Noise and Vibration Testing of Brake Components

Unlocking Quiet Performance The Importance of Noise and Vibration Testing of Brake Components

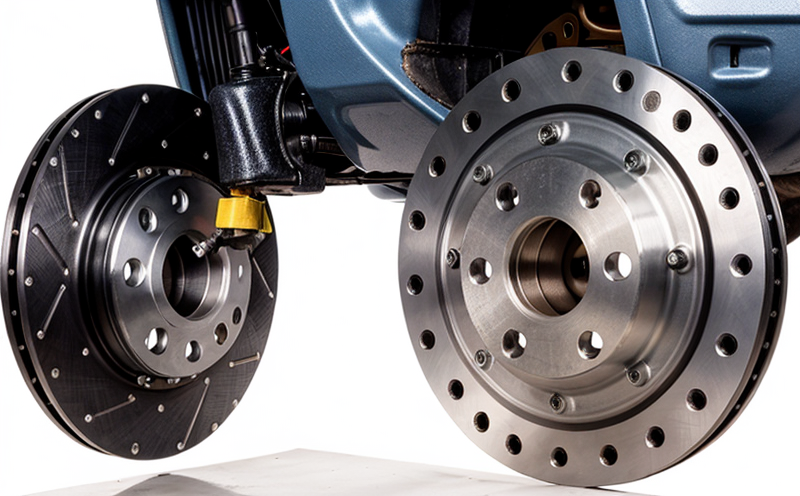

In the world of automotive engineering, brake components play a vital role in ensuring the safety and performance of vehicles on the road. However, brake noise and vibration can significantly impact a vehicles overall driving experience, compromising its reliability and even putting drivers at risk. Thats where Eurolab comes in as a leading provider of laboratory services, we offer Noise and Vibration Testing of Brake Components, a critical evaluation process that helps manufacturers optimize their products for optimal performance.

In this article, well delve into the significance of Noise and Vibration Testing of Brake Components, its benefits, and what you can expect from our comprehensive service. Whether youre an OEM manufacturer or a supplier looking to enhance your offerings, understanding the importance of this testing method will empower you to create products that meet the highest standards.

What is Noise and Vibration Testing of Brake Components?

Noise and Vibration Testing of Brake Components involves subjecting brake systems to rigorous evaluation under controlled laboratory conditions. Our team uses sophisticated equipment to simulate various driving scenarios, including braking cycles, acceleration, and deceleration. This process allows us to identify potential noise and vibration issues early on, ensuring that manufacturers can make informed design decisions before production begins.

Why is Noise and Vibration Testing of Brake Components essential for businesses?

Noise and Vibration Testing of Brake Components offers numerous benefits for manufacturers, including

Improved Safety By identifying noise and vibration issues, manufacturers can ensure their products meet stringent safety regulations, reducing the risk of accidents on the road.

Enhanced Performance Noise and vibration testing helps optimize brake systems for optimal performance, leading to improved fuel efficiency, reduced wear and tear, and enhanced overall driving experience.

Cost Savings By detecting issues early on, manufacturers can avoid costly redesigns, retooling, and production delays, saving time and resources in the long run.

Increased Customer Satisfaction Quiet and smooth brake operation contributes significantly to a vehicles overall appeal. Manufacturers that prioritize noise and vibration testing are more likely to satisfy customers expectations.

Key Benefits of Noise and Vibration Testing of Brake Components

Here are some key advantages of incorporating noise and vibration testing into your product development process

Early Issue Detection Identify potential noise and vibration issues early on, reducing the likelihood of costly redesigns or production delays.

Optimized Design Our expert team works with you to design brake systems that meet stringent performance requirements, ensuring optimal quiet operation.

Regulatory Compliance Meet or exceed safety regulations, minimizing the risk of product recalls and reputational damage.

Competitive Advantage Manufacturers who prioritize noise and vibration testing can differentiate themselves in a crowded market, offering products that stand out for their exceptional performance.

QA Common Questions about Noise and Vibration Testing of Brake Components

At Eurolab, weve answered some of the most frequently asked questions about our Noise and Vibration Testing of Brake Components service

What types of brake components can be tested?

We test a wide range of brake components, including pads, rotors, calipers, and master cylinders.

How do you simulate driving scenarios in your laboratory?

Our team uses advanced equipment to replicate various driving conditions, including braking cycles, acceleration, and deceleration.

Can you help us improve our existing products?

Yes! Our expert team works with manufacturers to identify areas for improvement and develop strategies for optimization.

How long does the testing process typically take?

The duration of the testing process varies depending on the specific requirements of your product. We work closely with clients to ensure that their needs are met efficiently.

Conclusion

Noise and Vibration Testing of Brake Components is an indispensable tool in the world of automotive engineering, helping manufacturers create products that meet the highest standards for performance, safety, and quality. At Eurolab, were committed to providing top-notch laboratory services that support your business goals. By partnering with us, youll benefit from our expertise, state-of-the-art equipment, and commitment to excellence.

Dont let noise and vibration issues compromise your products potential. Contact Eurolab today to learn more about our Noise and Vibration Testing of Brake Components service and discover how we can help you unlock the full performance capabilities of your brake systems.