Noise level measurement for electronic components

The Crucial Role of Noise Level Measurement for Electronic Components Why Your Business Cant Afford to Ignore It

In todays fast-paced and highly competitive world of electronics, the reliability and performance of electronic components are more crucial than ever. With increasingly complex designs and higher operating frequencies, even minor defects or anomalies can have a significant impact on the overall functioning of a device. This is where noise level measurement for electronic components comes into play a laboratory service that ensures your devices meet the required standards.

What is Noise Level Measurement for Electronic Components?

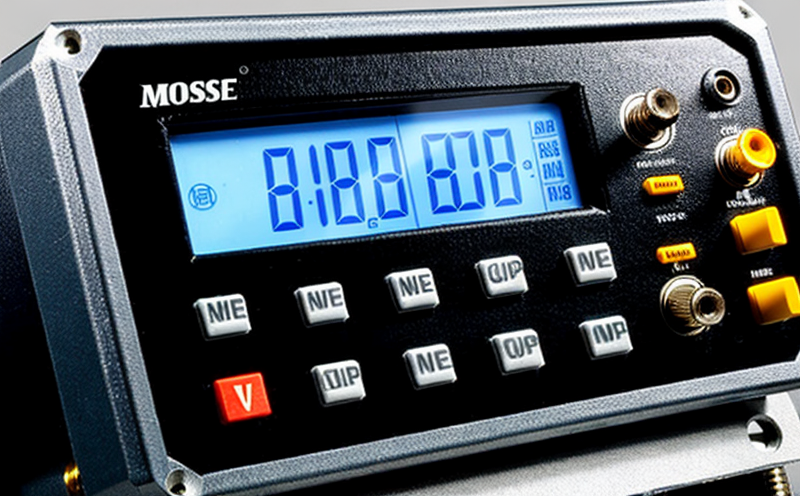

Noise level measurement, also known as noise analysis or electromagnetic interference (EMI) testing, is a critical process that assesses the amount of unwanted electrical energy present in an electronic component. This energy can take various forms, including radio-frequency interference (RFI), conducted noise, and electromagnetic radiation. By measuring these unwanted signals, manufacturers can identify potential issues before they affect the performance or reliability of their products.

At Eurolab, our team of experts specializes in providing precise and accurate noise level measurement services for electronic components. Our cutting-edge equipment and state-of-the-art facilities enable us to deliver comprehensive reports that help you optimize your products design and functionality.

The Benefits of Noise Level Measurement for Electronic Components

Incorporating noise level measurement into your quality control process offers numerous advantages, including

Improved Product Reliability By identifying potential issues early on, manufacturers can reduce the risk of defective products reaching the market. This not only saves time and resources but also enhances customer satisfaction.

Enhanced Performance Unwanted electrical energy can cause malfunctions, errors, or even complete system failures. Noise level measurement ensures that your components operate as intended, leading to improved overall performance and efficiency.

Reduced EMI Compliance Issues Many industries, such as aerospace, automotive, and medical, have strict regulations regarding electromagnetic interference (EMI). By conducting noise level measurements, manufacturers can ensure compliance with these regulations and avoid costly reworks or recalls.

Increased Customer Confidence When customers know that your products have undergone rigorous testing for noise levels, theyre more likely to trust the quality and reliability of your devices.

Competitive Advantage Companies that prioritize noise level measurement demonstrate their commitment to excellence and are more likely to gain market share and customer loyalty.

Cost Savings Identifying and addressing potential issues early on can save manufacturers significant amounts in rework, repair, or replacement costs.

The Eurolab Difference

At Eurolab, we understand the importance of precision and accuracy when it comes to noise level measurement. Our team consists of experienced professionals with extensive knowledge of electronic components and industry-specific regulations. We use state-of-the-art equipment to ensure that our measurements are reliable and repeatable.

Our comprehensive noise level measurement services include

Conducted noise analysis

Radiated emission testing (RE)

Immunity testing

Shielding effectiveness evaluation

We also offer customized solutions tailored to your specific needs, ensuring that you receive accurate and actionable data to inform your product development decisions.

Frequently Asked Questions

What types of electronic components can be measured for noise levels?

Eurolab provides noise level measurement services for a wide range of electronic components, including integrated circuits (ICs), printed circuit boards (PCBs), and discrete devices.

How often should I conduct noise level measurements?

Its recommended to perform regular noise level measurements throughout the product development cycle, especially during critical design phases or when introducing new technologies.

What are the typical timeframes for noise level measurement services?

Turnaround times vary depending on the complexity of the project and the type of testing required. Our team will work closely with you to ensure that your project is completed efficiently and effectively.

Can I choose the specific testing standards or regulations I want to comply with?

Yes, Eurolab can tailor our services to meet industry-specific regulations or custom requirements.

Do you offer consulting or advisory services related to noise level measurement?

Yes, our team is available to provide expert guidance on implementing effective noise level measurement strategies and interpreting results.

Conclusion

In todays electronics landscape, noise level measurement for electronic components has become an essential step in ensuring product reliability, performance, and compliance. At Eurolab, were committed to providing accurate, comprehensive, and actionable data that helps manufacturers optimize their products and stay ahead of the competition. By partnering with us, you can

Enhance your products quality and performance

Improve customer satisfaction and loyalty

Reduce rework and repair costs

Gain a competitive edge in the market

Dont compromise on noise level measurement trust Eurolab to deliver expert results that drive business success.