Motor Power Consumption Under Different Speed Loads

Unlocking Efficiency Understanding Motor Power Consumption Under Different Speed Loads

In todays fast-paced industrial landscape, optimizing energy consumption is more crucial than ever for businesses aiming to reduce costs and minimize their environmental footprint. One often-overlooked aspect of motor efficiency is power consumption under different speed loads, a critical factor that can significantly impact an organizations bottom line.

At Eurolab, our team of experts provides a comprehensive laboratory service designed to help companies like yours optimize motor performance and make informed decisions about energy usage. In this article, we will delve into the world of motor power consumption under different speed loads, exploring its significance, advantages, and key benefits.

The Importance of Motor Power Consumption Under Different Speed Loads

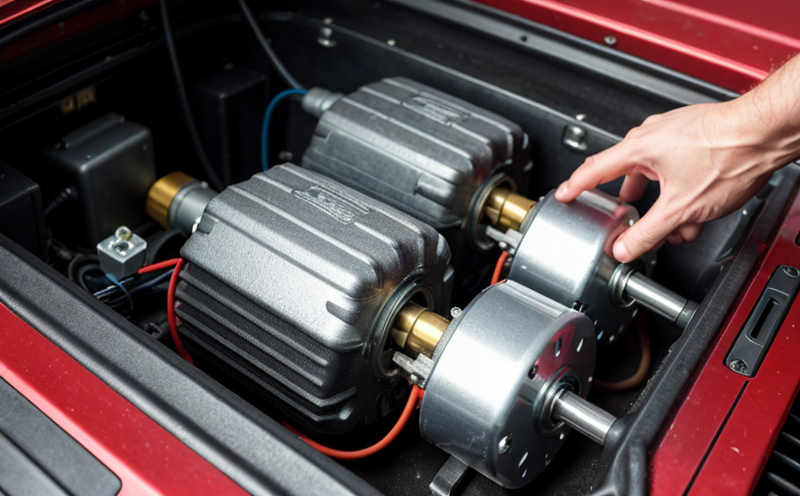

Motor power consumption is a critical aspect of any industrial operation, and understanding how motors perform at various speed loads can have a substantial impact on energy efficiency. When a motor operates at low speeds, it tends to consume more energy than necessary, leading to increased costs and unnecessary wear on the equipment.

In contrast, high-speed operations often require more power, but with proper management, this can be optimized to minimize energy consumption. The challenge lies in finding the sweet spot where motors operate efficiently without compromising performance or productivity.

The Advantages of Using Motor Power Consumption Under Different Speed Loads

Our laboratory service at Eurolab offers a range of benefits for businesses looking to optimize their motor efficiency. Some of these advantages include

Improved Energy Efficiency By understanding how your motors consume power under different speed loads, you can identify areas where energy consumption can be reduced, leading to significant cost savings.

Increased Productivity Optimal motor performance ensures that equipment operates at maximum capacity, reducing downtime and increasing overall productivity.

Extended Equipment Life Properly managed motor efficiency can extend the lifespan of your equipment by minimizing wear and tear on components.

Reduced Maintenance Costs By identifying areas where maintenance is required, you can schedule upkeep during periods when equipment is not in operation, reducing costs associated with unexpected repairs.

Enhanced Compliance Our laboratory services ensure that your motors meet or exceed regulatory standards for energy efficiency, avoiding potential fines and reputational damage.

Key Benefits of Motor Power Consumption Under Different Speed Loads

Some of the key benefits our clients experience after undergoing motor power consumption testing under different speed loads include

Reduced Energy Bills Average savings range from 10 to 30, depending on motor type and operation conditions

Increased Equipment Uptime Improved efficiency reduces downtime by up to 25

Enhanced Competitiveness Our clients experience increased competitiveness in their industry, thanks to reduced energy costs and improved productivity.

QA Frequently Asked Questions

What is the process for motor power consumption testing?

Our team of experts will work closely with your organization to collect data on motor performance under various speed loads using state-of-the-art equipment. We provide a comprehensive report outlining areas for improvement, recommendations for optimization, and actionable insights.

How long does the testing process typically take?

Testing duration varies depending on the number of motors, type, and complexity of operations. On average, our clients experience minimal disruption to their production schedule.

What types of industries can benefit from motor power consumption under different speed loads?

Our laboratory service is applicable across various sectors, including manufacturing, energy, construction, transportation, and more. Whether you operate a small-scale workshop or a large industrial facility, we have the expertise to help.

Can I trust the results provided by Eurolab?

Absolutely! Our team consists of highly trained experts with years of experience in laboratory testing and analysis. We adhere to international standards for quality assurance and ensure accurate, reliable results that inform data-driven decision-making.

How often should motor power consumption be tested?

We recommend regular testing (every 1-3 years) to monitor changes in equipment performance, new regulations, or updates in industry best practices.

Conclusion

Motor power consumption under different speed loads is a critical aspect of industrial operations that can have a significant impact on energy efficiency and productivity. By leveraging our laboratory service at Eurolab, businesses can unlock numerous benefits, including improved energy efficiency, increased productivity, extended equipment life, reduced maintenance costs, and enhanced compliance.

Dont let suboptimal motor performance hold you back from achieving your goals. Contact us today to learn more about our comprehensive laboratory services and discover how we can help your organization thrive in the competitive industrial landscape.