuring the reliability and longevity of these systems has never been more crucial. The use of multiple cells or modules in a single system is becoming increasingly common, but it also introduces new challenges. Battery systems with multiple cells or modules are more complex than their single-cell counterparts, making them more susceptible to various forms of abuse. This can lead to decreased performance, reduced lifespan, and even catastrophic failures.

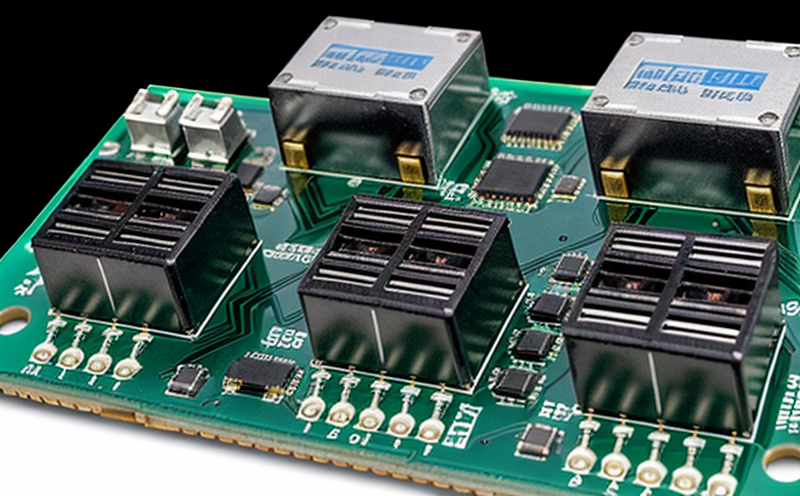

At Eurolab, our team of expert engineers understands the importance of monitoring the effects of abuse on battery systems with multiple cells or modules. Our laboratory service is specifically designed to help businesses like yours understand the behavior of their complex battery systems under various stress conditions. By using our state-of-the-art testing equipment and expertise, you can gain valuable insights into the performance and reliability of your battery system.

What is Monitoring the Effects of Abuse on Battery Systems with Multiple Cells or Modules?

Monitoring the effects of abuse on battery systems with multiple cells or modules involves subjecting a battery system to various forms of stress, such as overcharging, over-discharging, high-temperature exposure, and vibration. Our team of engineers uses sophisticated equipment to simulate these conditions in a controlled laboratory environment.

By replicating real-world scenarios, we can identify potential weaknesses and vulnerabilities within the system. This allows us to provide you with actionable recommendations on how to improve the design, optimize performance, and ensure the long-term reliability of your battery system.

Why is it Essential for Businesses?

In todays competitive market, businesses cannot afford to compromise on product quality or reliability. A single failure can lead to lost revenue, damaged reputation, and regulatory non-compliance. By monitoring the effects of abuse on battery systems with multiple cells or modules, you can

Ensure Compliance Our testing services help ensure that your products meet industry standards and regulations.

Improve Performance By identifying potential weaknesses, we can provide recommendations to optimize performance and extend lifespan.

Reduce Costs By minimizing failures and extending lifespan, our testing services can help reduce costs associated with product replacement and maintenance.

Enhance Customer Satisfaction Our expertise helps ensure that your products meet customer expectations, leading to increased satisfaction and loyalty.

Key Benefits of Using Monitoring the Effects of Abuse on Battery Systems with Multiple Cells or Modules

Early Detection of Potential Issues Our testing services help identify potential weaknesses before they become major problems.

Optimized Design and Performance By understanding how your system behaves under stress conditions, we can provide recommendations for improvement.

Increased Safety Our testing helps ensure that your products meet industry standards and regulatory requirements.

Cost Savings By minimizing failures and extending lifespan, our services can help reduce costs associated with product replacement and maintenance.

Enhanced Competitiveness Our expertise helps ensure that your products meet customer expectations, leading to increased market share and competitiveness.

A Comprehensive QA Section

Q What types of abuse testing do you offer?

A We offer a range of testing services, including overcharging, over-discharging, high-temperature exposure, vibration, and more.

Q Why is it necessary to test battery systems with multiple cells or modules in a controlled laboratory environment?

A Testing in a controlled lab environment allows us to replicate real-world scenarios and identify potential weaknesses that may not be apparent through other testing methods.

Q How long does the testing process typically take?

A The duration of our testing services varies depending on the specific requirements of your project. We work closely with clients to ensure that testing is completed efficiently while maintaining high-quality results.

Q What kind of expertise do your engineers bring to the table?

A Our team consists of experienced engineers who specialize in battery systems and electrical engineering. They have a deep understanding of complex battery system behavior under various stress conditions.

Q Can you provide recommendations for improving design and performance based on our testing results?

A Absolutely! Our expert engineers use their knowledge and experience to provide actionable recommendations tailored to your specific needs.

Conclusion

Monitoring the effects of abuse on battery systems with multiple cells or modules is a critical step in ensuring the reliability and longevity of these complex systems. At Eurolab, we offer a comprehensive laboratory service designed to help businesses like yours understand the behavior of their battery systems under various stress conditions. By partnering with us, you can gain valuable insights into your systems performance and make informed decisions about design improvements.

Dont let potential weaknesses compromise your products reliability or lifespan. Contact Eurolab today to learn more about our state-of-the-art testing services and how we can help you unlock the full potential of your battery systems.

About Eurolab

Eurolab is a leading provider of laboratory testing services for complex battery systems. Our team of expert engineers has extensive experience in designing, developing, and testing advanced battery technologies. With state-of-the-art equipment and facilities, we offer a range of testing services to help businesses optimize performance, ensure compliance, and reduce costs associated with product development.

Related Services

In addition to monitoring the effects of abuse on battery systems with multiple cells or modules, Eurolab offers a range of related services, including

Battery Testing Our team provides comprehensive testing and evaluation of battery performance under various stress conditions.

Cell and Module Design Optimization Our engineers can help optimize cell and module design for improved performance and reliability.

System Integration and Validation We offer system integration and validation services to ensure seamless interaction between battery systems and other components.

By partnering with Eurolab, you can leverage our expertise to overcome complex battery system challenges and bring innovative products to market faster.

-

Simulating extreme abuse conditions to assess battery safety

-

Testing for the impact of physical abuse (e.g., crushing, piercing) on battery cells

-

Evaluating battery performance under overcharge, short circuit, and thermal abuse

-

Simulating high-temperature exposure, punctures, and shocks to test battery limits

-

Assessing the risk of thermal runaway or fire under abusive conditions

-

Measuring gas venting, leakage, and potential explosion during abuse testing

-

Abuse testing for batteries used in electric vehicles and energy storage systems

-

Determining the resilience of battery protection circuits under abuse conditions

-

Testing for failure modes and internal damage under extreme stress conditions

-

Evaluating the impact of abusive handling on battery lifespan

-

Assessing the environmental impact of abuse testing for battery disposal

-

Testing batteries under abusive conditions for use in military applications

-

Simulating physical and environmental abuse scenarios for high-power batteries

-

Determining the impact of external abuse on battery voltage, capacity, and efficiency

-

Abuse testing for batteries used in consumer electronics and power tools

-

Testing the effectiveness of safety mechanisms in preventing battery failure

-

Assessing performance degradation due to abuse over time

-

Abuse testing for batteries used in renewable energy and backup power systems

-

Testing for safety compliance with industry standards for battery abuse resistance